Please see the Transcriber’s Notes at the end of this text.

New original cover art included with this eBook is granted to the public domain.

Faithfully yours

Charles T. Porter

Engineering Reminiscences

CONTRIBUTED TO

“Power” and “American Machinist”

BY

CHARLES T. PORTER

Honorary Member of The American Society of Mechanical Engineers

Author of “A Treatise on the Richards Steam-engine Indicator

and the Development and Application of Force in the

Steam-engine,” 1874; “Mechanics and Faith,” 1885

REVISED AND ENLARGED

FIRST EDITION

FIRST THOUSAND

NEW YORK

JOHN WILEY & SONS

London: CHAPMAN & HALL, Limited

1908

Copyright 1908

BY

CHARLES T. PORTER

THIS BOOK IS DEDICATED

TO THE MEMORY OF

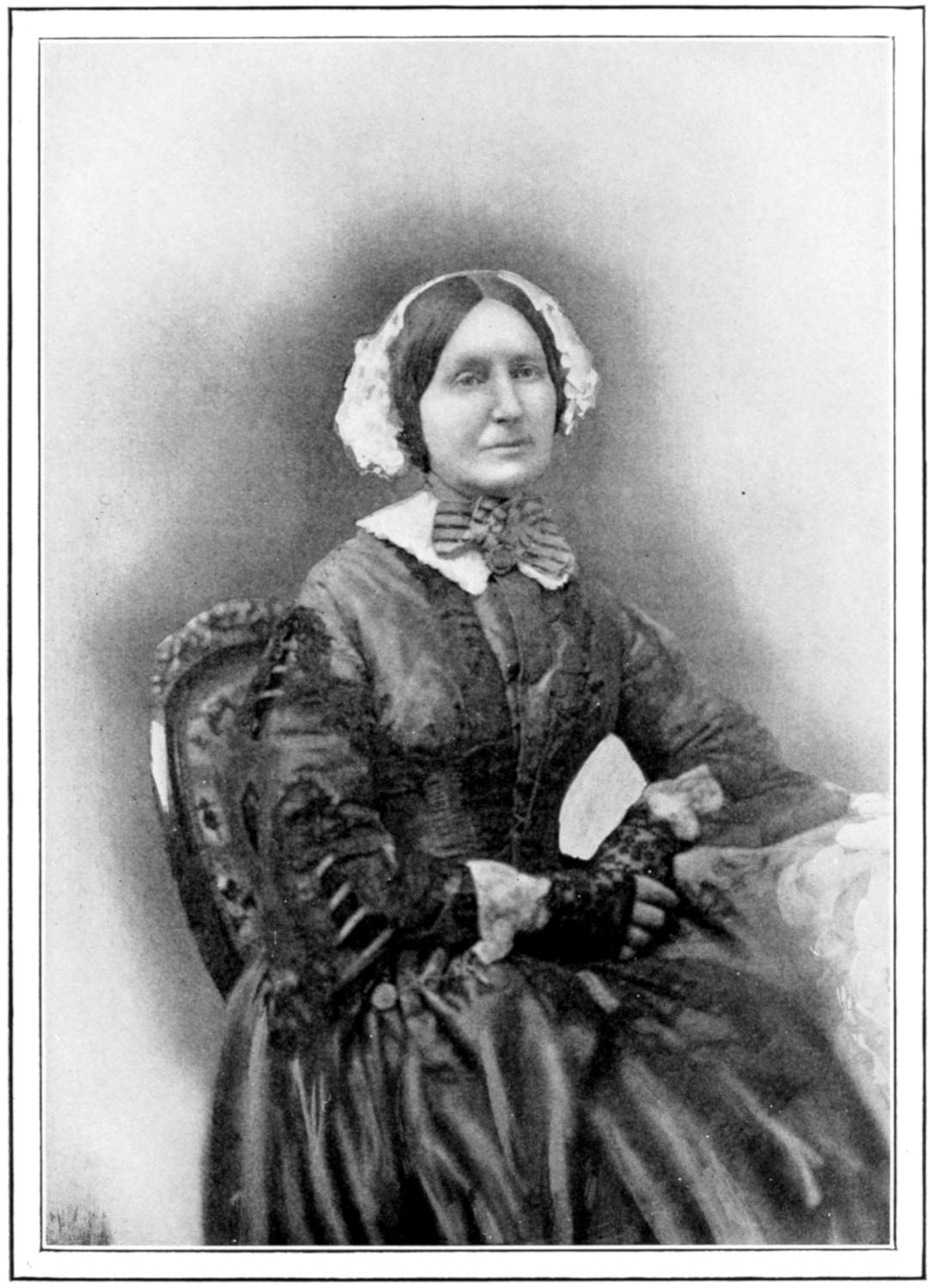

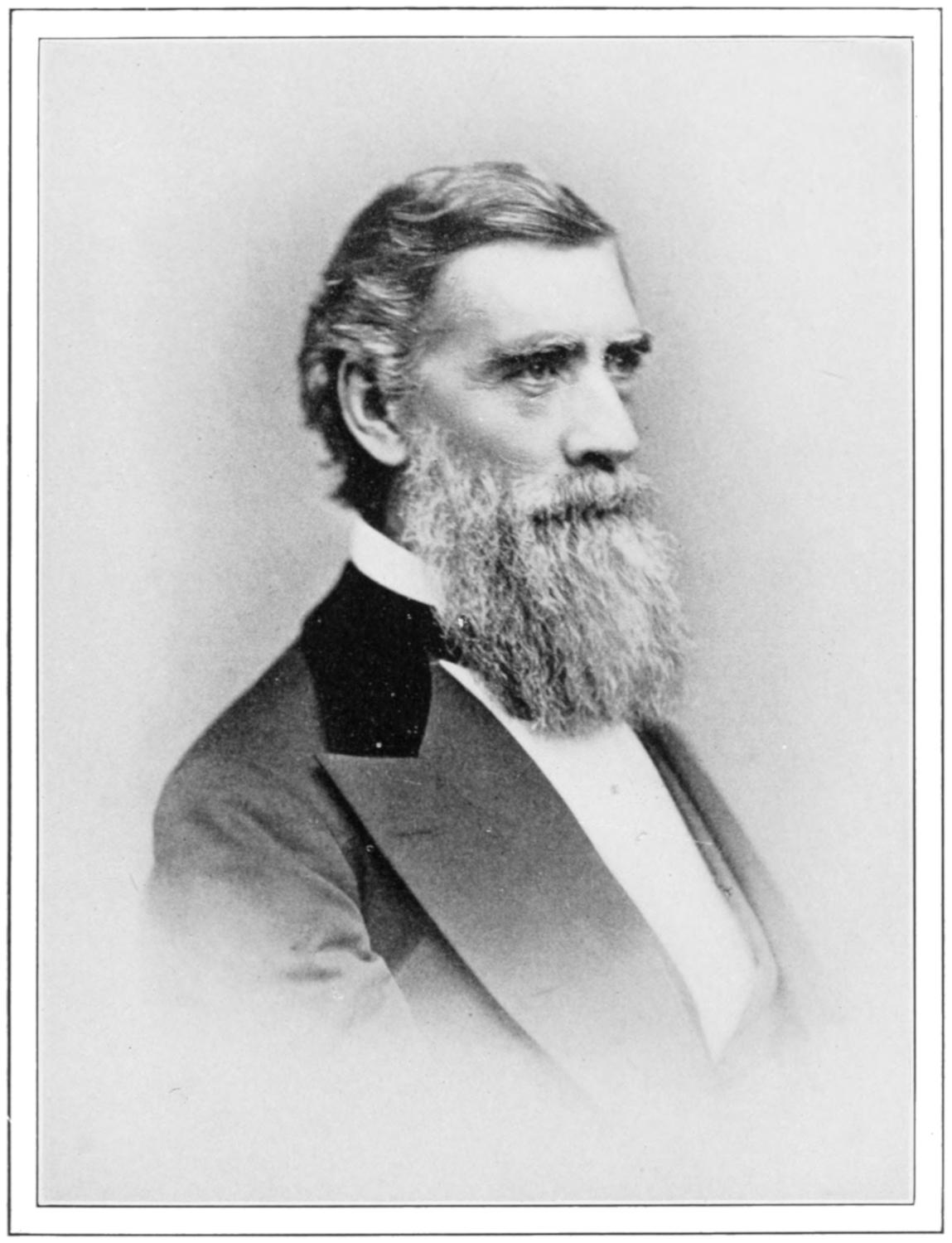

MY FATHER AND MOTHER

My Father

My Mother

[iii]

PREFACE

A word of explanation seems due to both the reader and myself.

The idea of writing these reminiscences did not originate with me. I was invited to write them by Mr. F. R. Low, the editor of Power. This invitation I declined, saying that I felt averse to writing a story in which I must be the central figure. Mr. Low replied that I should regard it as a duty I owed to the profession. Engineers demanded to know the origin and early development of the high speed system of steam engineering. I was the only person who could meet this demand; no one else possessed the necessary information.

I felt obliged to yield to this view, and can only ask the reader to imagine that I am writing about somebody else.

C. T. P.

Montclair, N. J.,

December, 1907.

[vii]

TABLE OF CONTENTS

| CHAPTER I | |

| PAGE | |

| Birth, Parentage and Education. Experience in the Practice of Law. Introduction to Centrifugal Force. Invention and Operation of a Stone-dressing Machine | 1 |

| CHAPTER II | |

| The Evolution and Manufacture of the Central Counterpoise Governor. Introduction of Mr. Richards | 17 |

| CHAPTER III | |

| Invention and Application of my Marine Governor | 34 |

| CHAPTER IV | |

| Engineering Conditions in 1860. I meet Mr. Allen. Mr. Allen’s Inventions. Analysis of the Allen Link | 42 |

| CHAPTER V | |

| Invention of the Richards Indicator. My Purchase of the Patent. Plan my London Exhibition. Engine Design. Ship Engine Bed to London, and sail myself | 58 |

| CHAPTER VI | |

| Arrival in London. Conditions I found there. Preparations and Start | 65 |

| CHAPTER VII | |

| My London Exhibit, its Success, but what was the matter? Remarkable Sale of the Engine | 71 |

| CHAPTER VIII[viii] | |

| Sale of Governors. Visit from Mr. Allen. Operation of the Engine Sold to Easton, Amos & Sons. Manufacture of the Indicator. Application on Locomotives | 80 |

| CHAPTER IX | |

| Designs of Horizontal Engine Beds. Engine Details. Presentation of the Indicator at the Newcastle Meeting of the British Association for the Advancement of Science | 93 |

| CHAPTER X | |

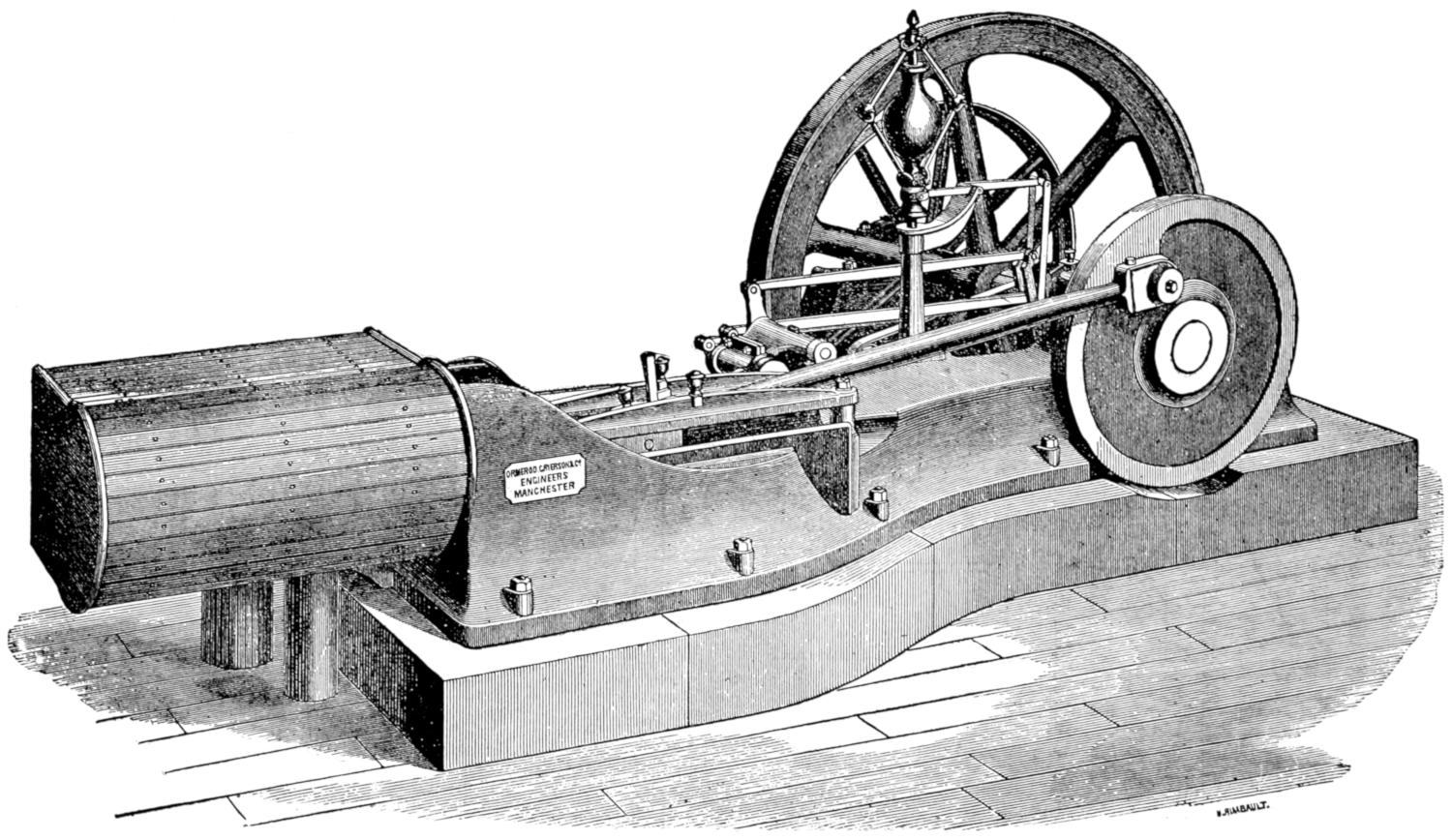

| Contract with Ormerod, Grierson & Co. Engine for Evan Leigh, Son & Co. Engine for the Oporto Exhibition. Getting Home from Portugal | 101 |

| CHAPTER XI | |

| Trouble with the Evan Leigh Engine. Gear Patterns from the Whitworth Works. First Order for a Governor. Introduction of the Governor into Cotton Mills. Invention of my Condenser. Failure of Ormerod, Grierson & Co. | 113 |

| CHAPTER XII | |

| Introduction to the Whitworth Works. Sketch of Mr. Whitworth. Experience in the Whitworth Works. Our Agreement Which was never Executed. First Engine in England Transmitting Power by a Belt | 122 |

| CHAPTER XIII | |

| The French Exposition of 1867. Final Break with Mr. Whitworth | 139 |

| CHAPTER XIV | |

| Study of the Action of Reciprocating Parts. Important Help from Mr. Frederick J. Slade. Paper before Institution of Mechanical Engineers. Appreciation of Zerah Colburn. The Steam Fire Engine in England | 153 |

| CHAPTER XV | |

| Preparations for Returning to America. Bright Prospects | 165 |

| CHAPTER XVI | |

| Return to America. Disappointment. My Shop. The Colt Armory Engine Designed by Mr. Richards. Appearance of Mr. Goodfellow. My Surface Plate Work. Formation of a Company | 173 |

| CHAPTER XVII[ix] | |

| Mr. Allen’s Invention of his Boiler. Exhibition at the Fair of the American Institute in 1870 | 190 |

| CHAPTER XVIII | |

| Demonstration to the Judges of Action of Reciprocating Parts. Explanation of this Action. Mr. Williams’ Instrument for Exhibiting this Action | 198 |

| CHAPTER XIX | |

| Boiler Tests in Exhibition of 1871. We Lose Mr. Allen. Importance of Having a Business Man as President. Devotion of Mr. Hope | 208 |

| CHAPTER XX | |

| Close of the Engine Manufacture in Harlem. My Occupation During a Three Years’ Suspension | 219 |

| CHAPTER XXI | |

| Production of an Original Surface Plate | 233 |

| CHAPTER XXII | |

| Efforts to Resume the Manufacture. I Exhibit the Engine to Mr. Holley. Contract with Mr. Phillips. Sale of Engine to Mr. Peters | 238 |

| CHAPTER XXIII | |

| Experience as Member of the Board of Judges at the Philadelphia Centennial Exhibition | 245 |

| CHAPTER XXIV | |

| Engine Building in Newark. Introduction of Harris Tabor | 259 |

| CHAPTER XXV | |

| Engine for the Cambria Iron and Steel Company | 271 |

| CHAPTER XXVI[x] | |

| My Downward Progress | 275 |

| CHAPTER XXVII | |

| My Last Connection with the Company | 325 |

| CHAPTER XXVIII | |

| The Fall and Rise of the Southwark Foundry and Machine Company. Popular Appreciation of the High-speed Engine | 331 |

[xi]

LIST OF ILLUSTRATIONS

| PAGE | ||

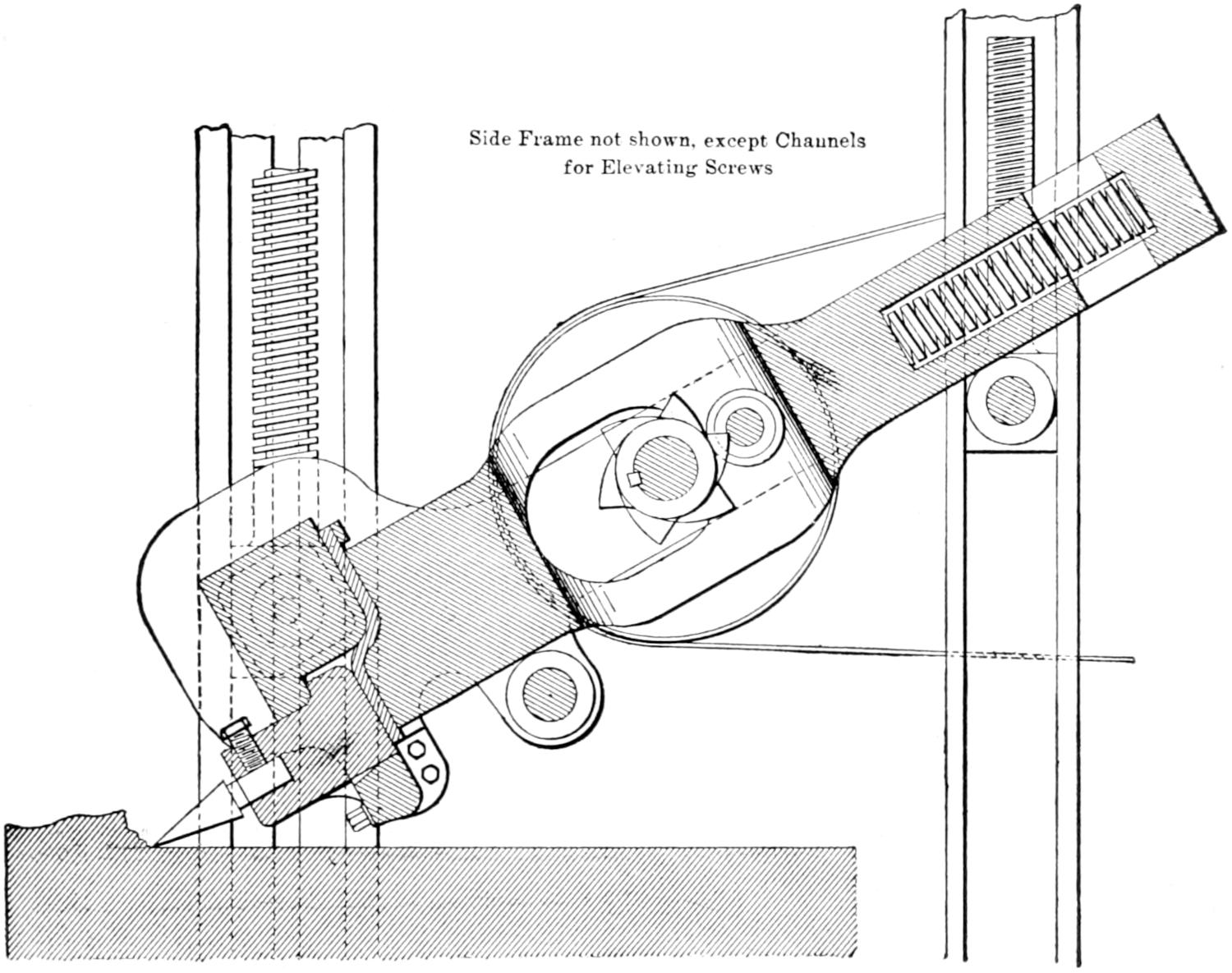

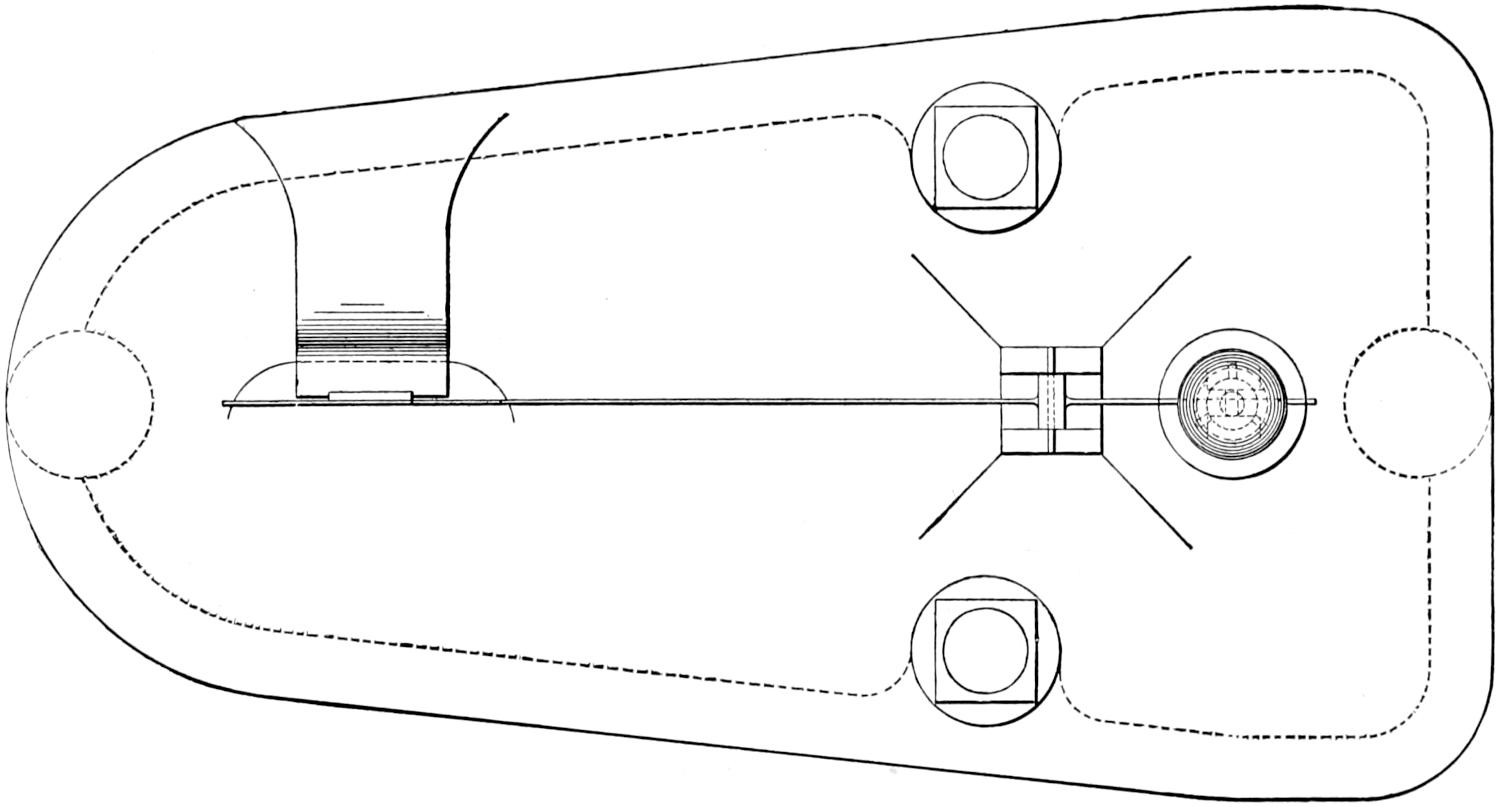

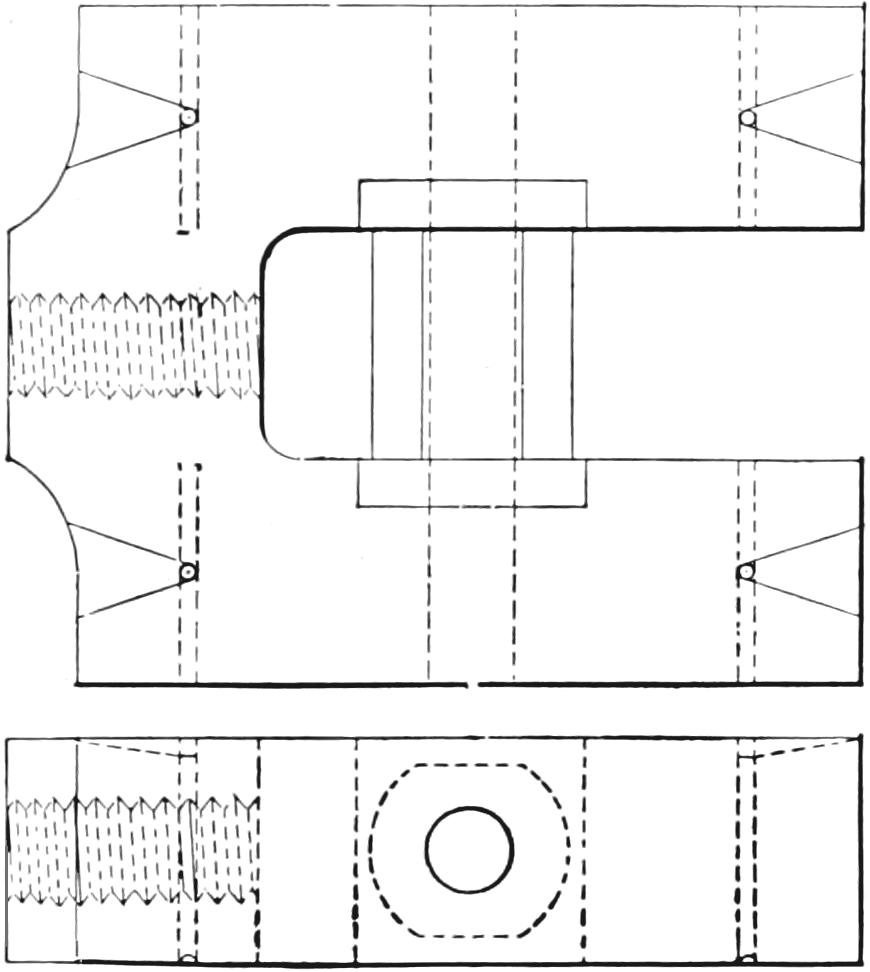

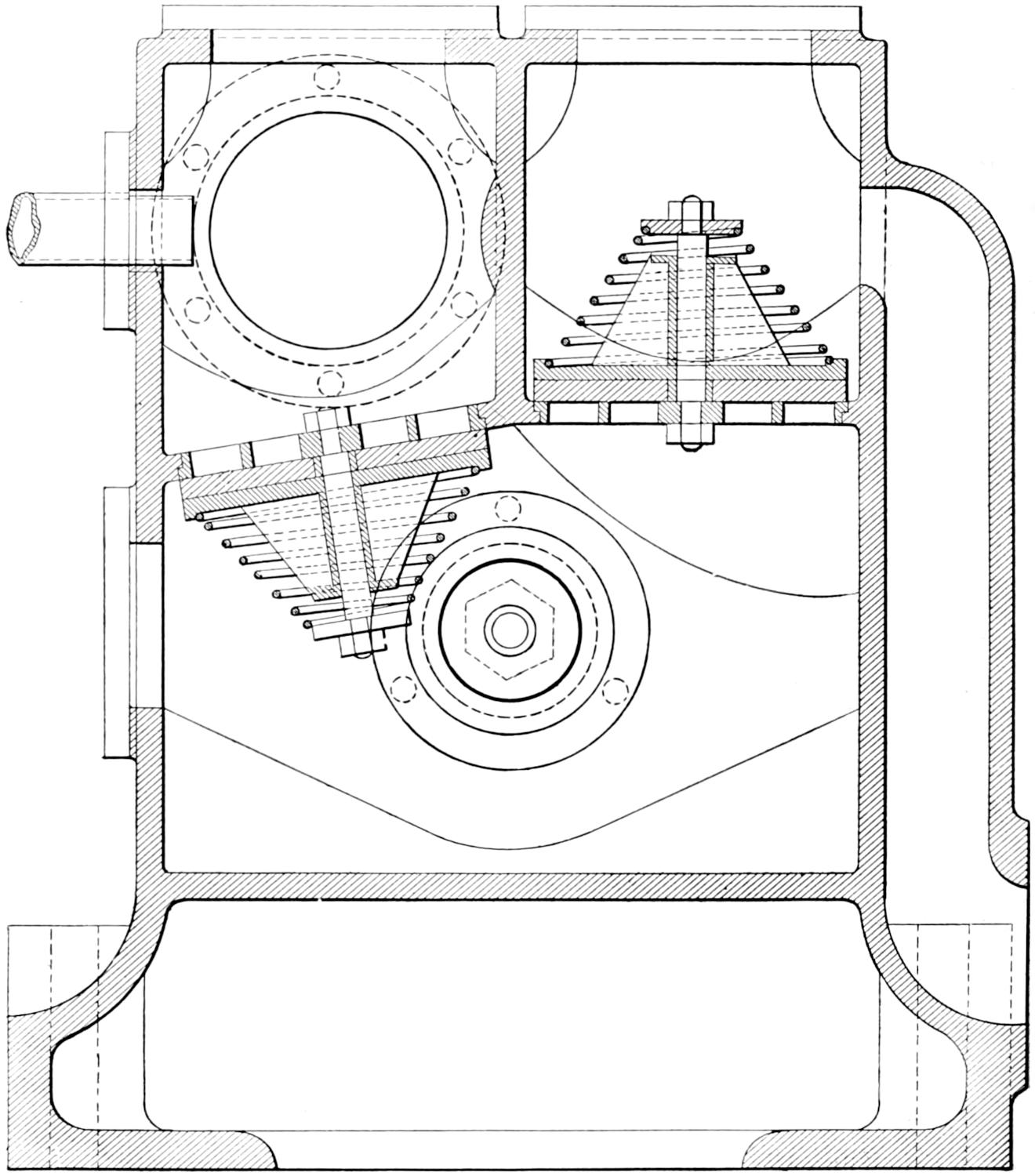

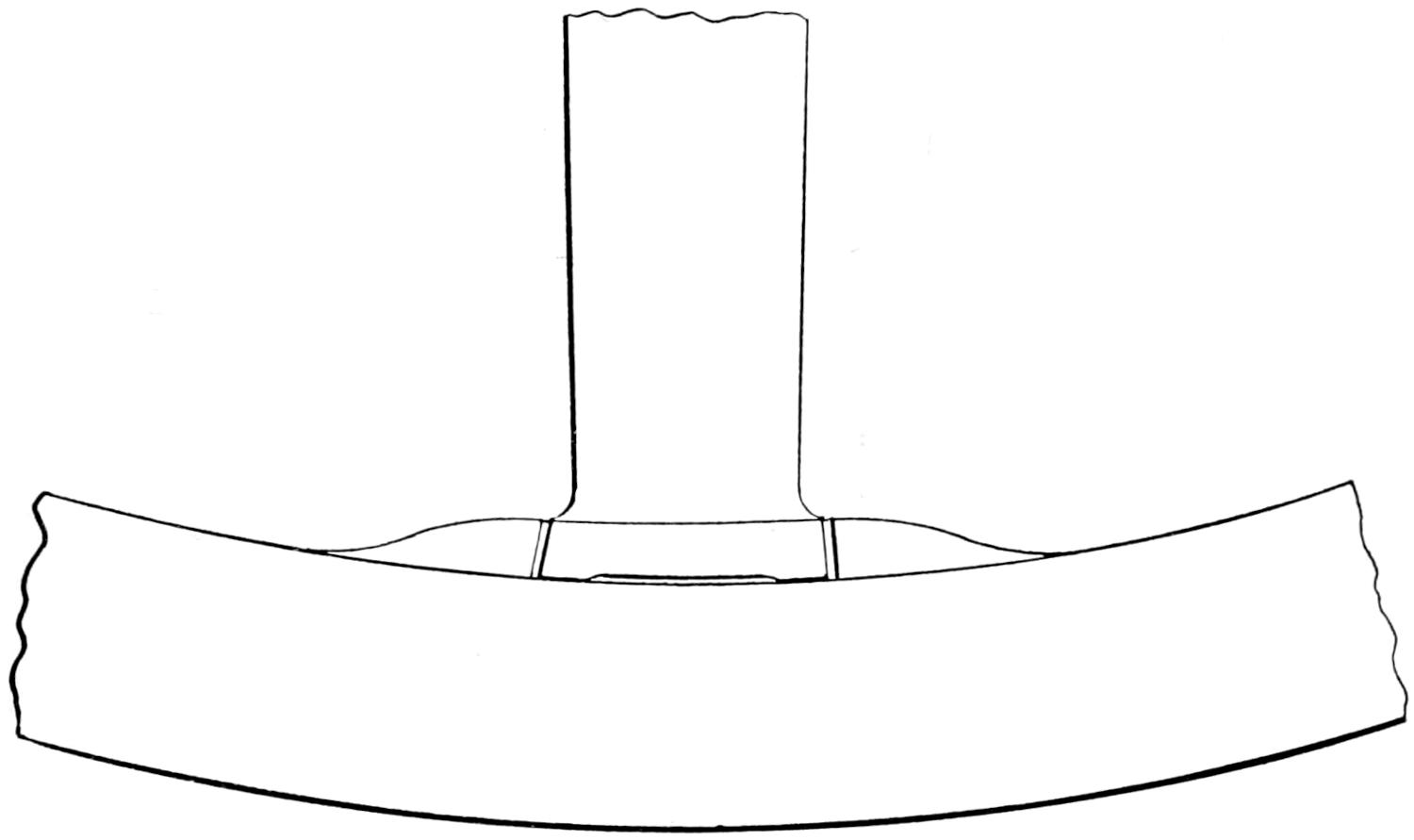

| 1. | My First Mechanical Drawing. Longitudinal Section of my Stone-dressing Machine | 7 |

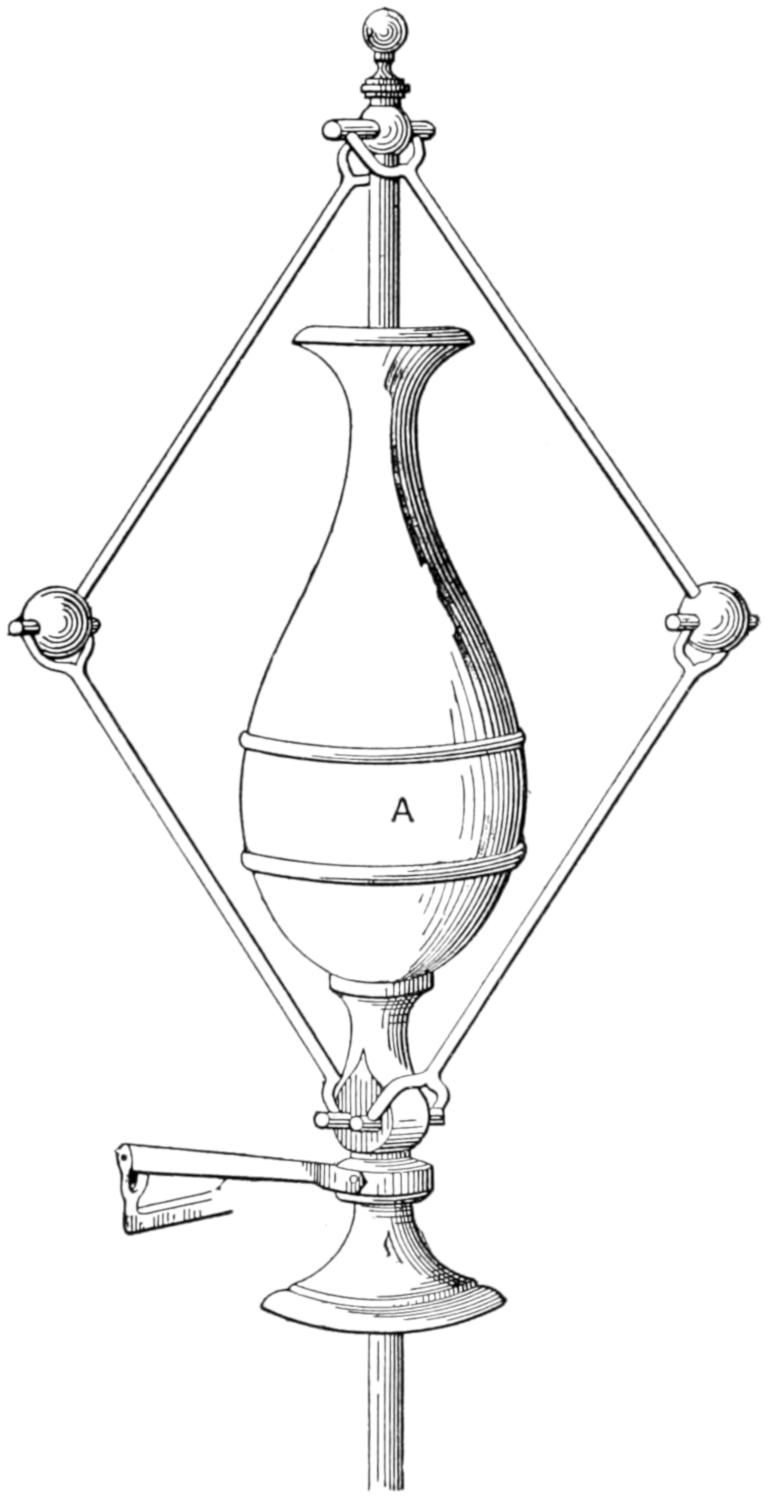

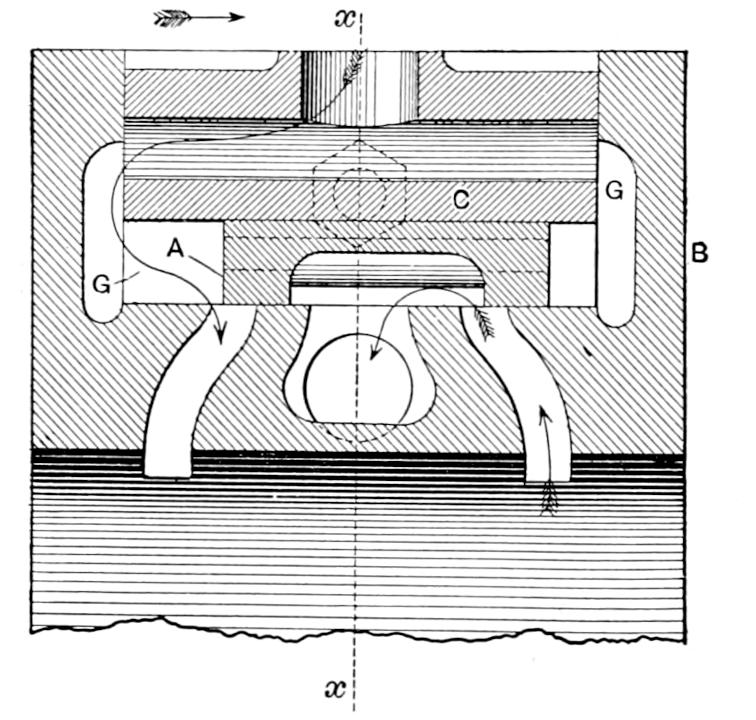

| 2. | The First Porter Governor | 21 |

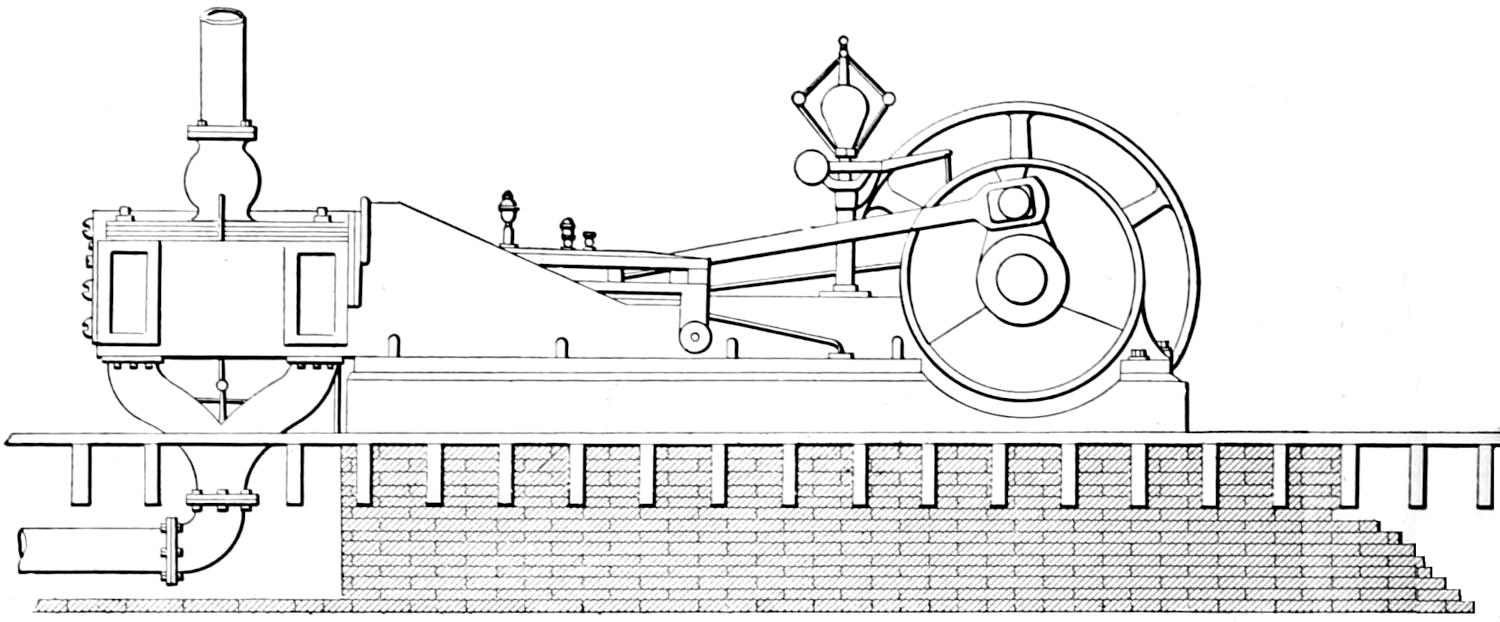

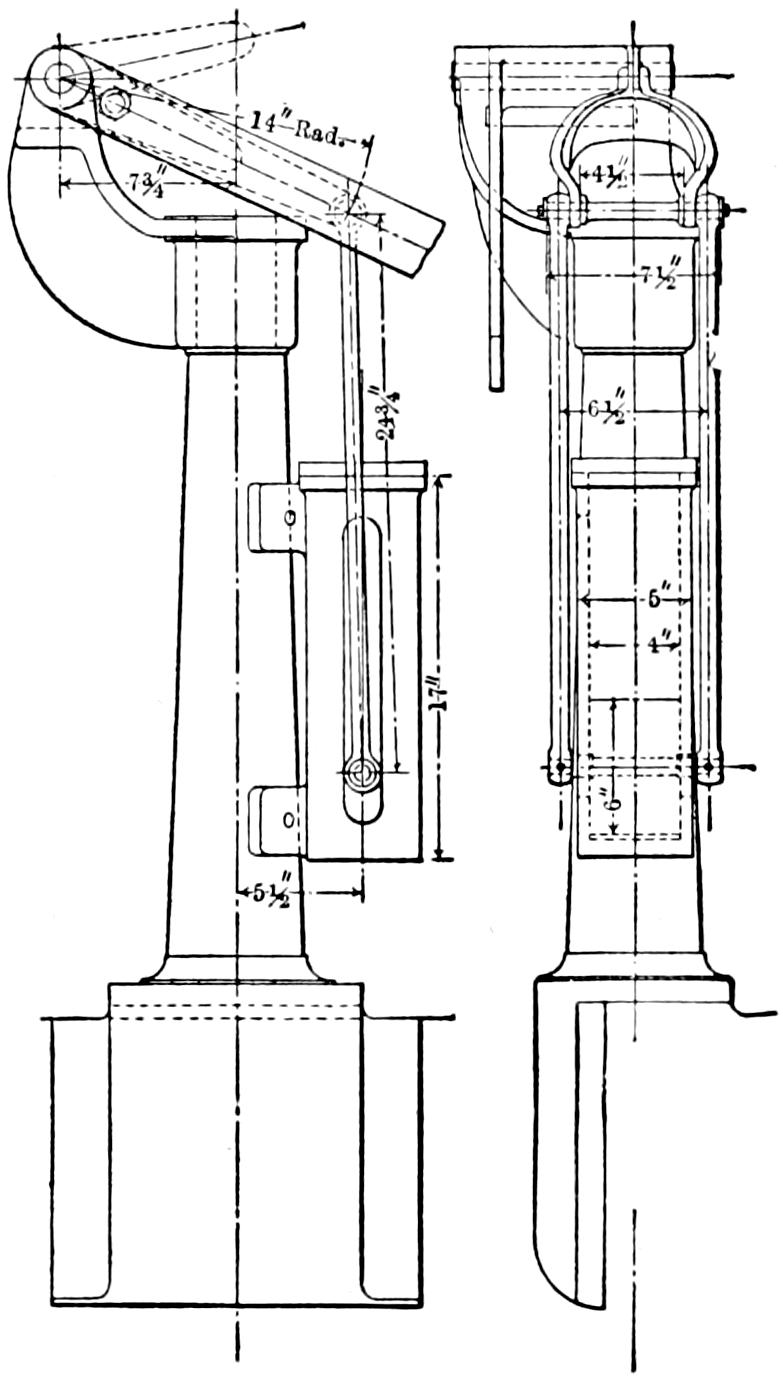

| 3. | The Porter Marine Governor | 37 |

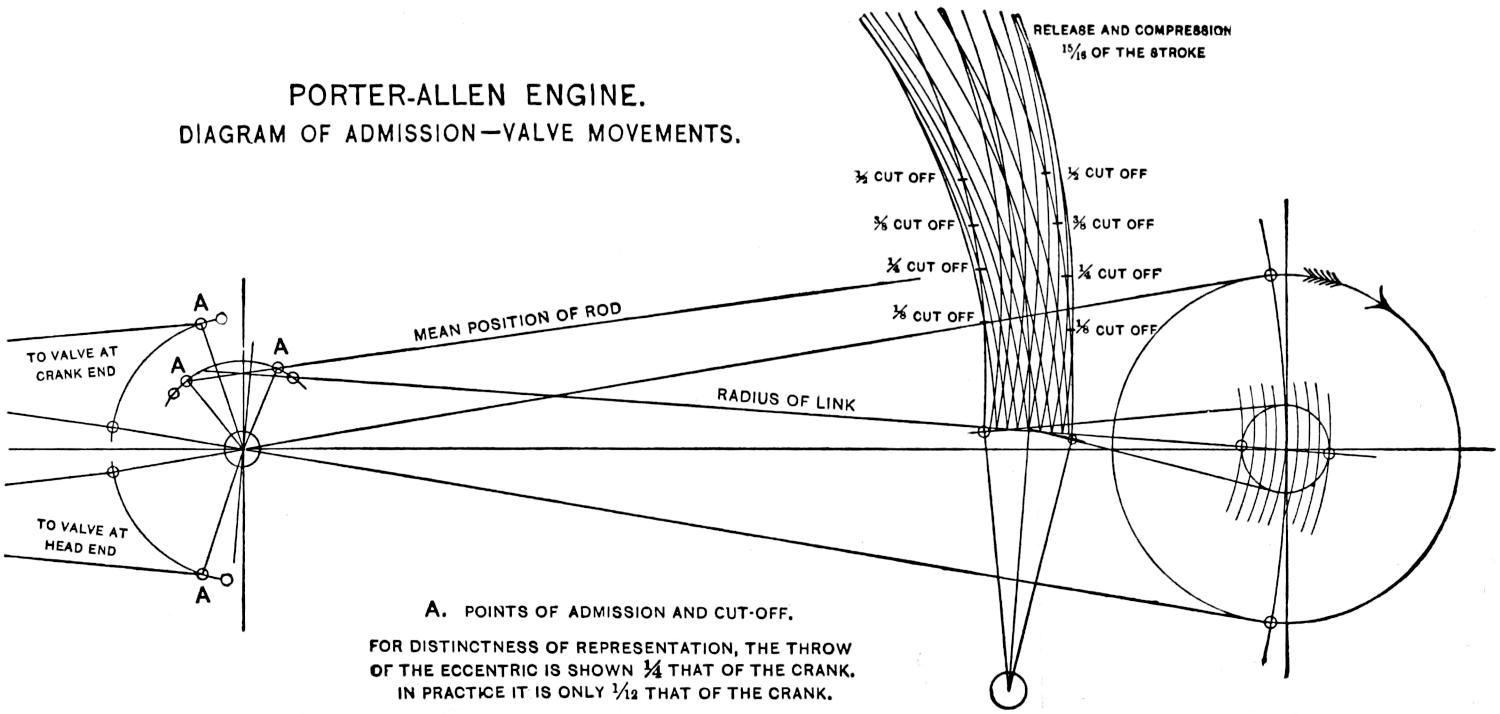

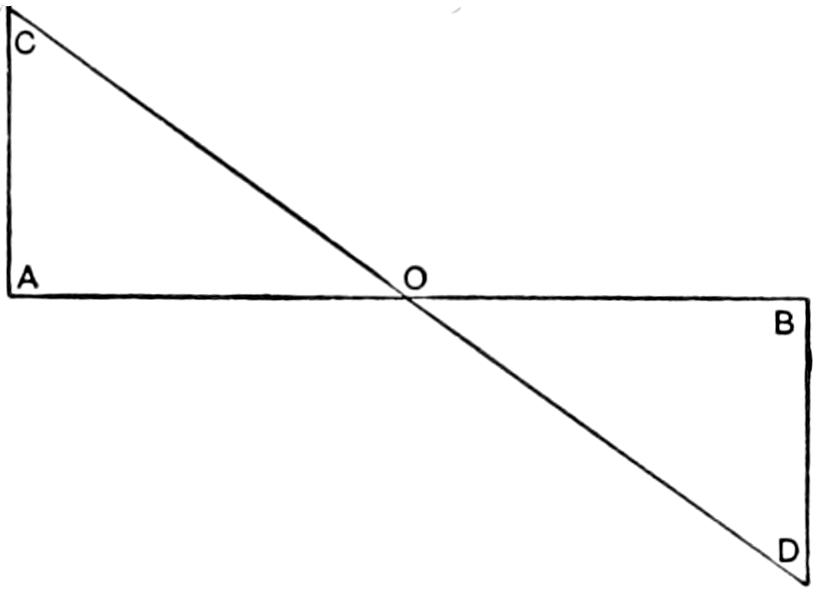

| 4. | Porter-Allen Engine. Diagram of Admission—Valve Movements | 48 |

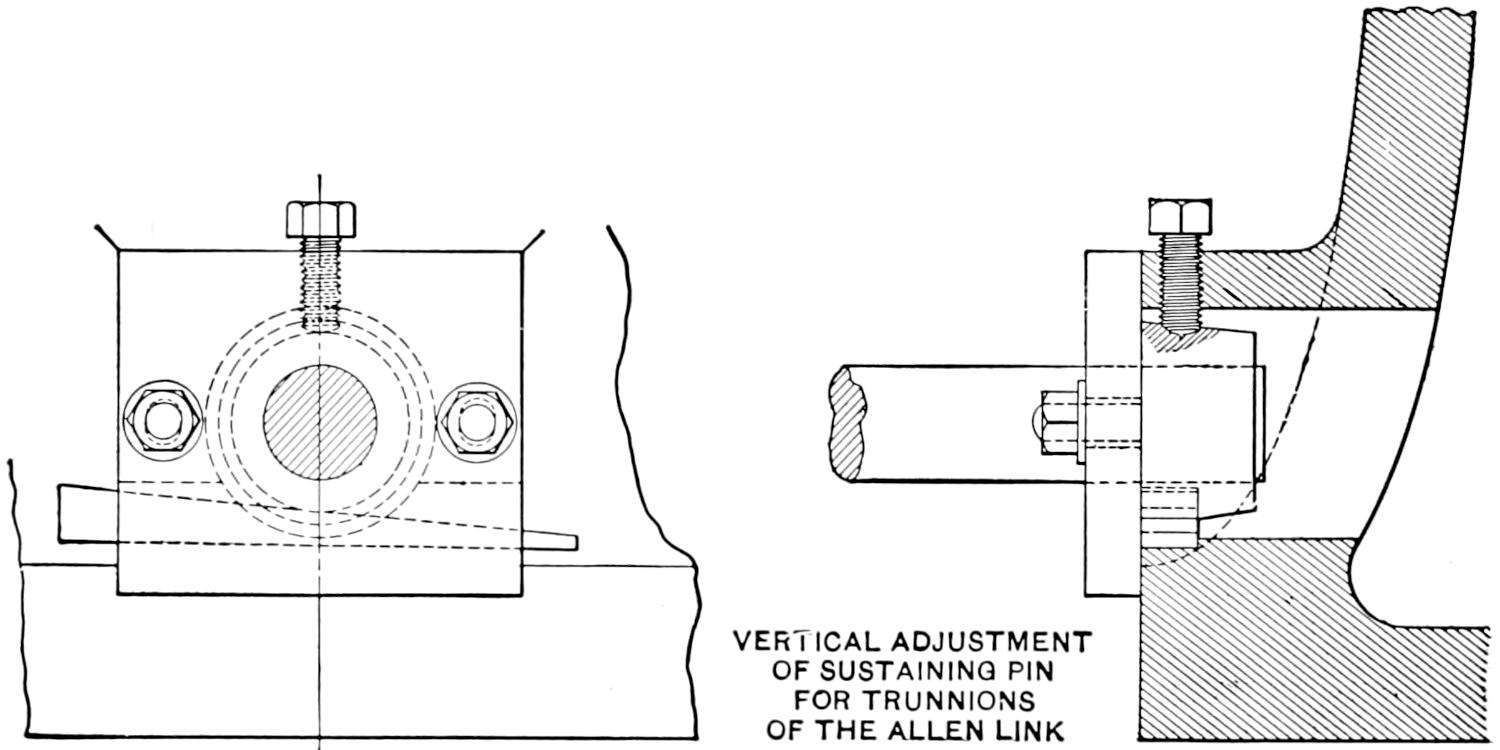

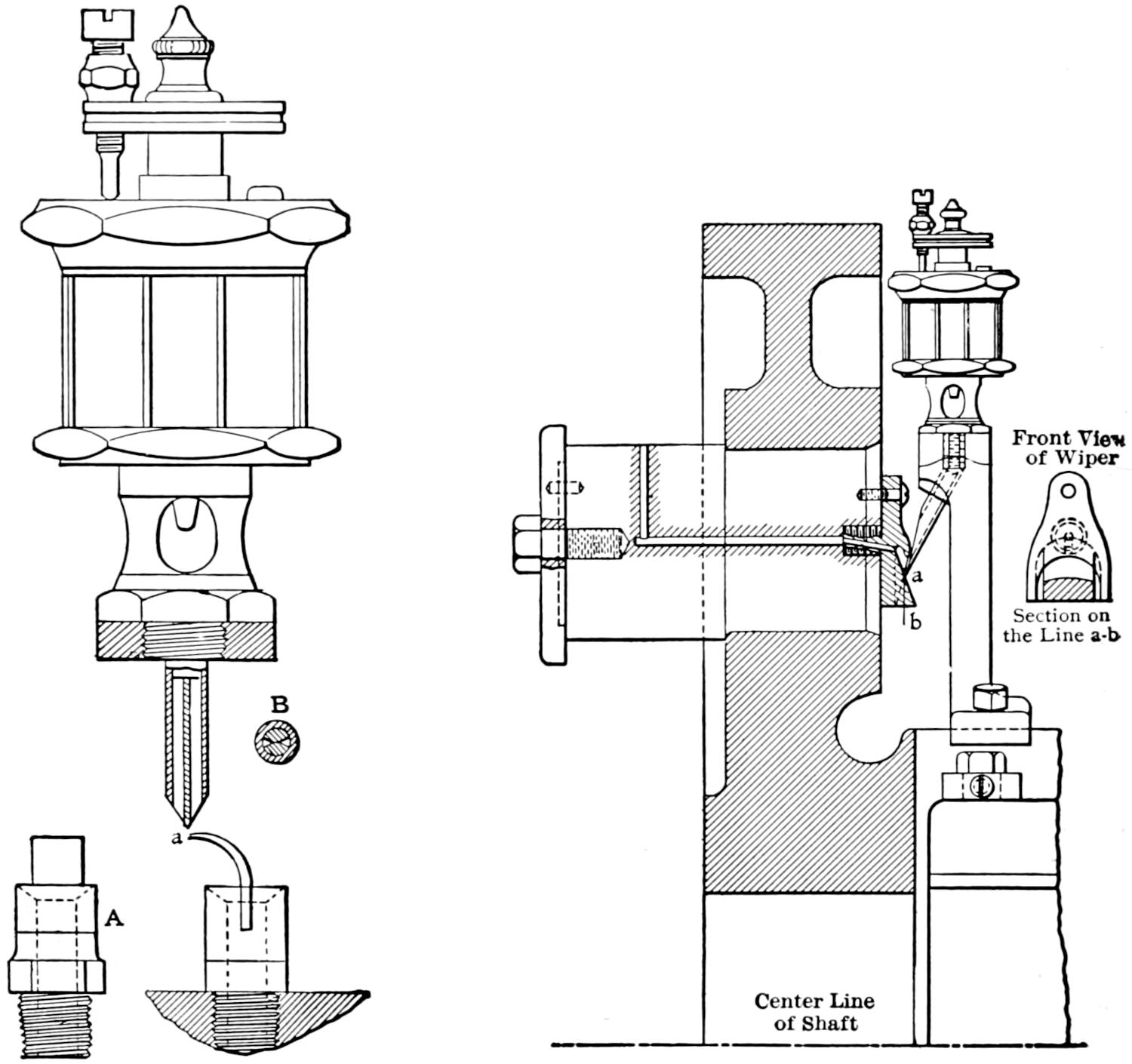

| 5. | Vertical Adjustment of Sustaining Pin for Trunnions of the Allen Link | 52 |

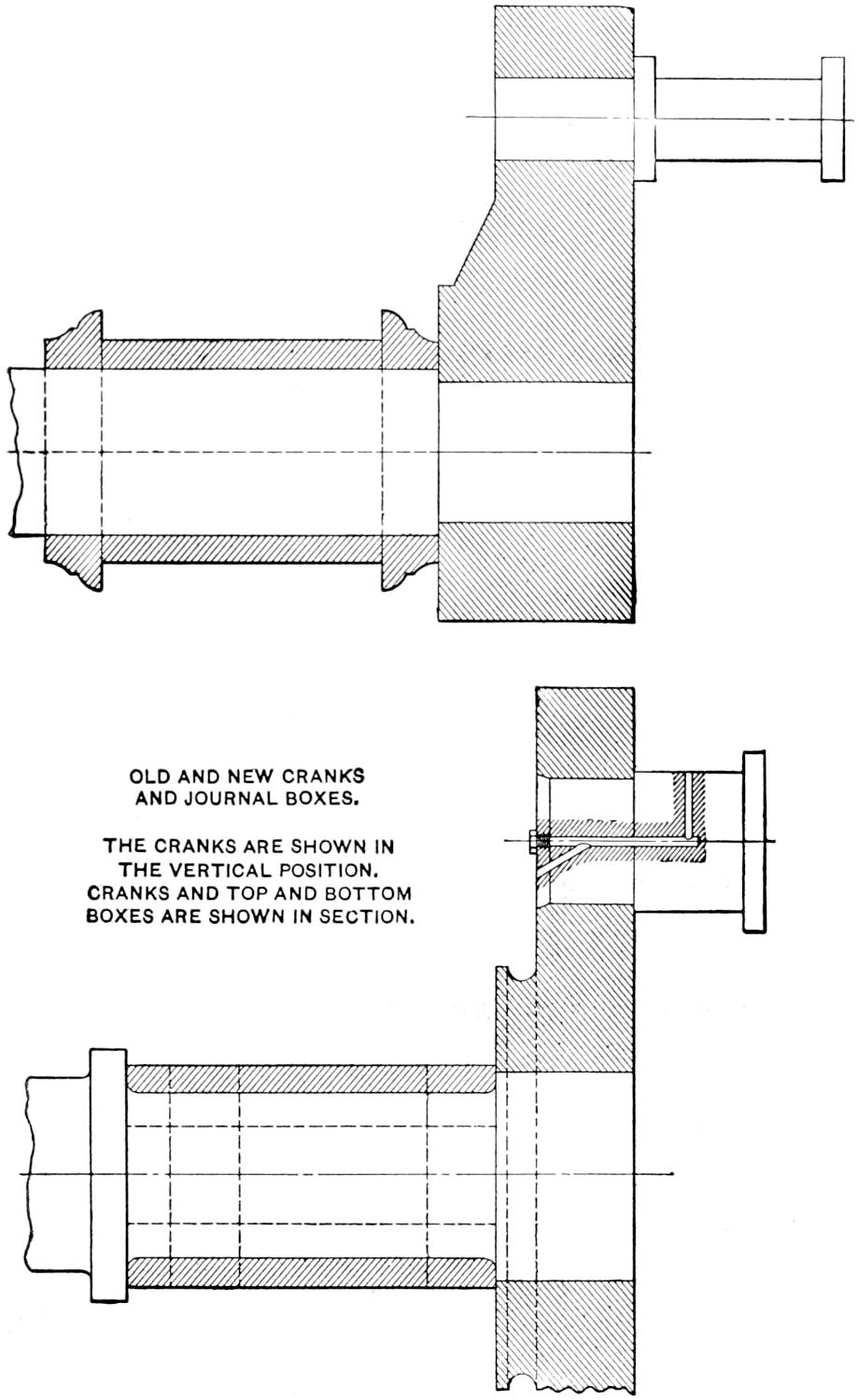

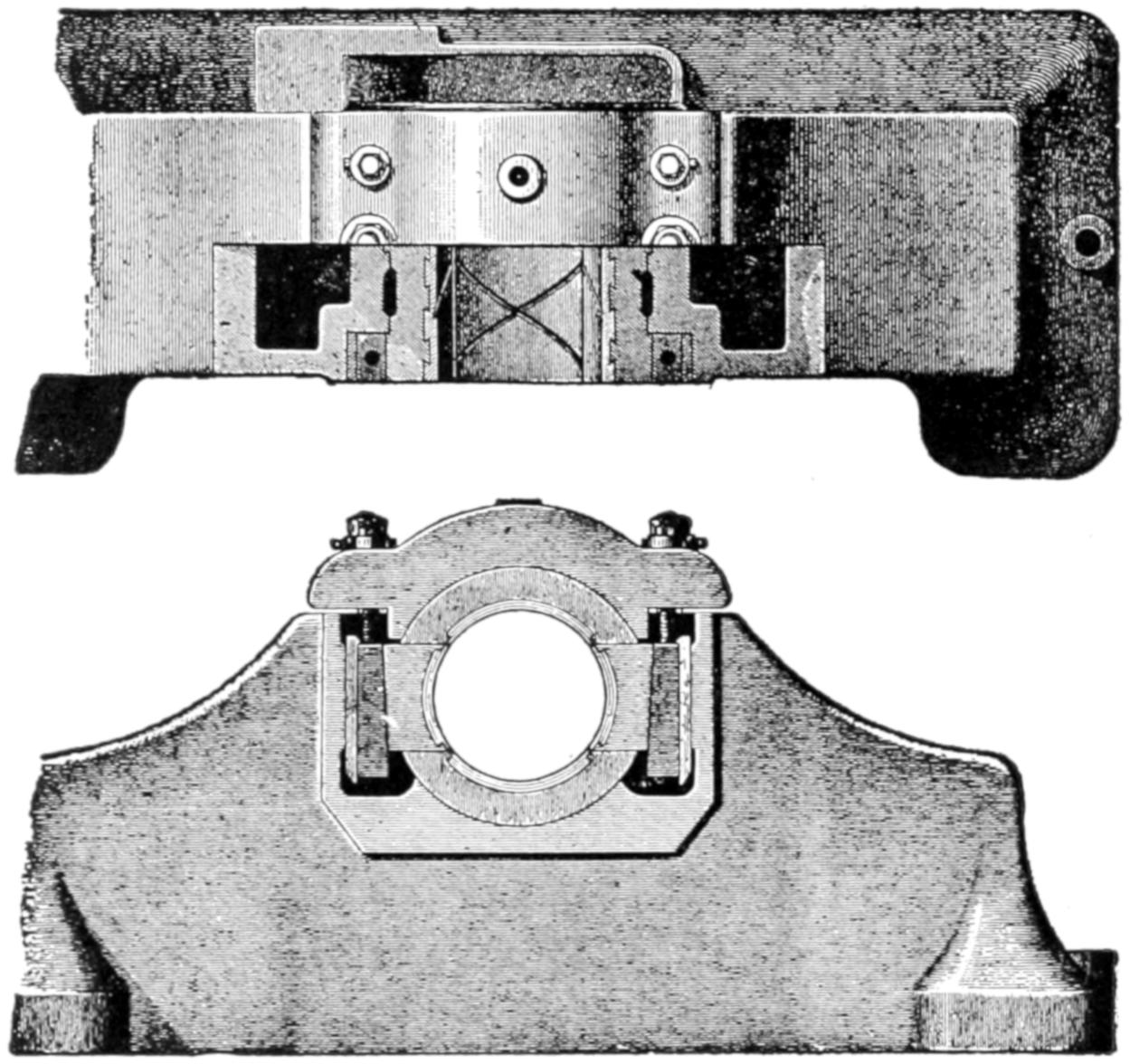

| 6. | My Improvement in Cranks and Journal Boxes | 54 |

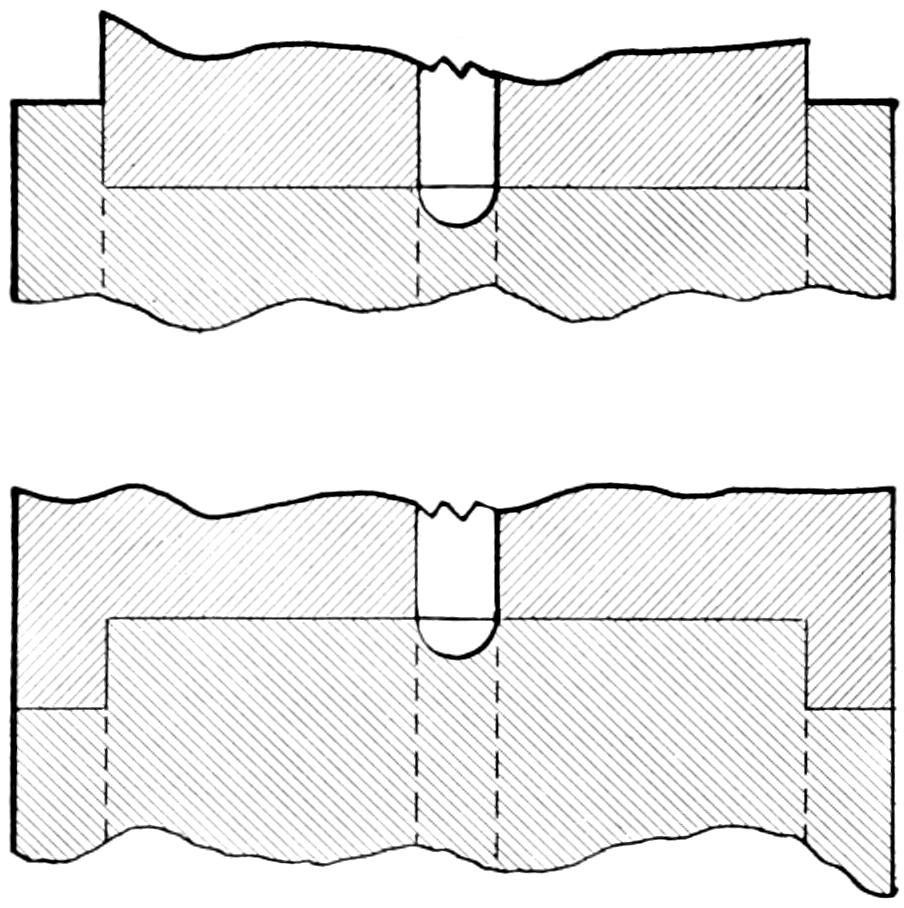

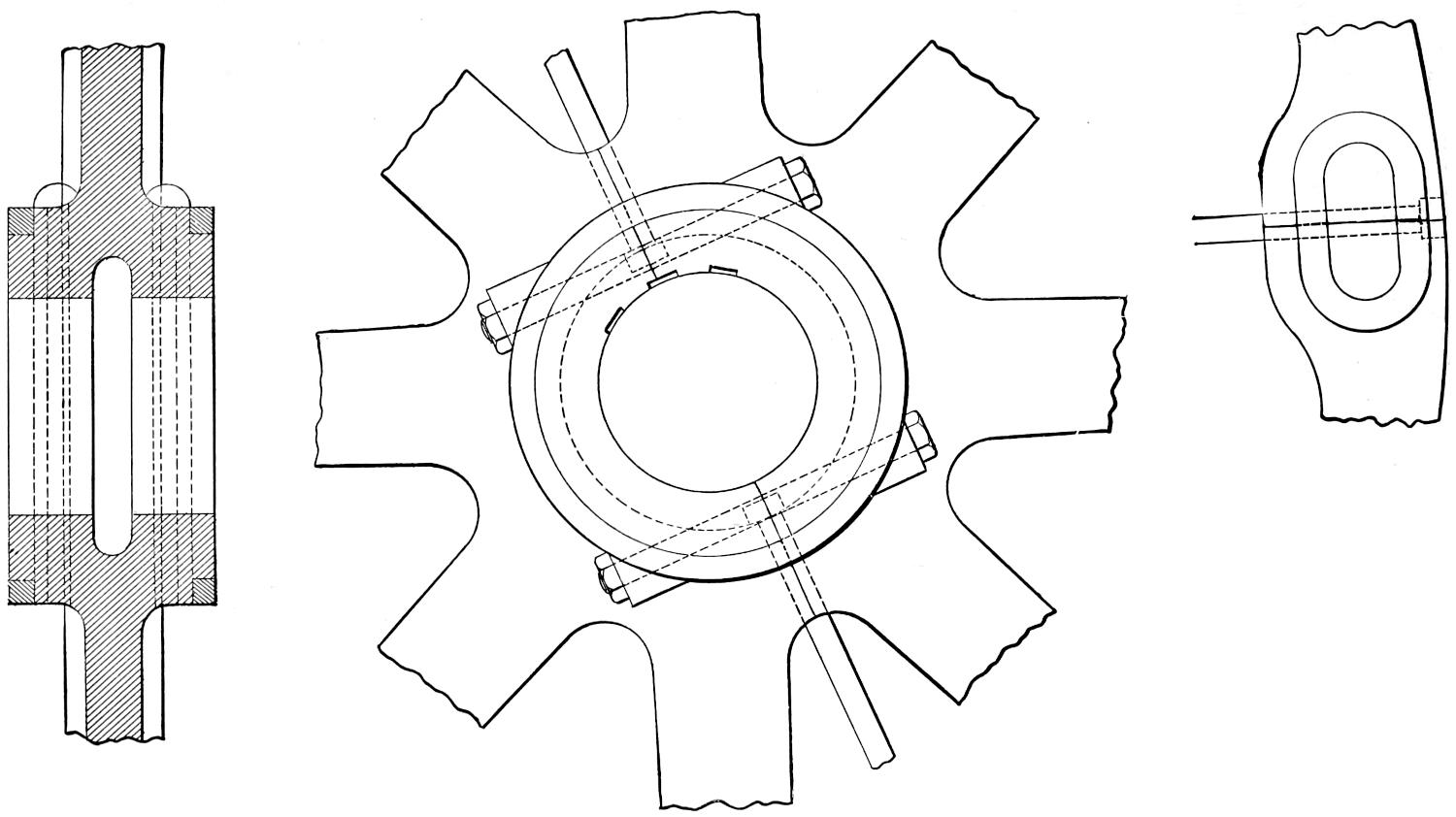

| 7. | My Improvement in Eccentrics | 56 |

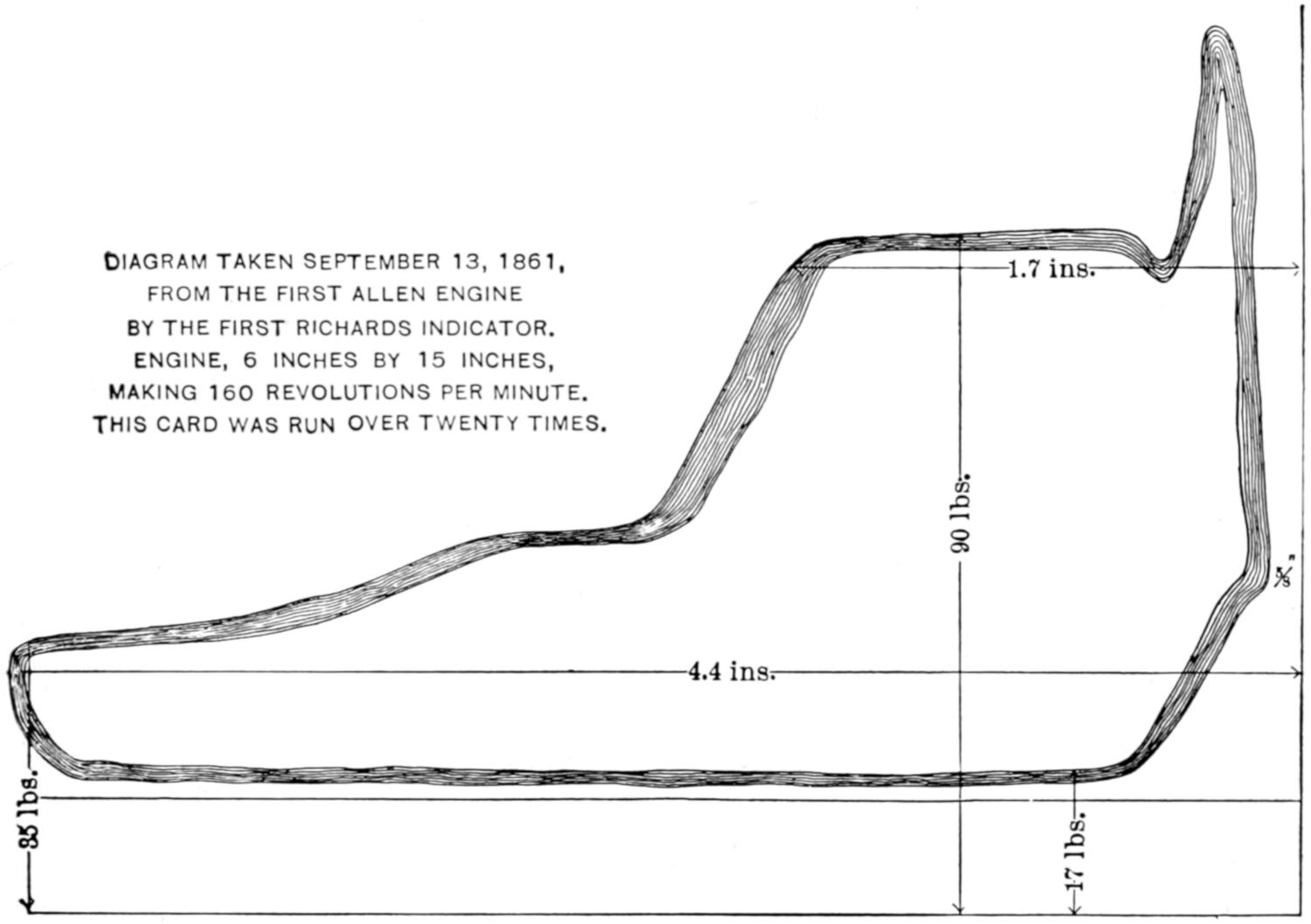

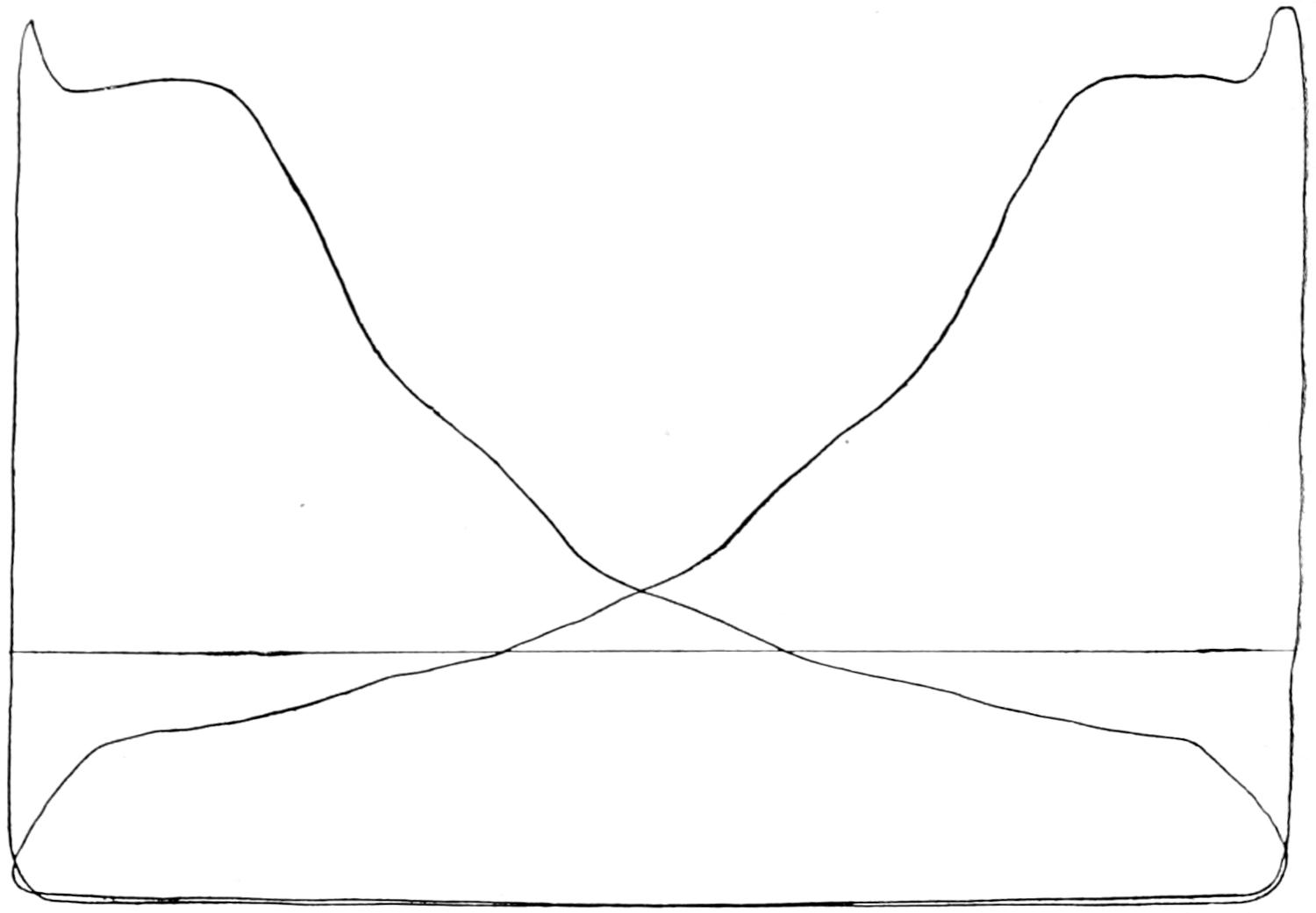

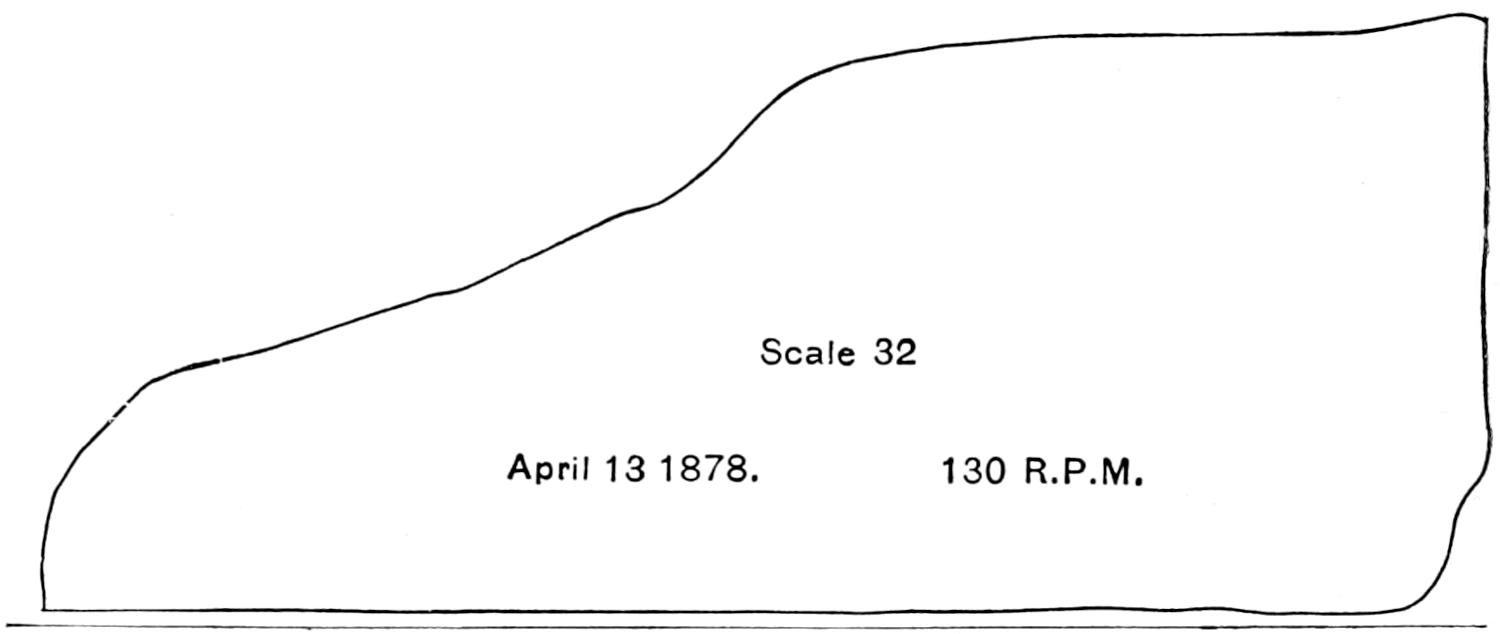

| 8. | Diagram from the First Allen Engine taken with the First Richards Indicator | 59 |

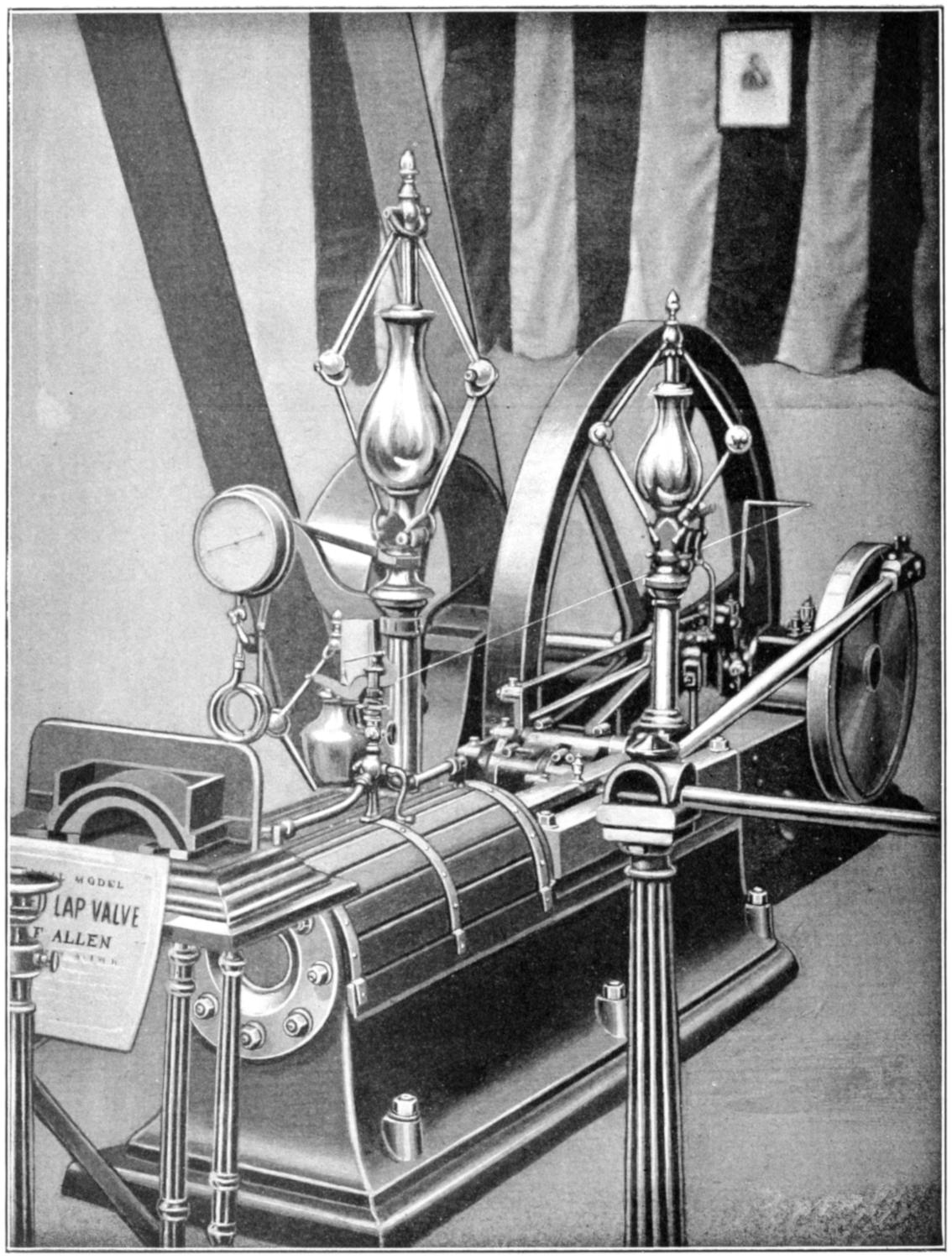

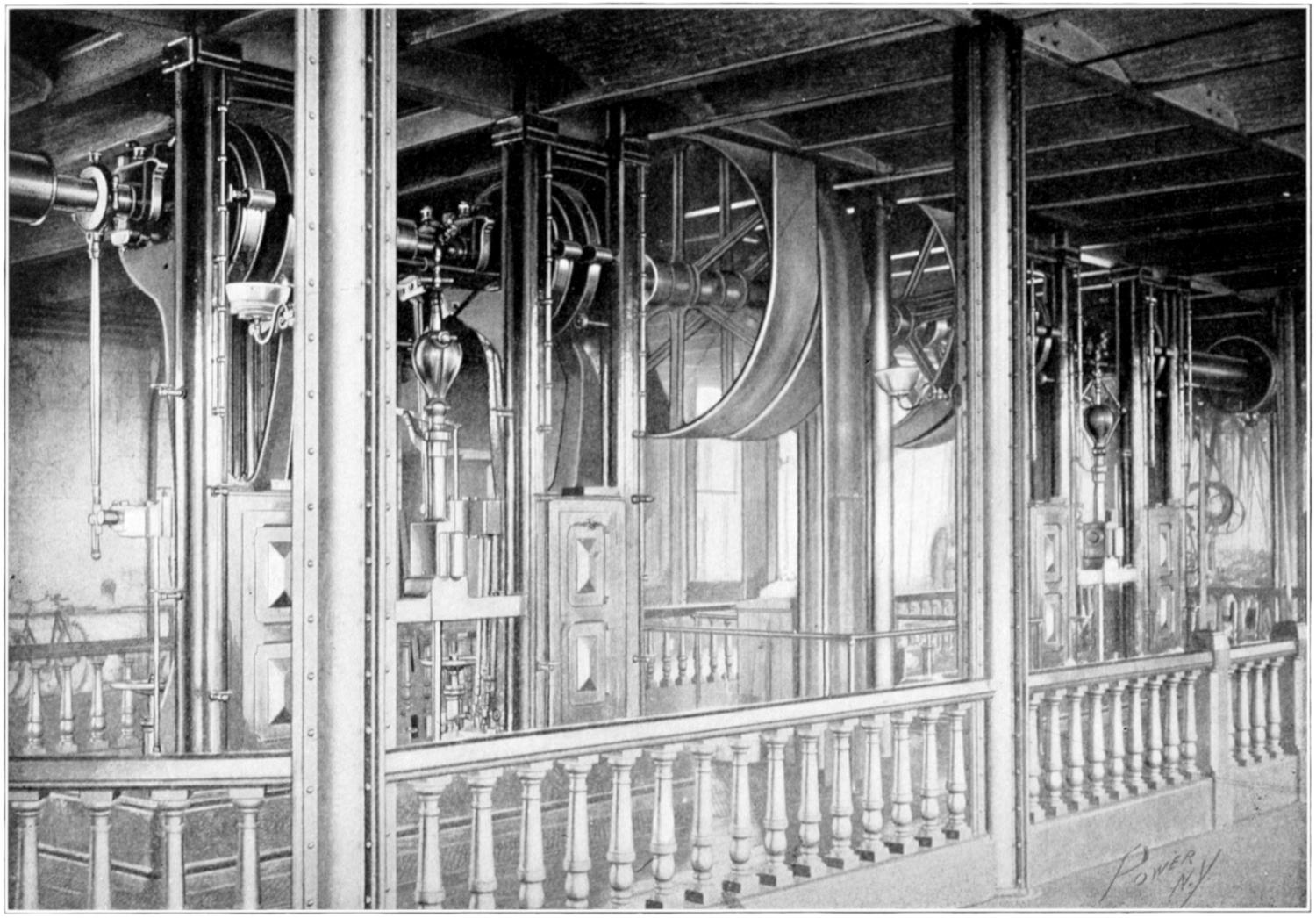

| 9. | Mr. Porter’s Exhibit at the London International Exhibition, 1862 | 71 |

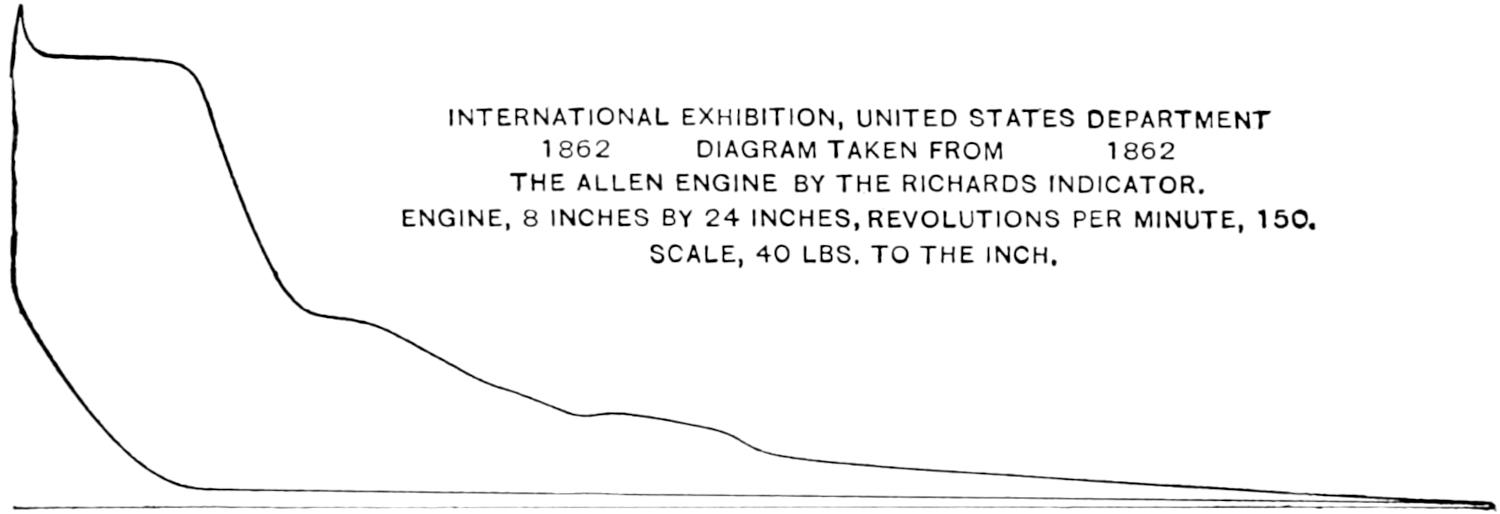

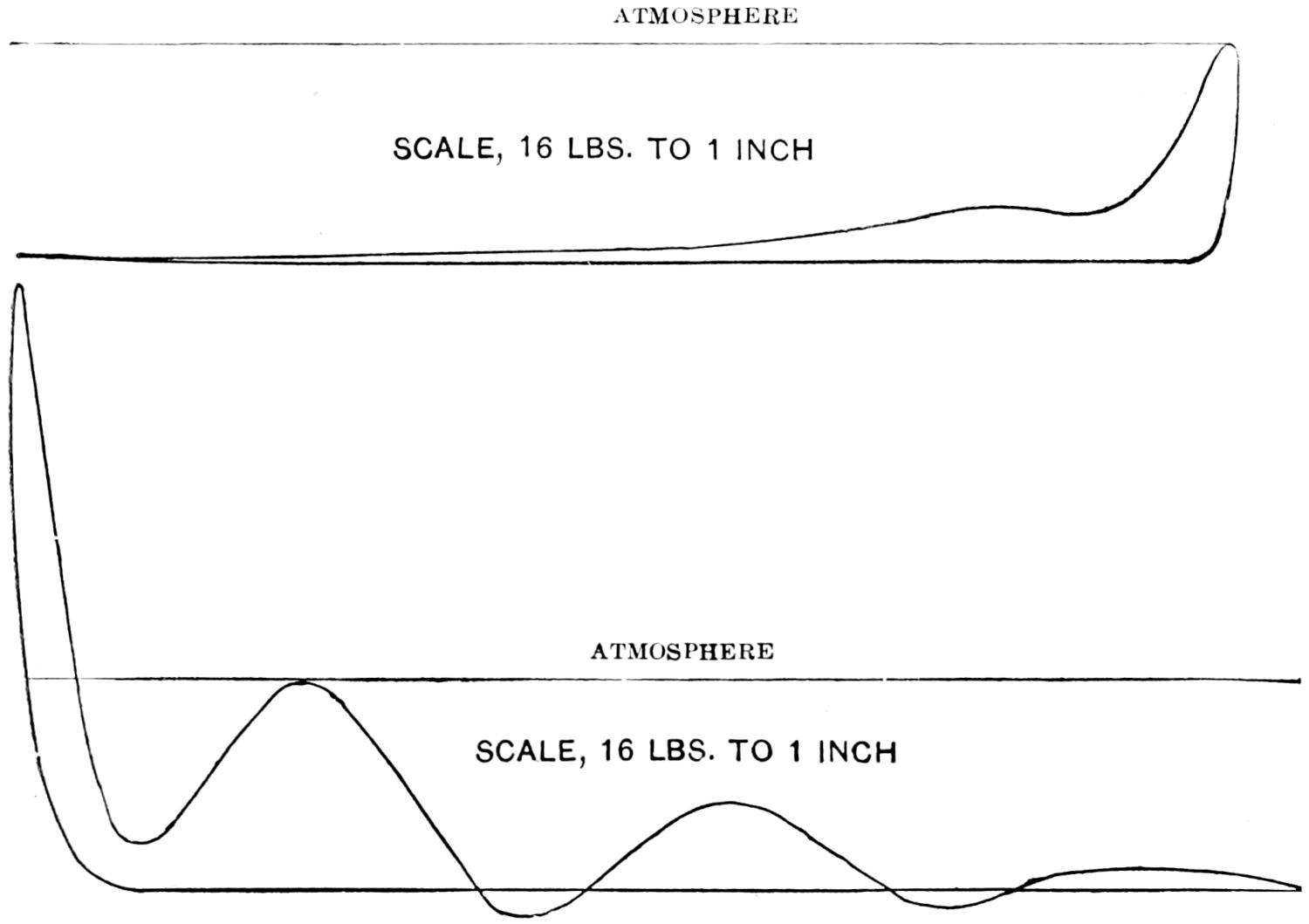

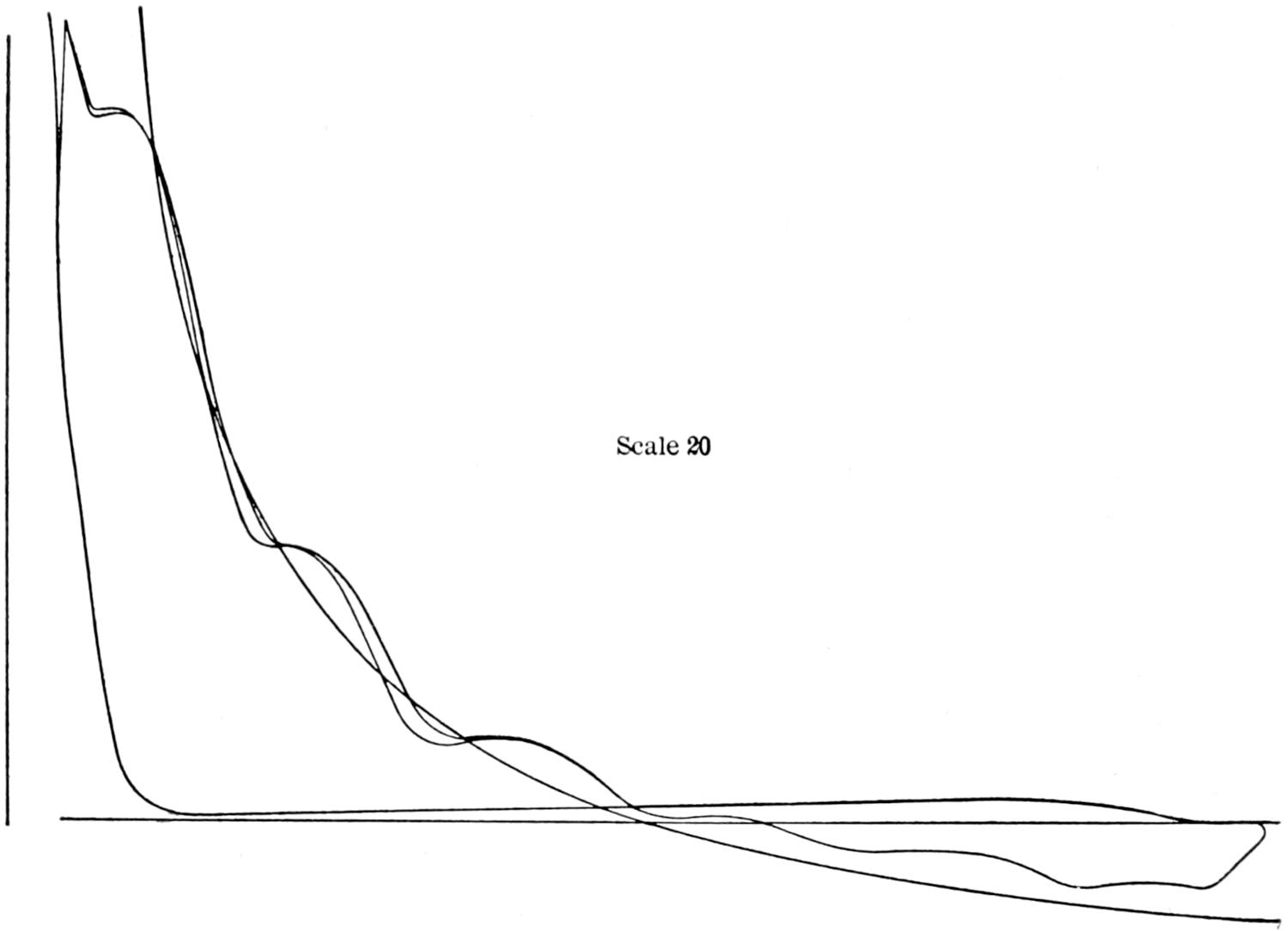

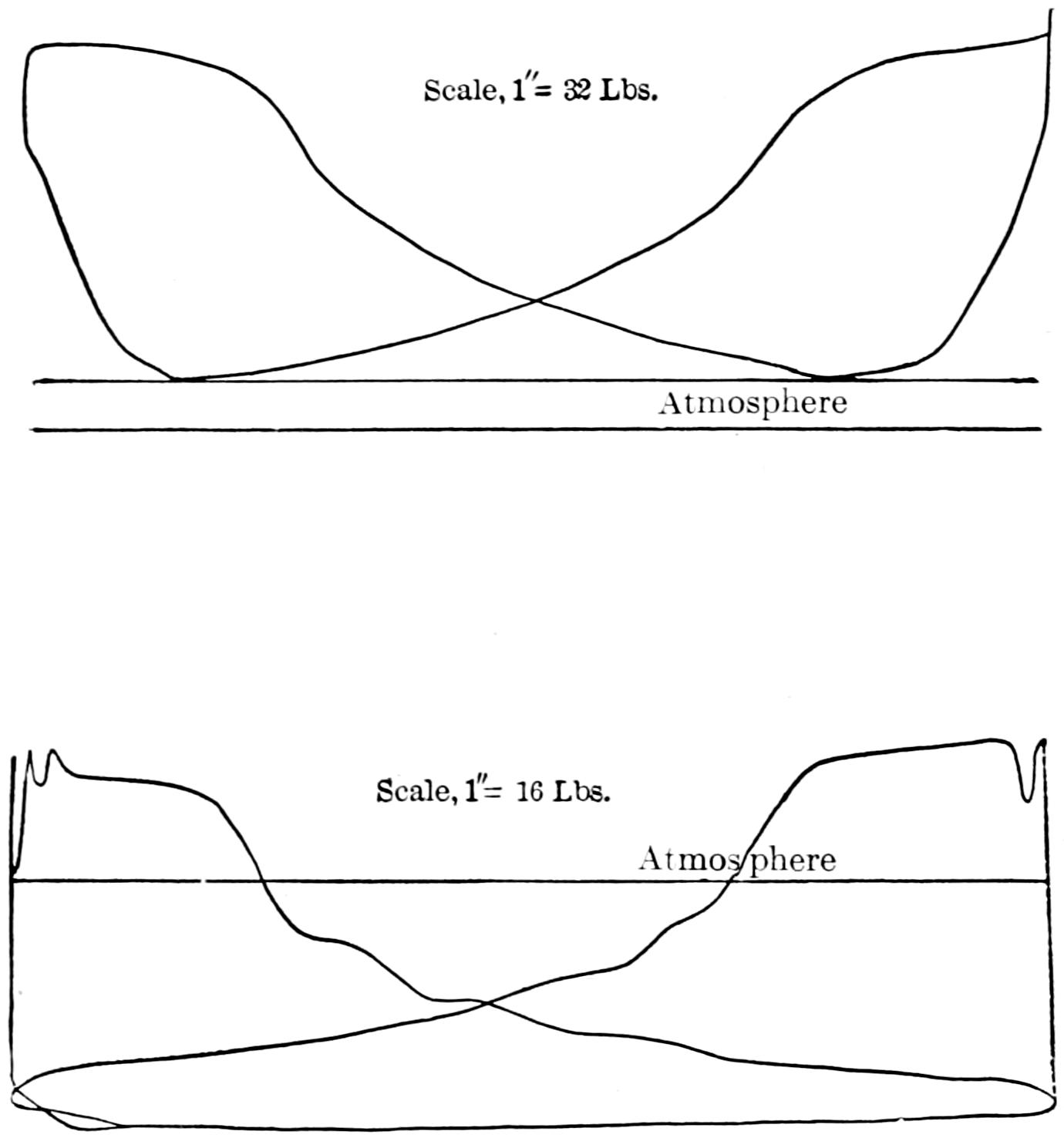

| 10. | Diagram from Allen Engine in London Exhibition of 1862 | 73 |

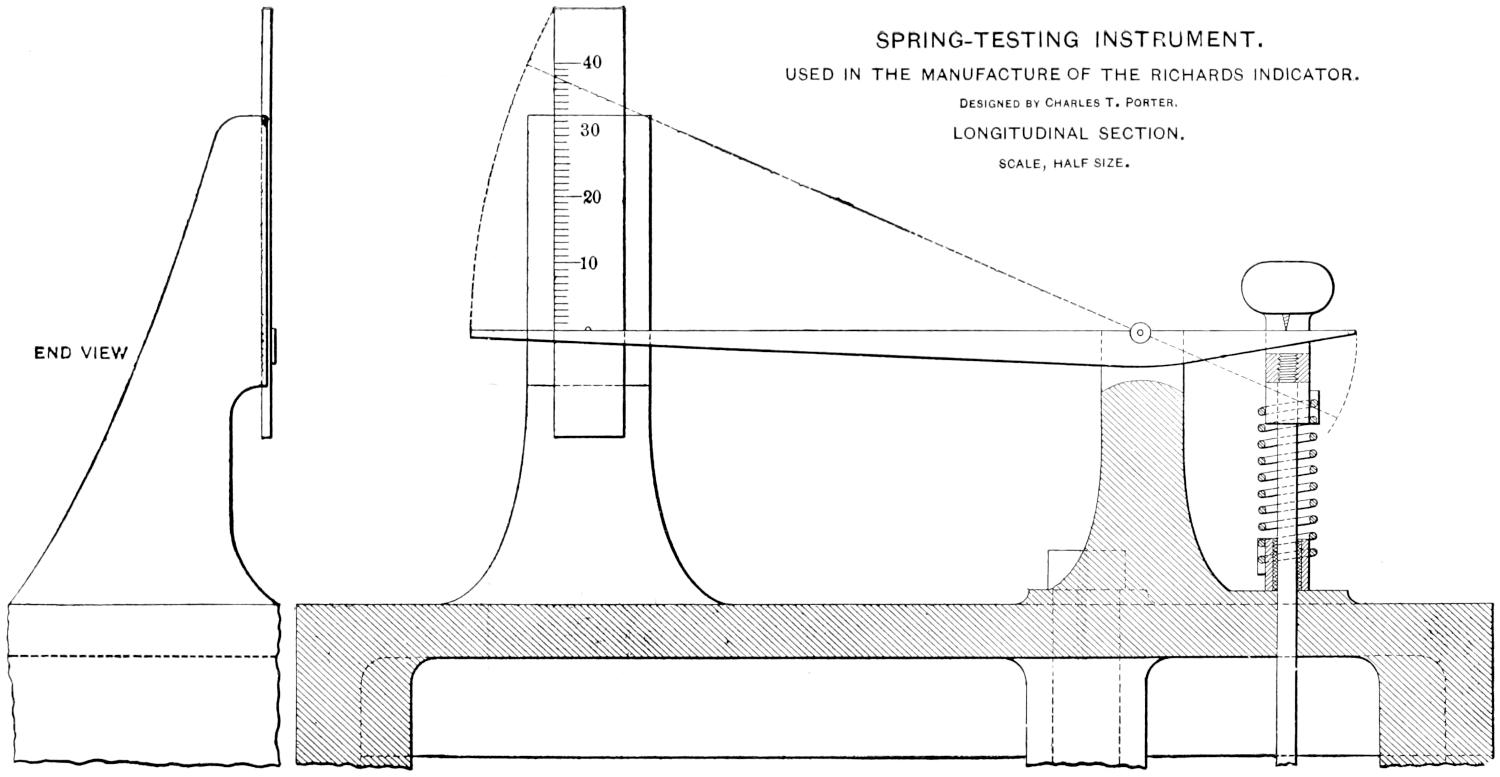

| 11. | Spring-testing Instrument Used in the Manufacture of the Richards Indicator | 86 |

| 12. | Plan of Spring-testing Instrument | 89 |

| 13. | Diagrams from English Locomotives, taken with the Richards Indicator | 91 |

| 14. | Engine Bed Designed by Mr. Porter | 95 |

| 15. | Cross-head Designed by Mr. Porter | 96 |

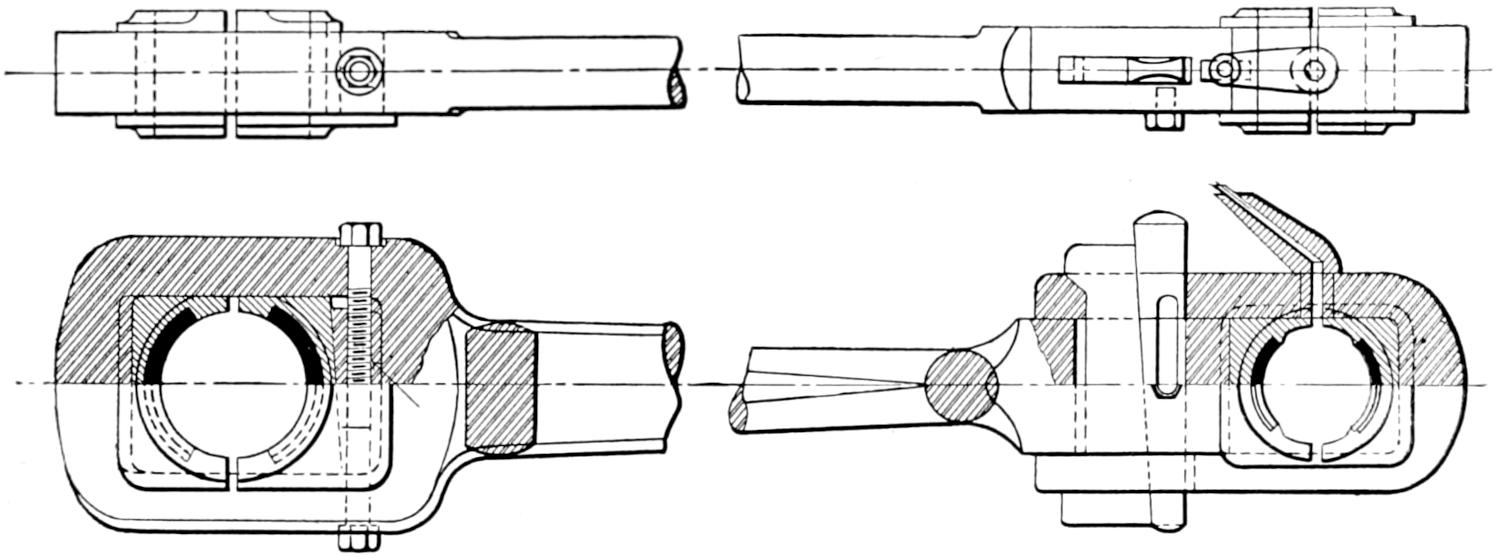

| 16. | Connecting-rod and Strap | 99 |

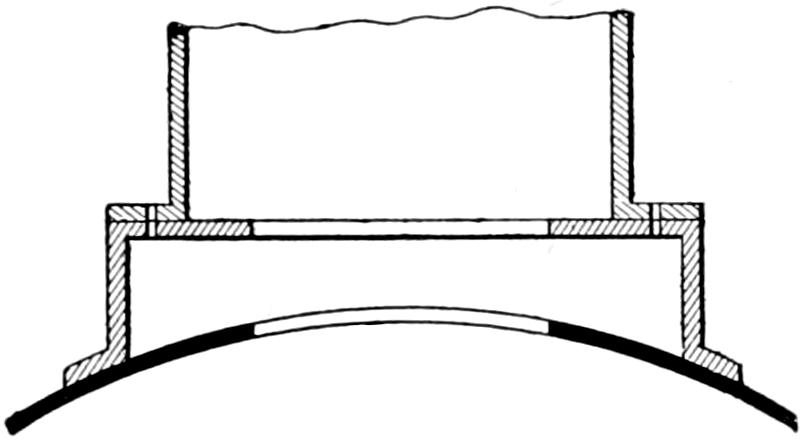

| 17. | Attaching a Steam-drum to a Lancashire Boiler | 107 |

| 18. | Diagrams from Engine of Evan Leigh, Son & Co. | 114 |

| 19. | Condenser and Air-pump Designed by Mr. Porter. (Cross-section) | 118 |

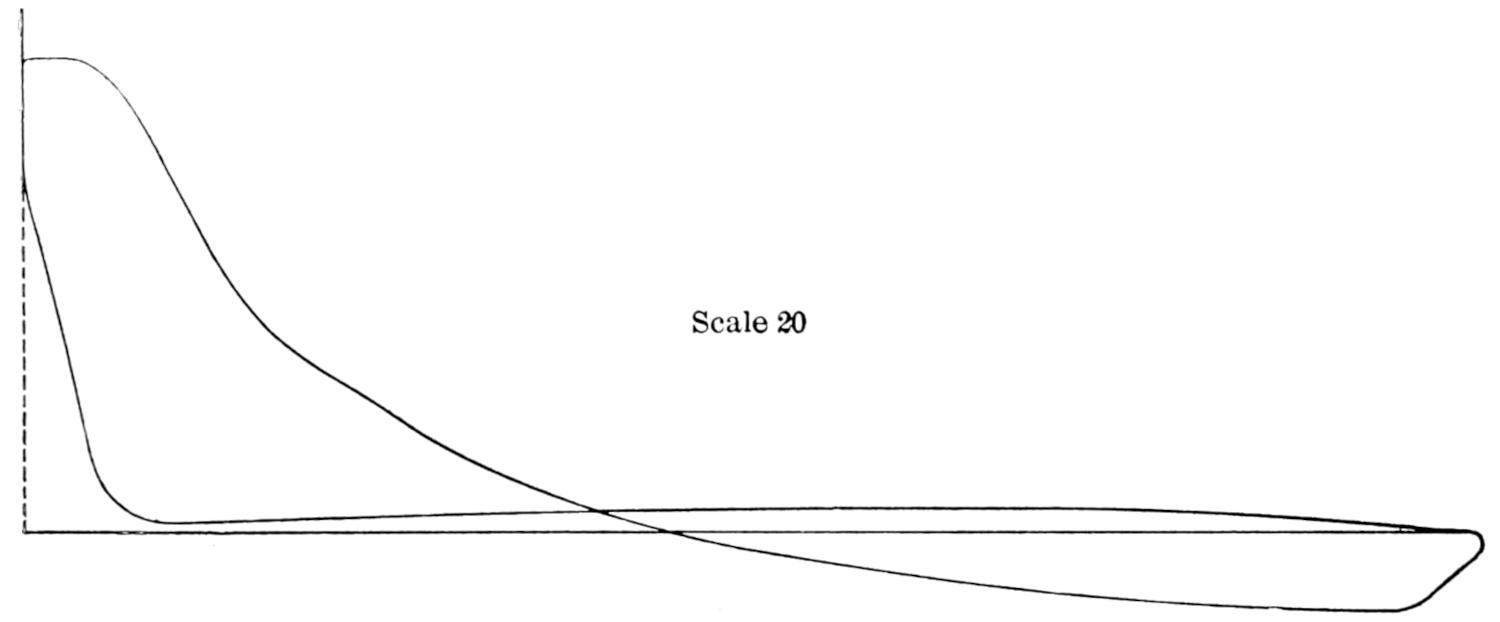

| 20. | Diagrams from Engine Built for Mr. Adams | 138 |

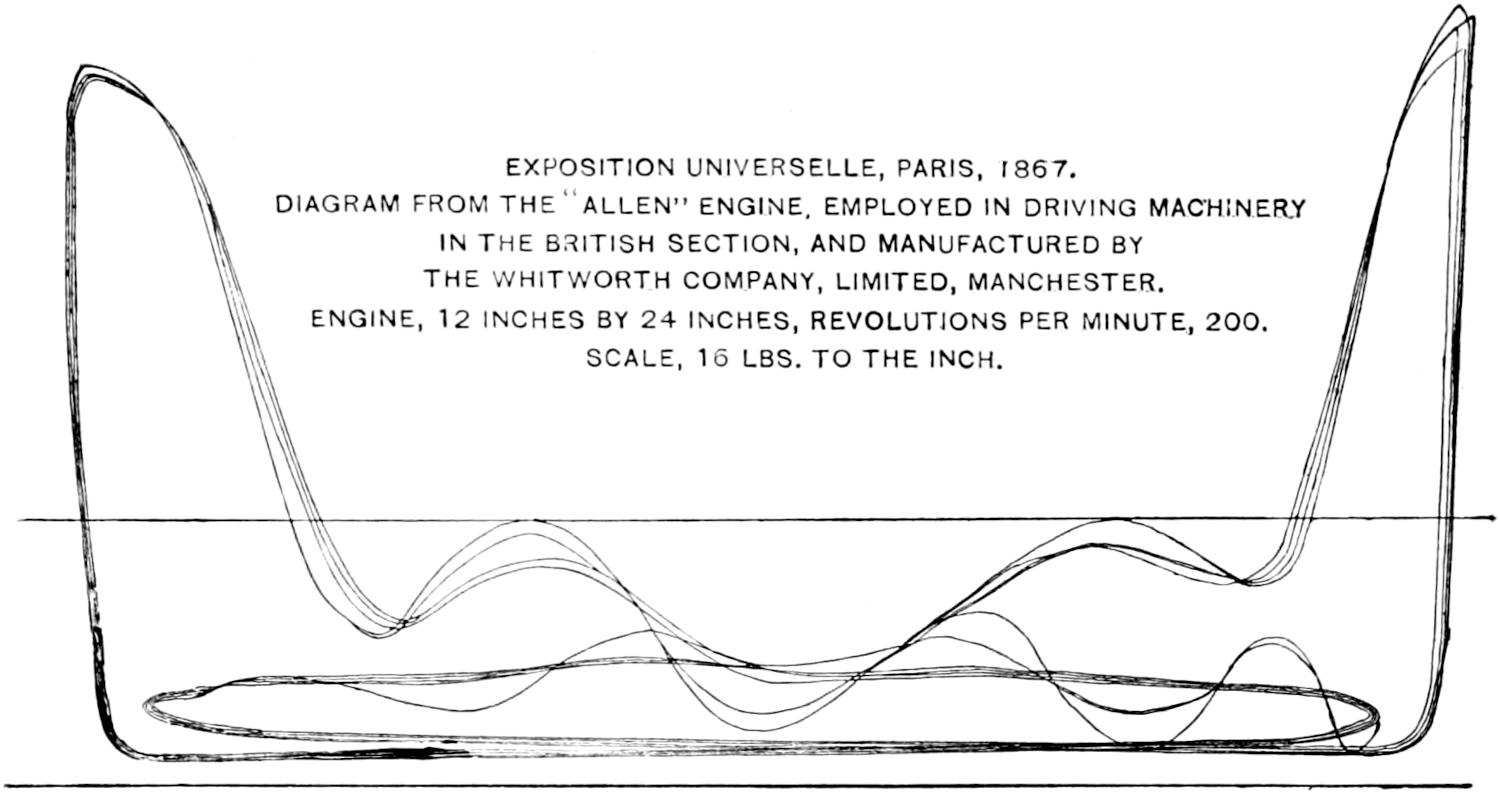

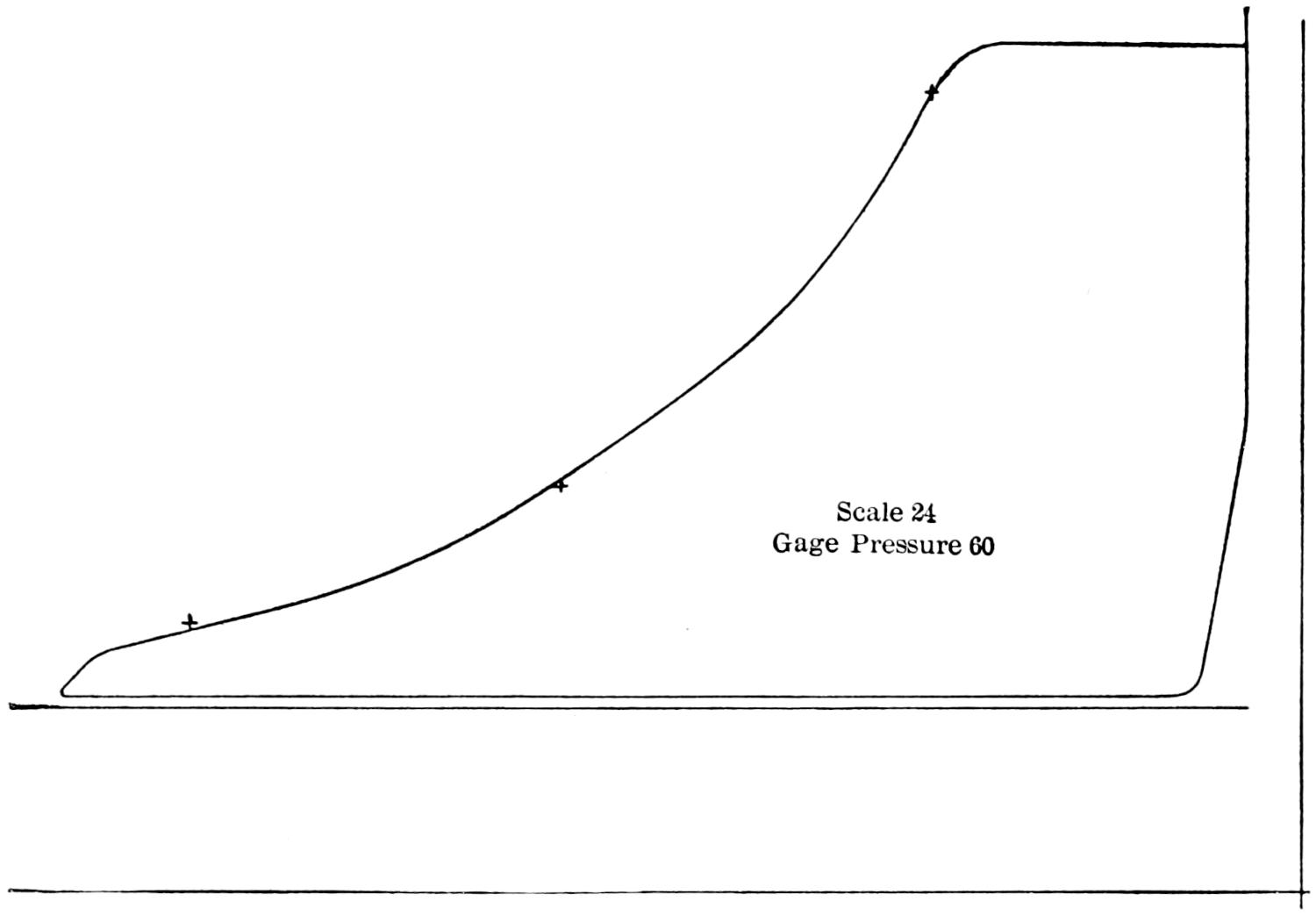

| 21. | Exposition Universelle, Paris, 1867. Diagrams from the “Allen” Engine Employed in Driving Machinery | 142 |

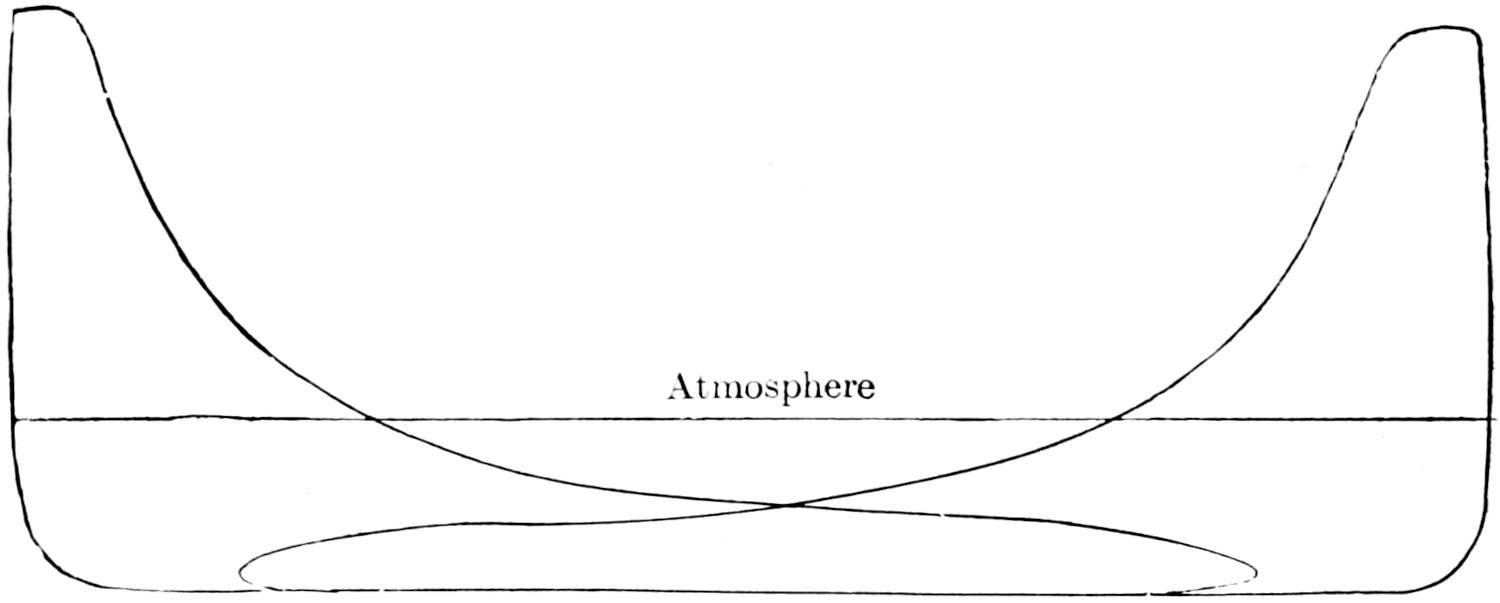

| 22. | Pair of Diagrams from 18×30 Allen Engine at South Tyne Paper Mill, 108 Revolutions, Vacuum 28 Inches. Only Half Intended Load on Engine | 160 |

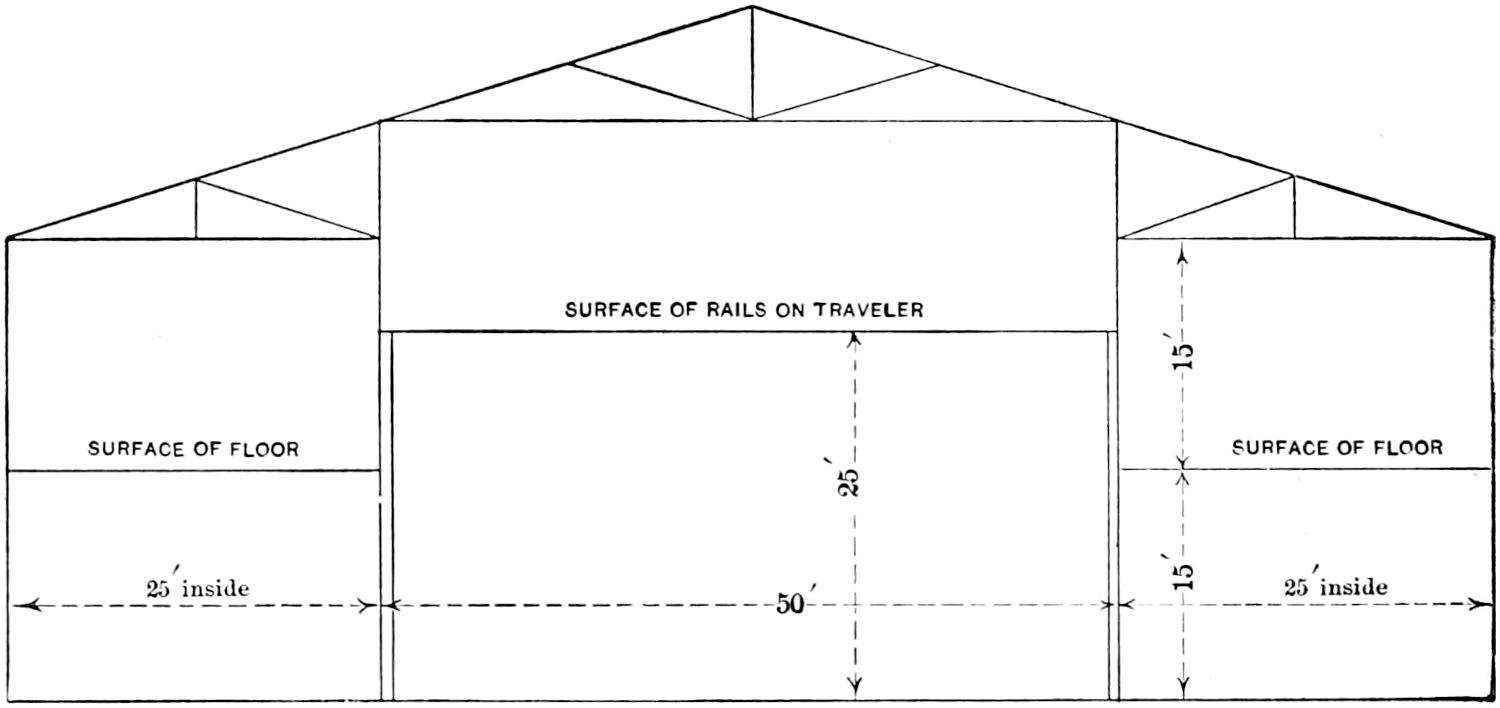

| 23. | Cross-section of Machine Shop Proposed by Mr. Porter in 1868, after the Design of Smith & Coventry | 168 |

| 24. | Card from Allen Engine in Colt’s Armory | 178 |

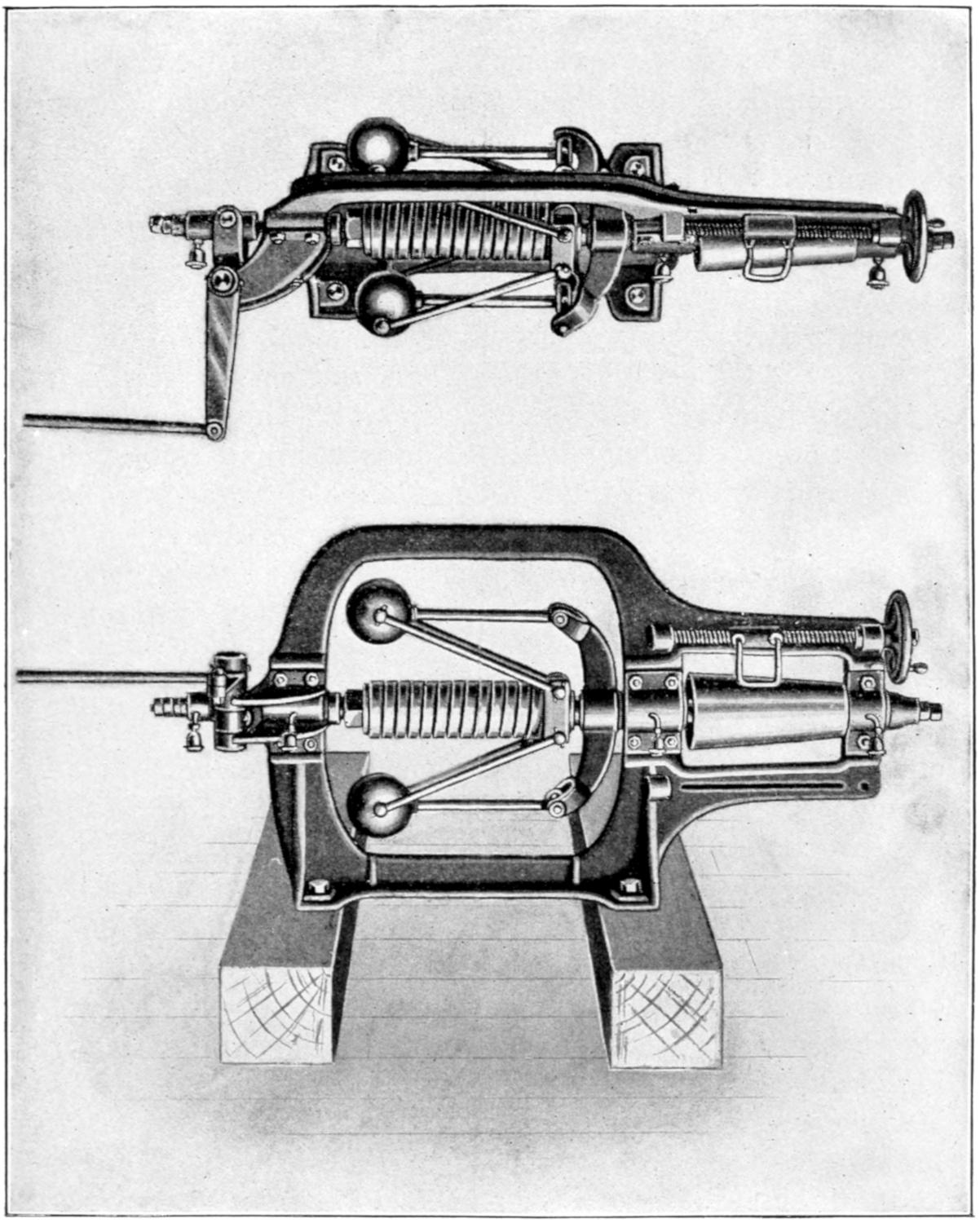

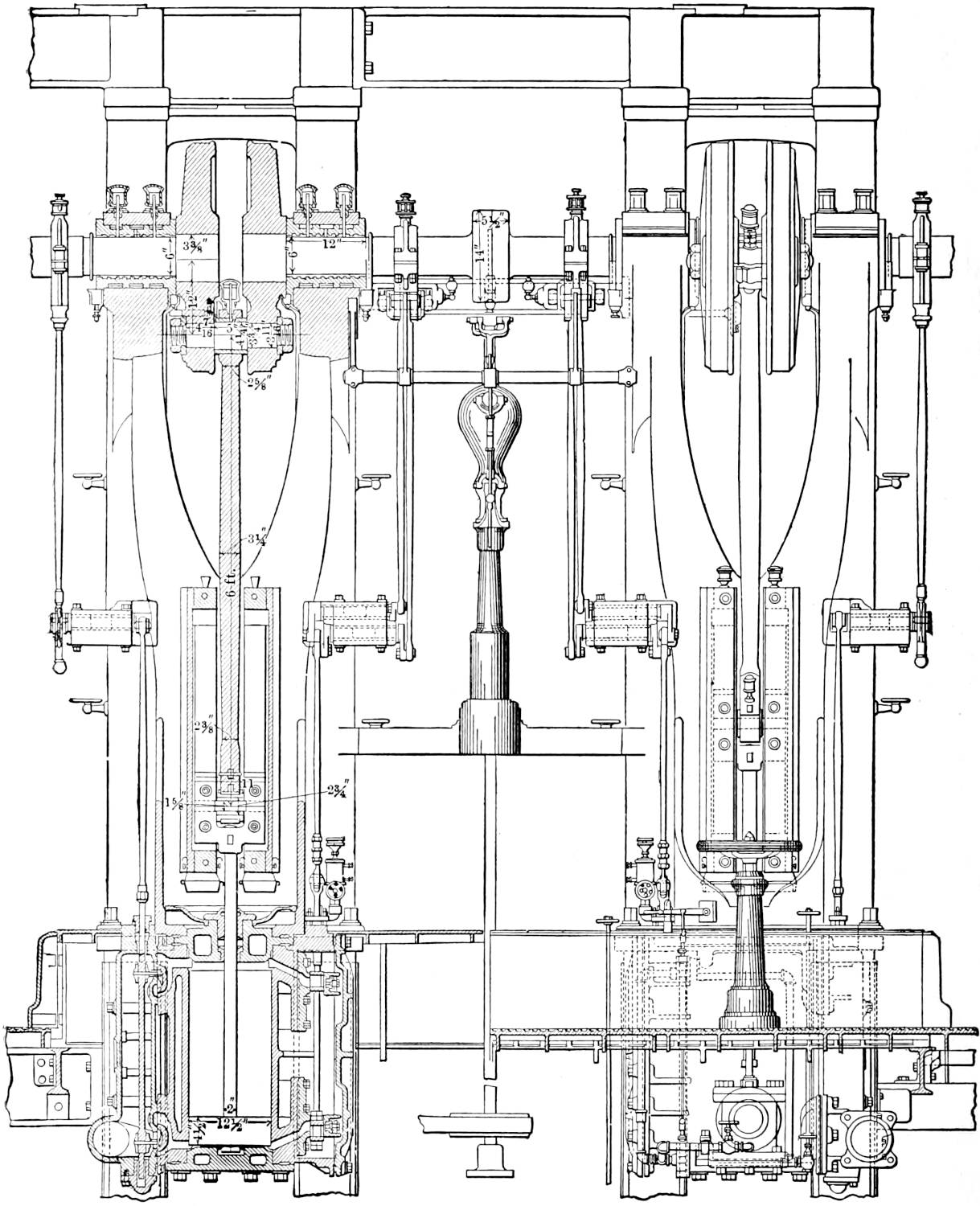

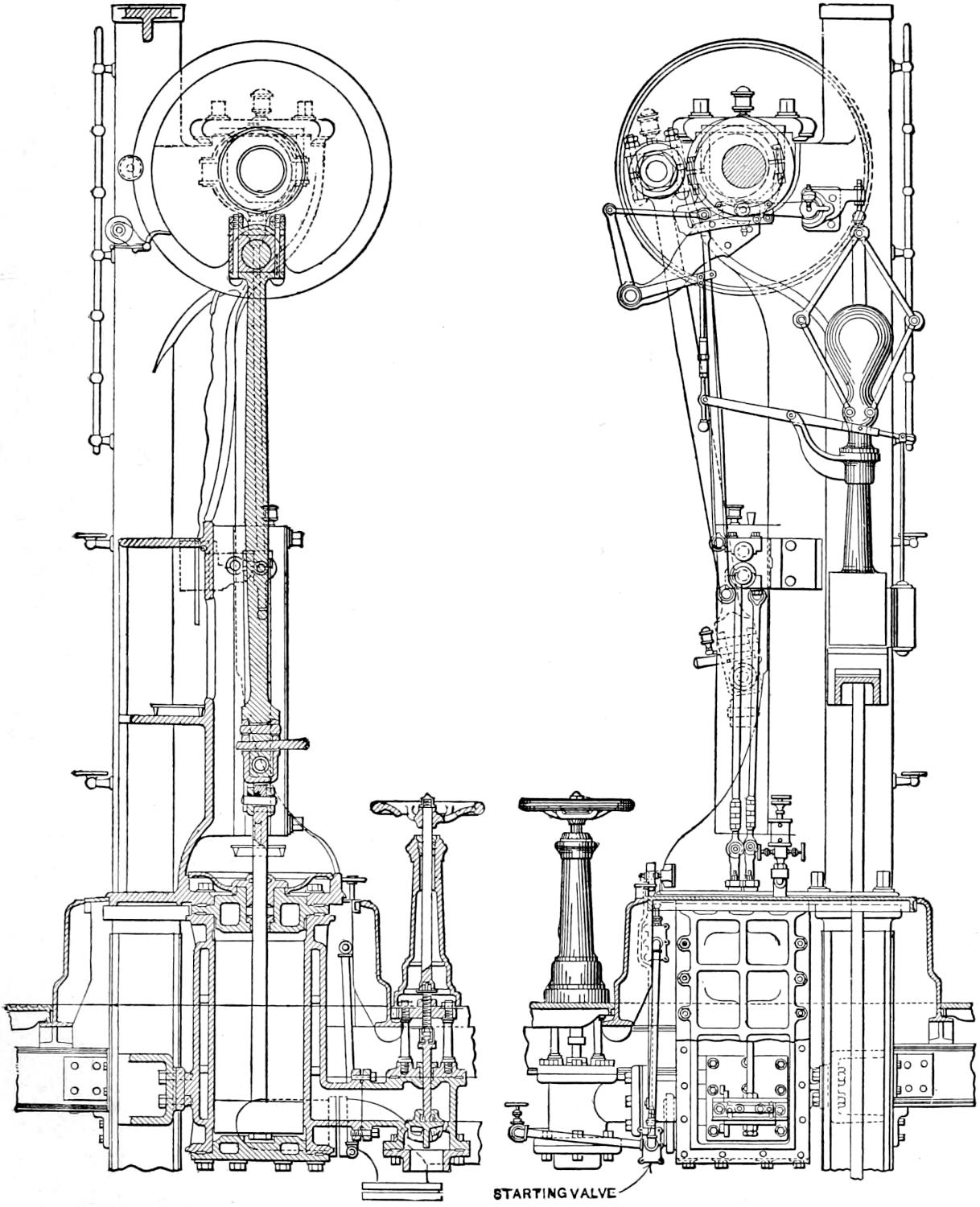

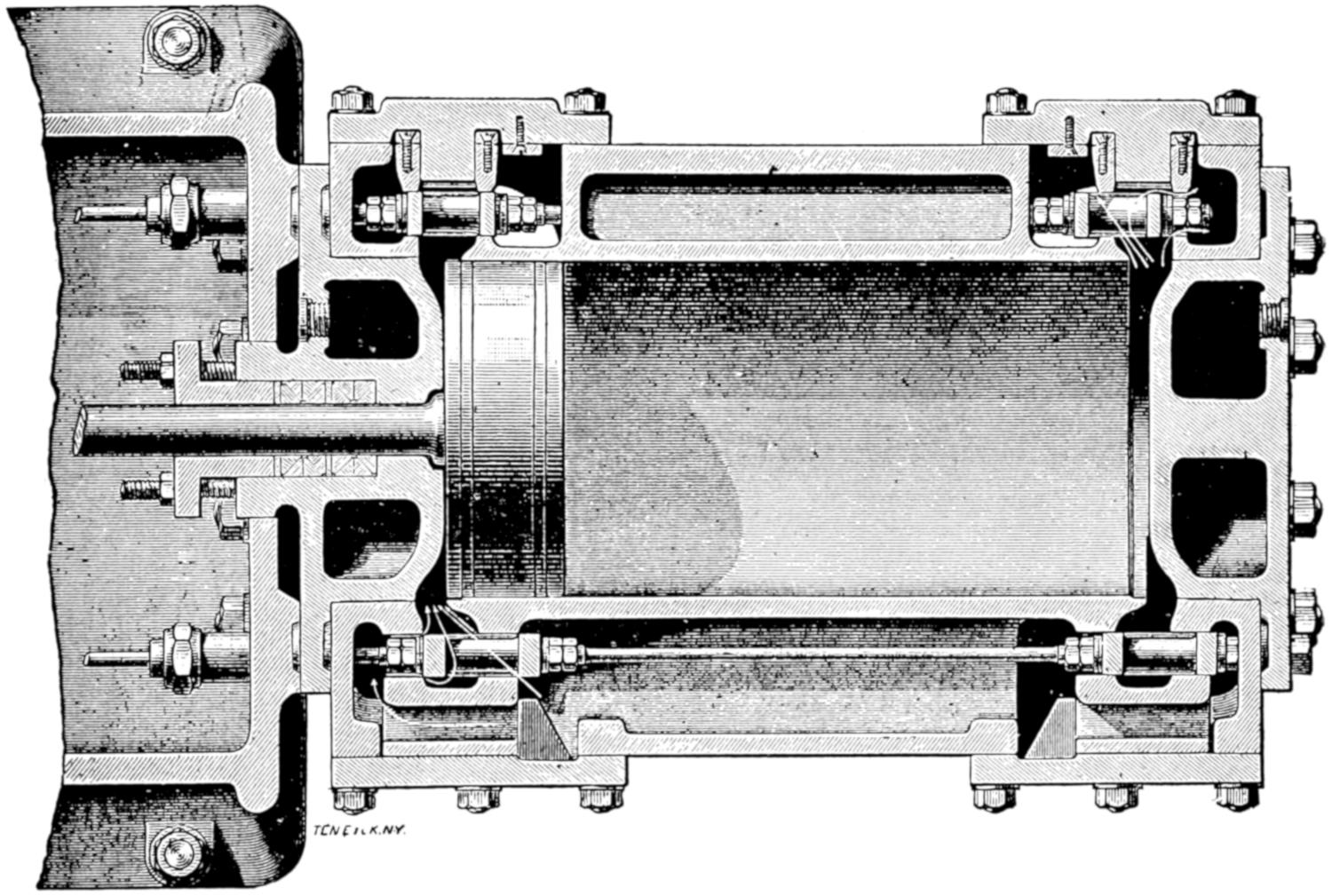

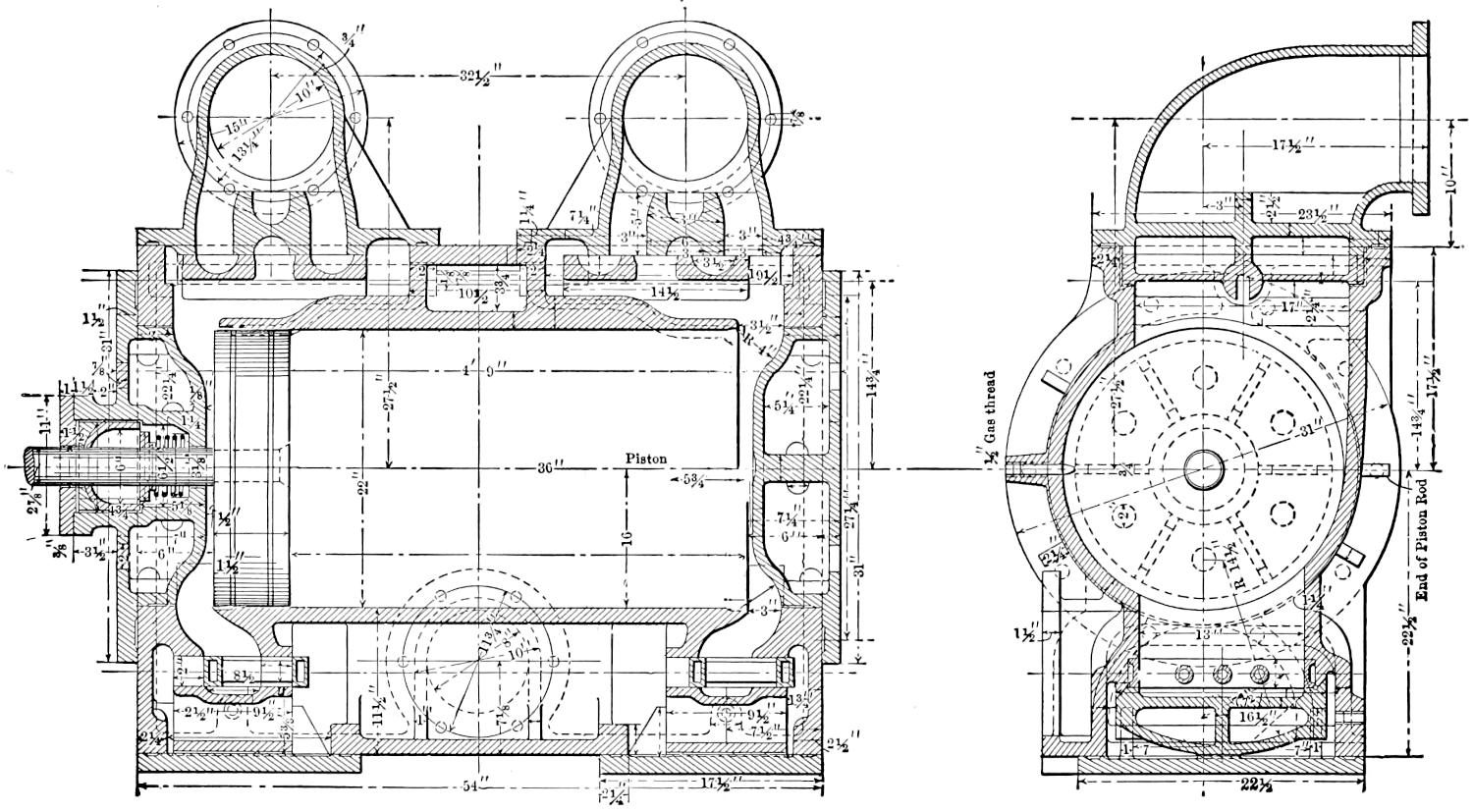

| 25. | Sectional and Front Elevations of One of the Two Pairs of Porter-Allen Engines in the Colt Armory, Hartford, Conn. | 180 |

| 26. | Sectional and Side Elevations of One of the Two Pairs of Porter-Allen Engines in the Colt Armory, Hartford, Conn. | 181 |

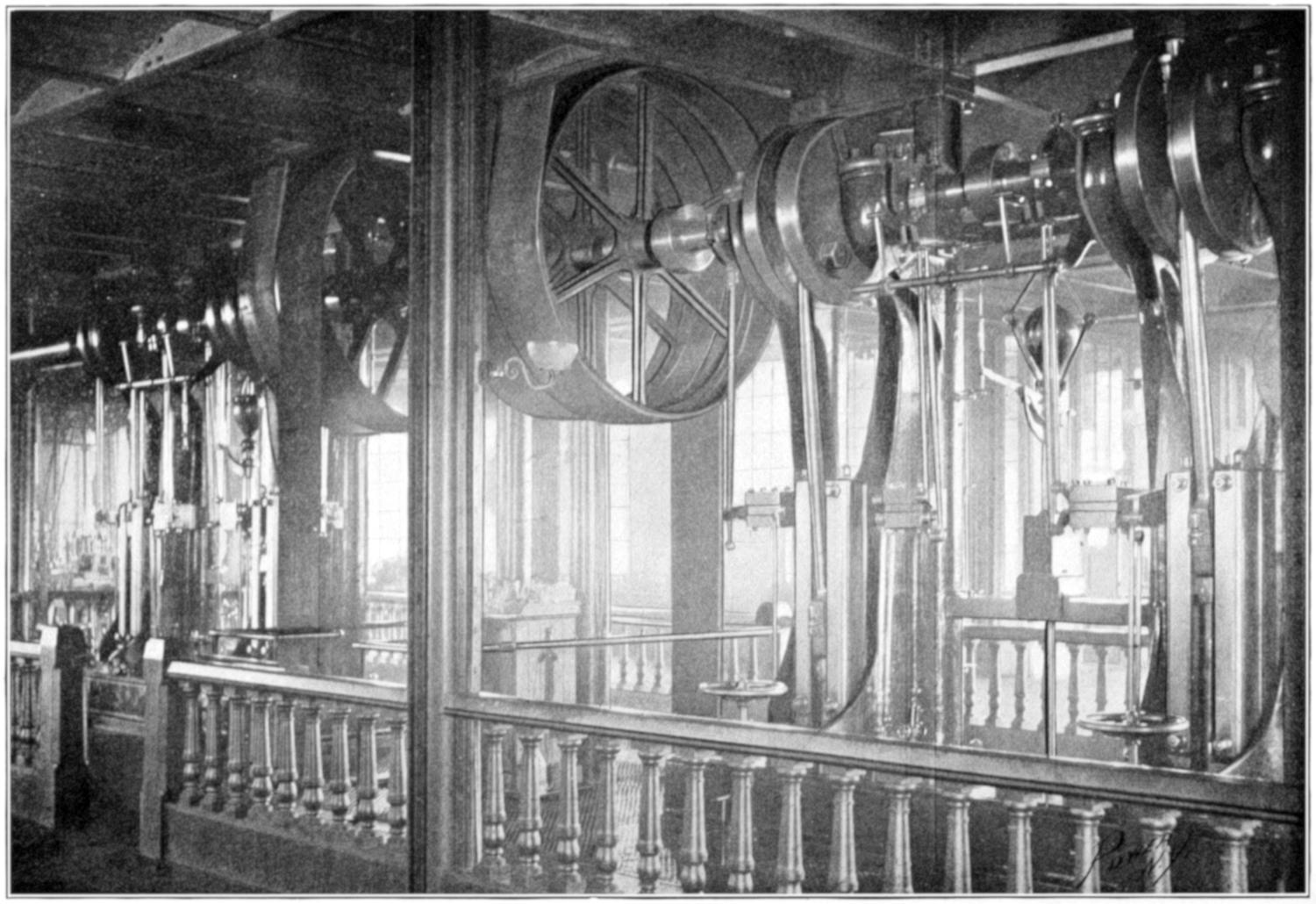

| 27. | Porter-Allen Engines in the Colt Armory, Hartford, Conn. Front View | 181 |

| 28. | Porter-Allen Engines in the Colt Armory, Hartford, Conn. Rear View | 181 |

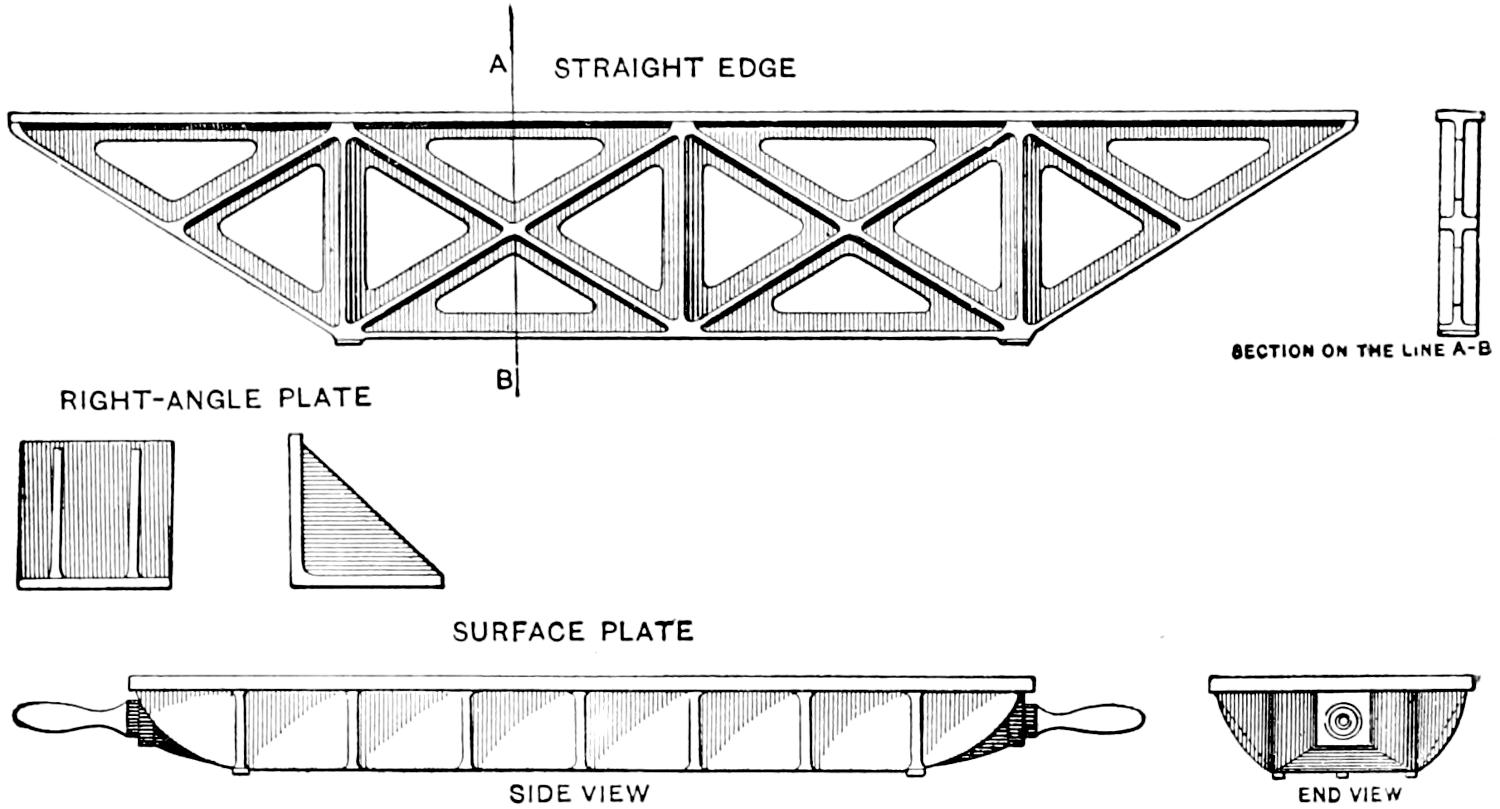

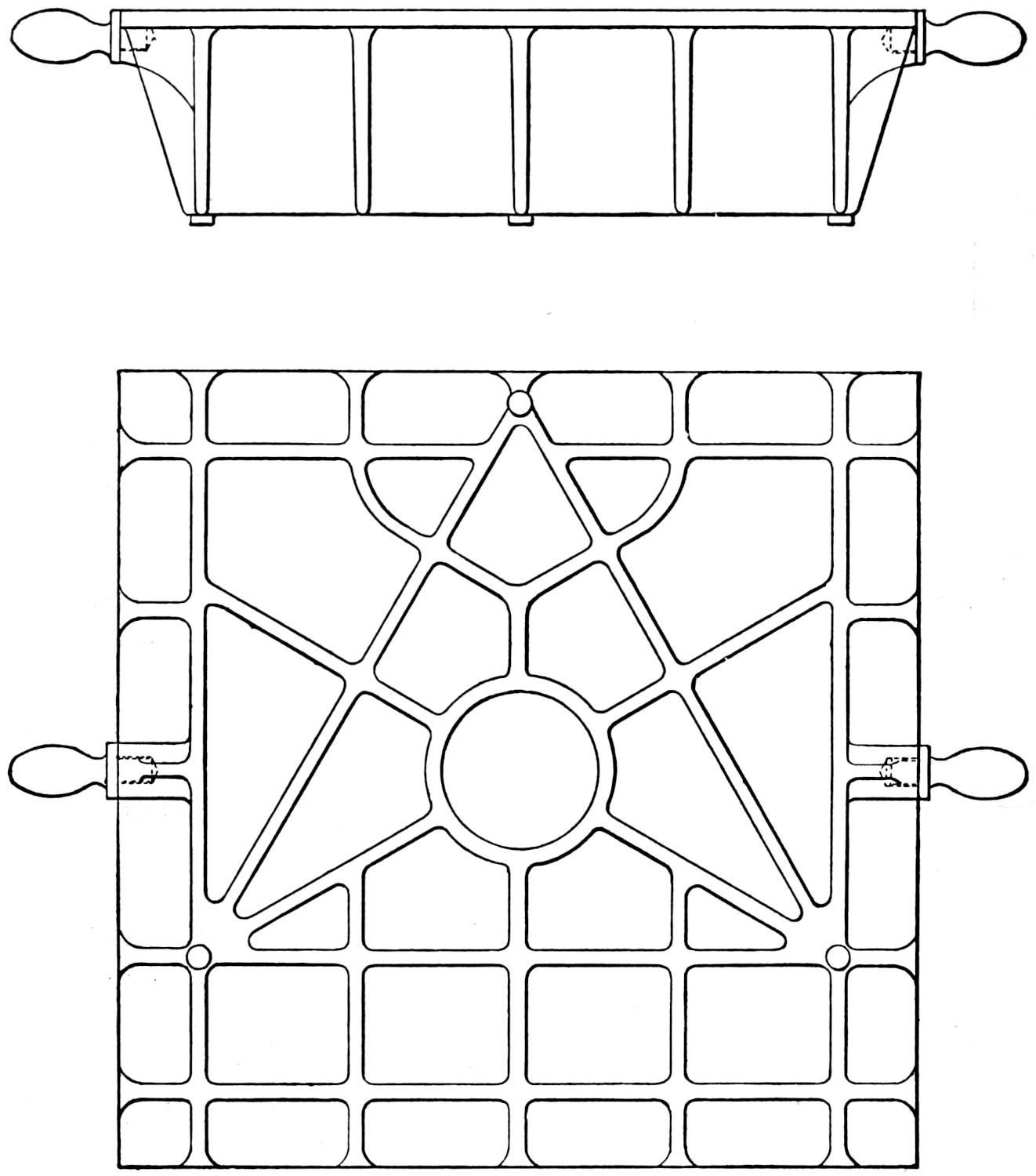

| 29. | Surface Plates Designed by Mr. Porter | 182 |

| 30. | Diagram from Allen Engine, Back End of Cylinder, at Fair of American Institute, 1870 | 194 |

| 31. | Friction Diagram from Allen Engine at Fair of American Institute, 1870[xii] | 196 |

| 32. | Diagram from Allen Engine, Fair of American Institute, 1870, Cutting Off at ¹⁄₄ Stroke | 196 |

| 33. | Apparatus for Graphically Showing the Acceleration and Retardation of the Reciprocating Parts of an Engine | 205 |

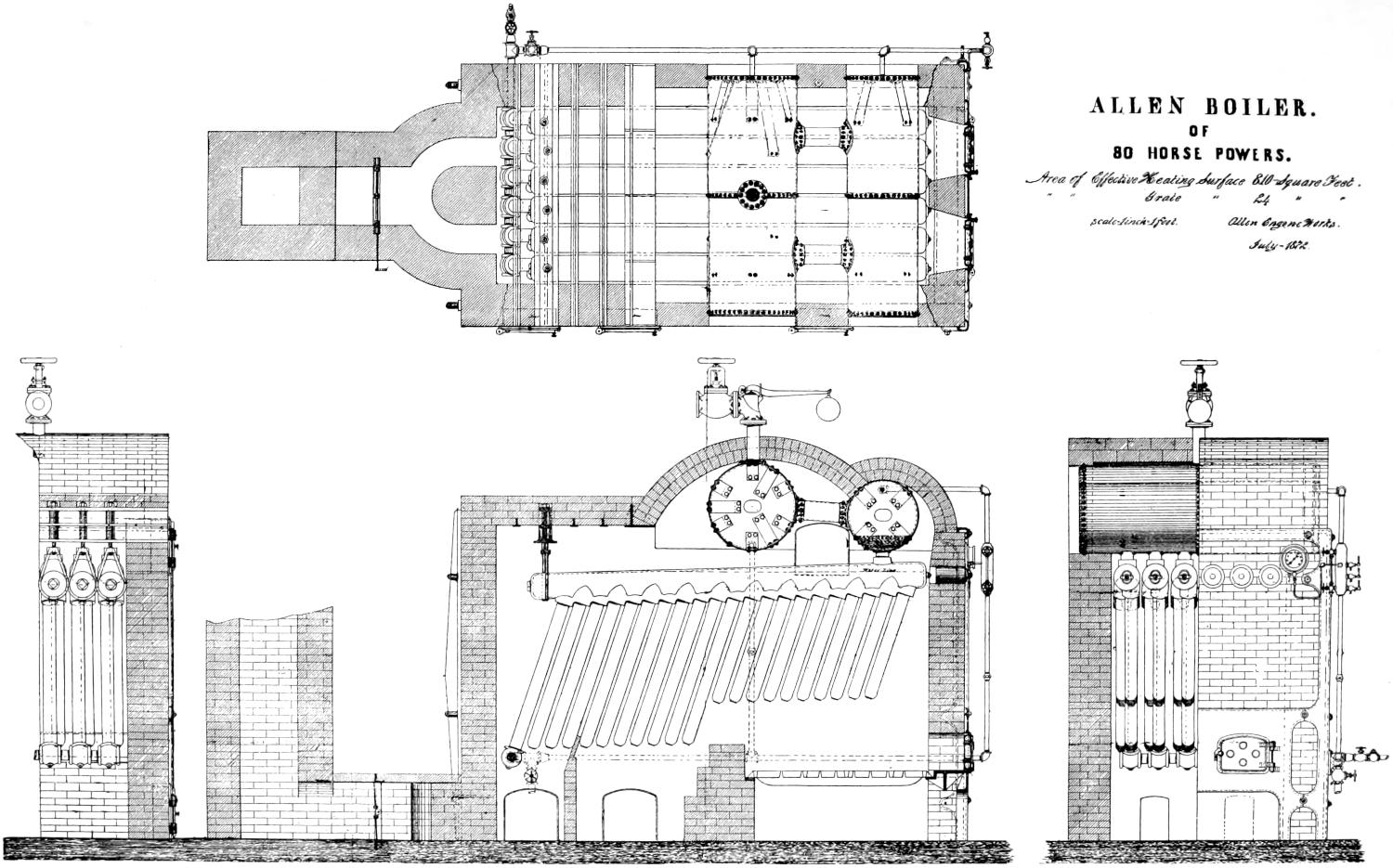

| 34. | The Allen Boiler Facing | 208 |

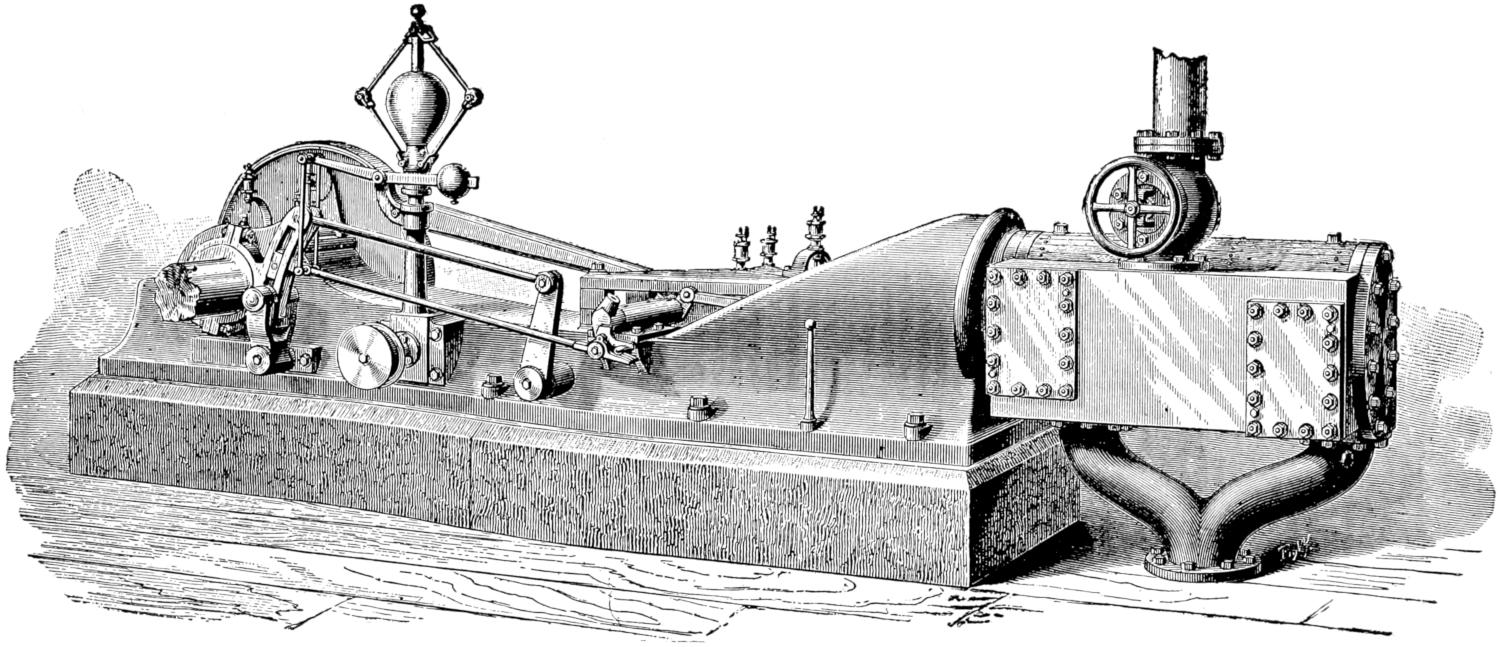

| 35. | The Prototype of the Modern High-speed Engine, Fly-wheel Side | 223 |

| 36. | Prototype of the Modern High-speed Engine, Crank Side | 224 |

| 37. | Longitudinal Section of Cylinder and Valves | 225 |

| 38. | Cross-section of Cylinder and Valves | 226 |

| 39. | Connections of Admission Valves | 226 |

| 40. | First Arrangement of Exhaust Valves | 228 |

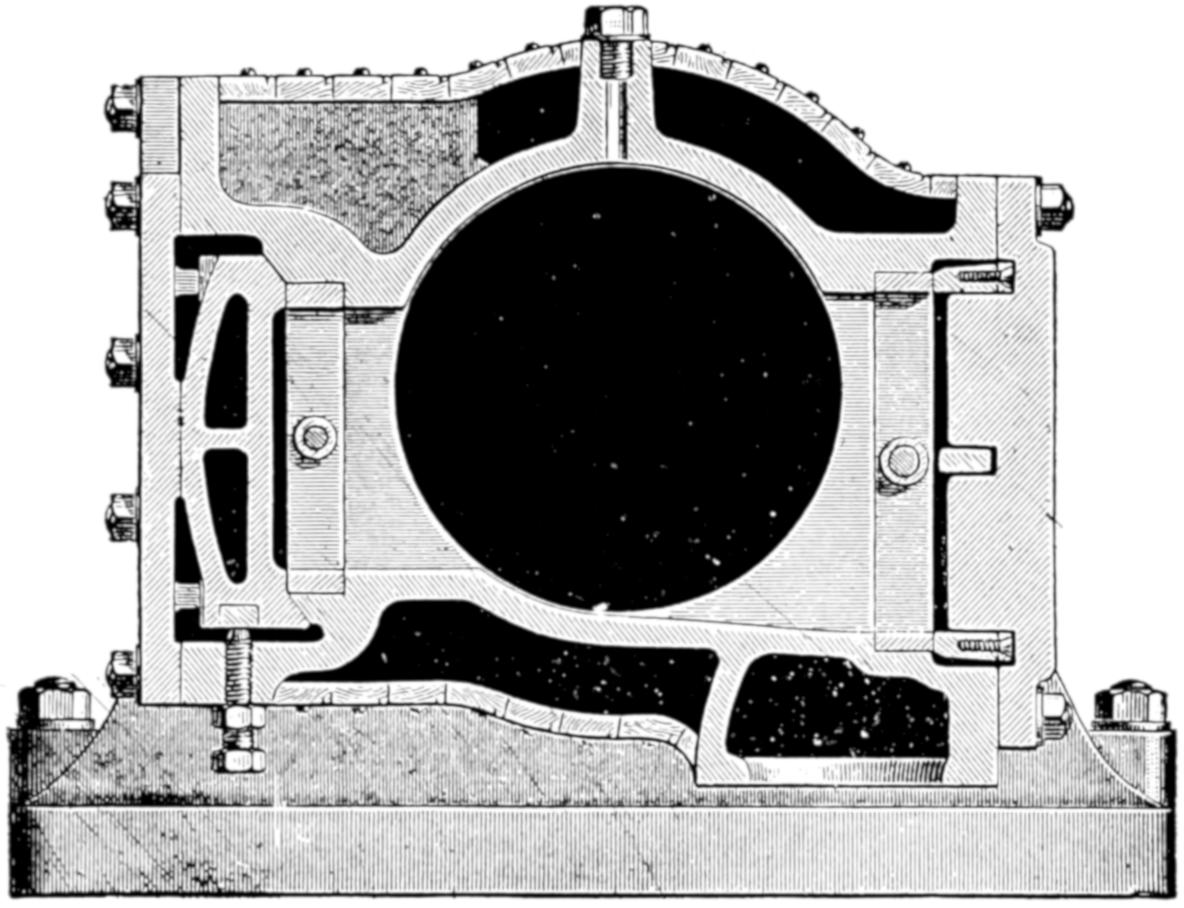

| 41. | Main Bearing | 230 |

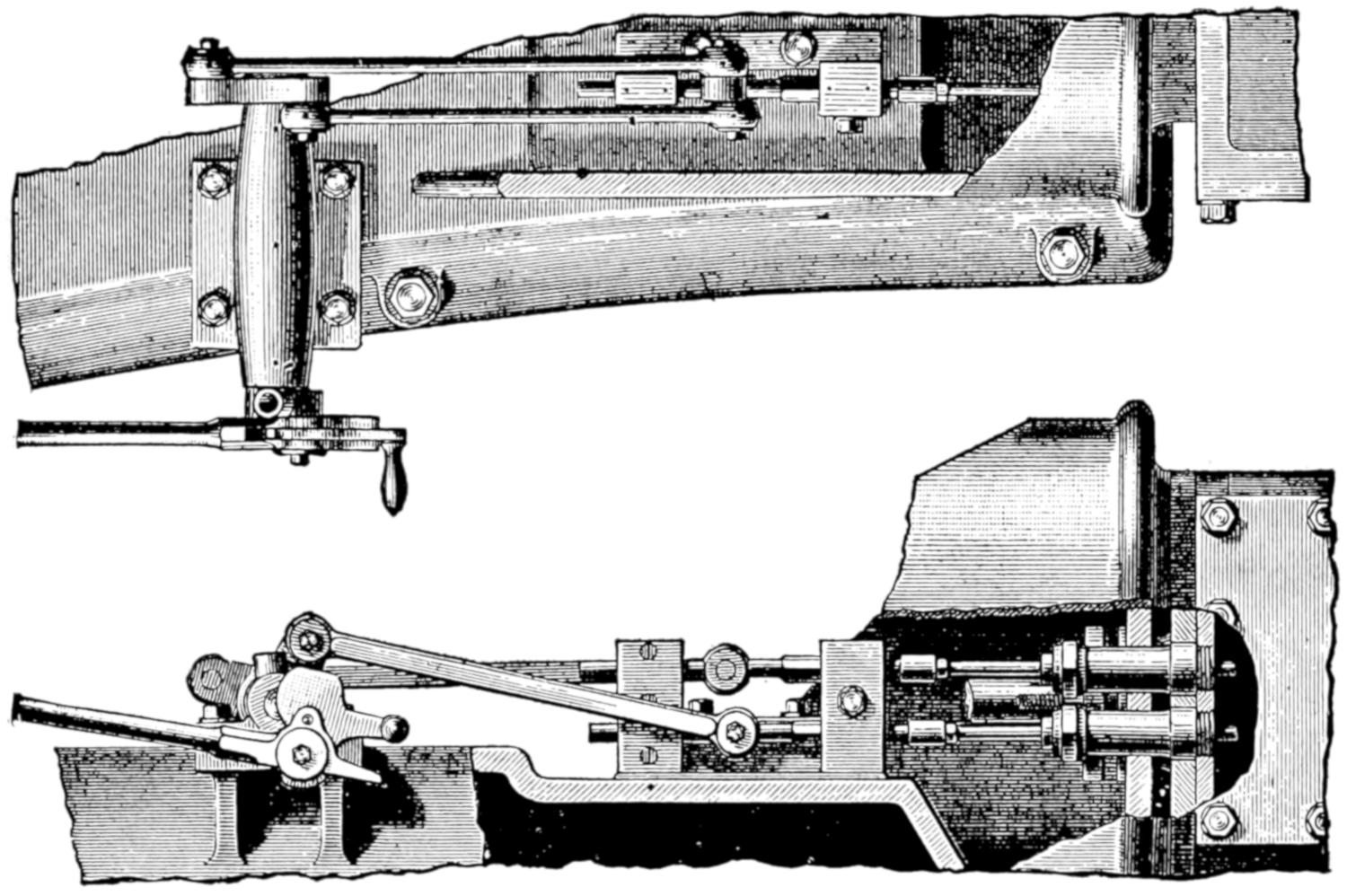

| 42. | Eccentric and Cross-head and Crank-pin Lubricators | 230 |

| 43. | Surface Plate for Producing a True Plane | 234 |

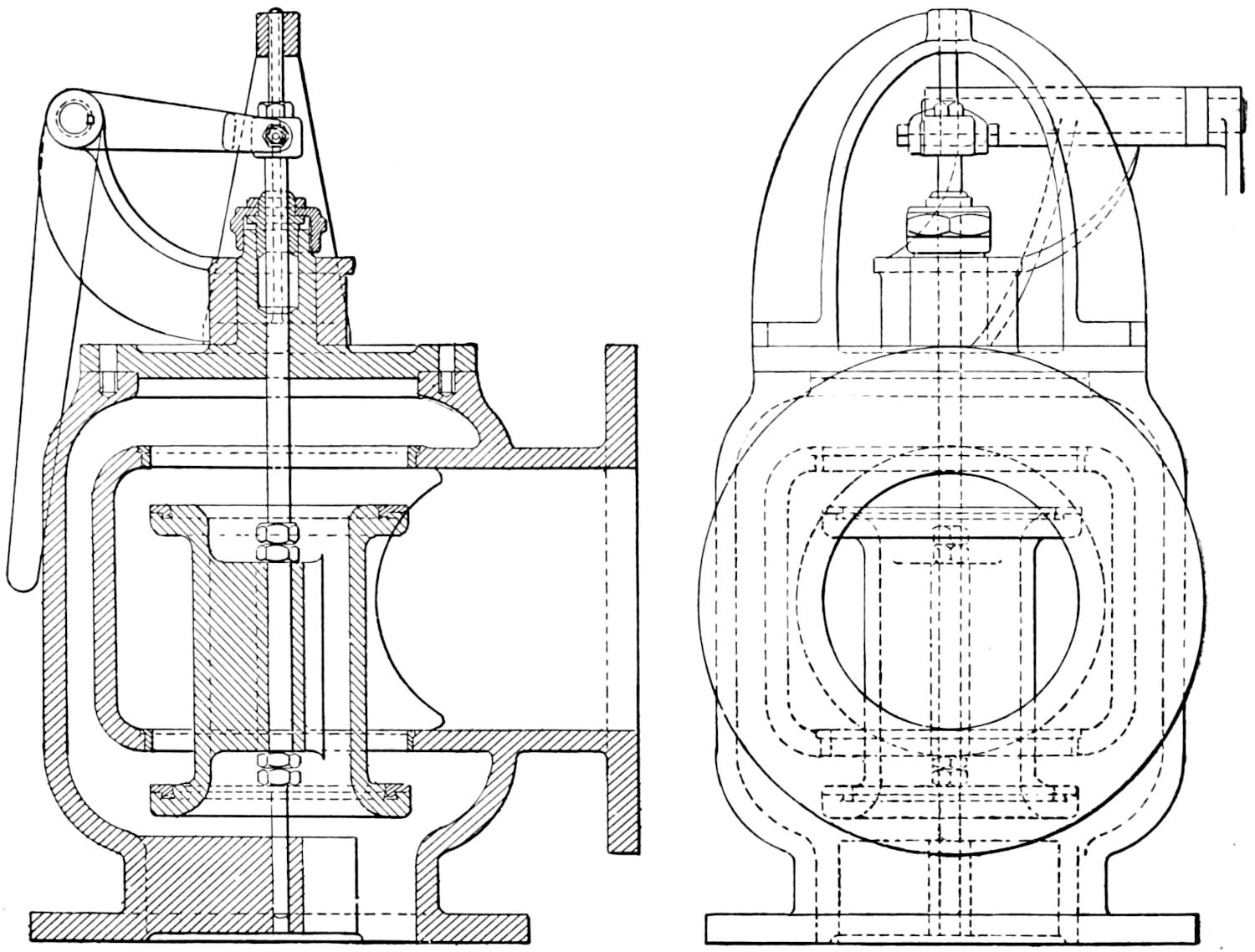

| 44. | Mr. Porter’s Regulating Valve | 244 |

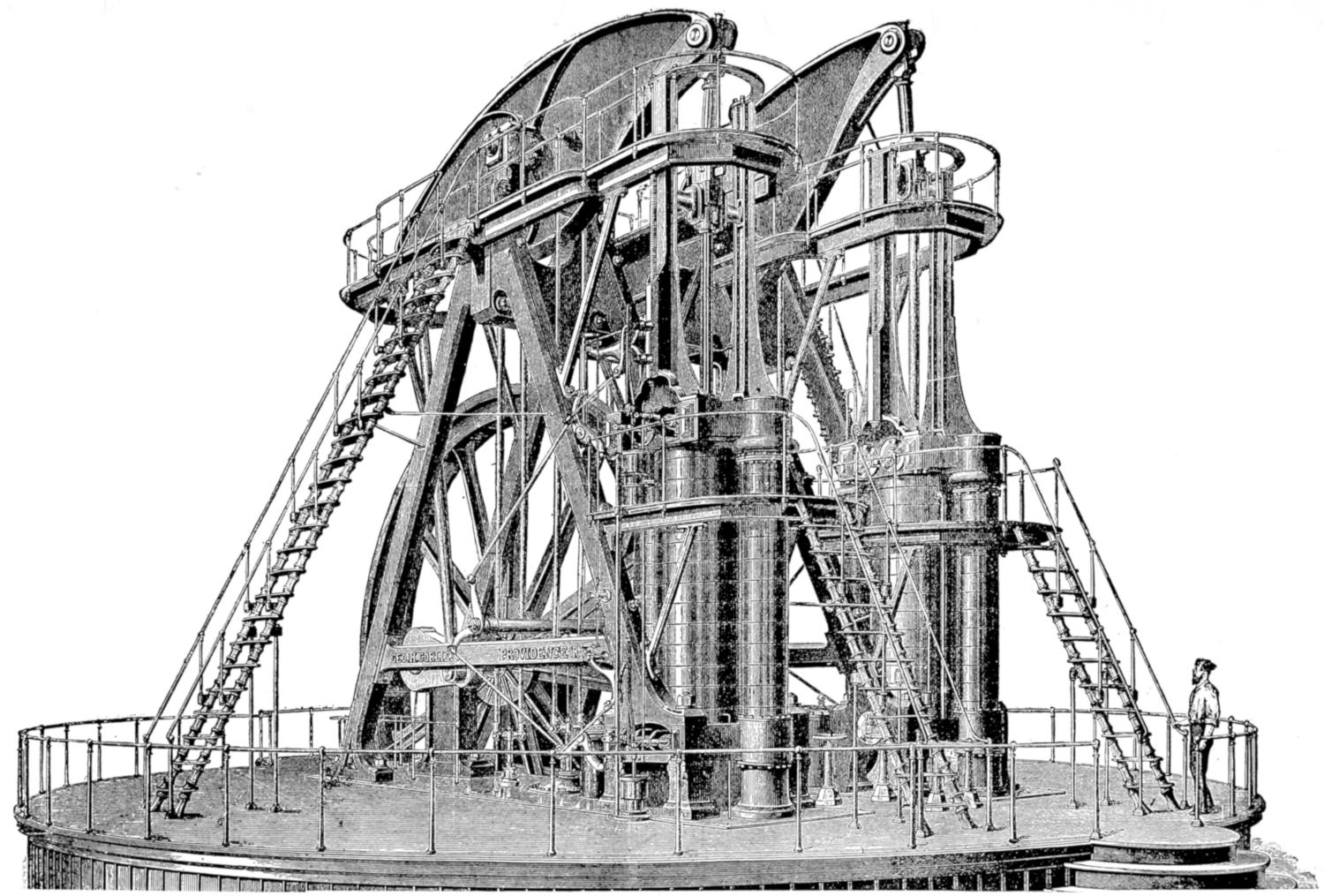

| 45. | The Corliss Engine Exhibited at the Centennial Exhibition | 249 |

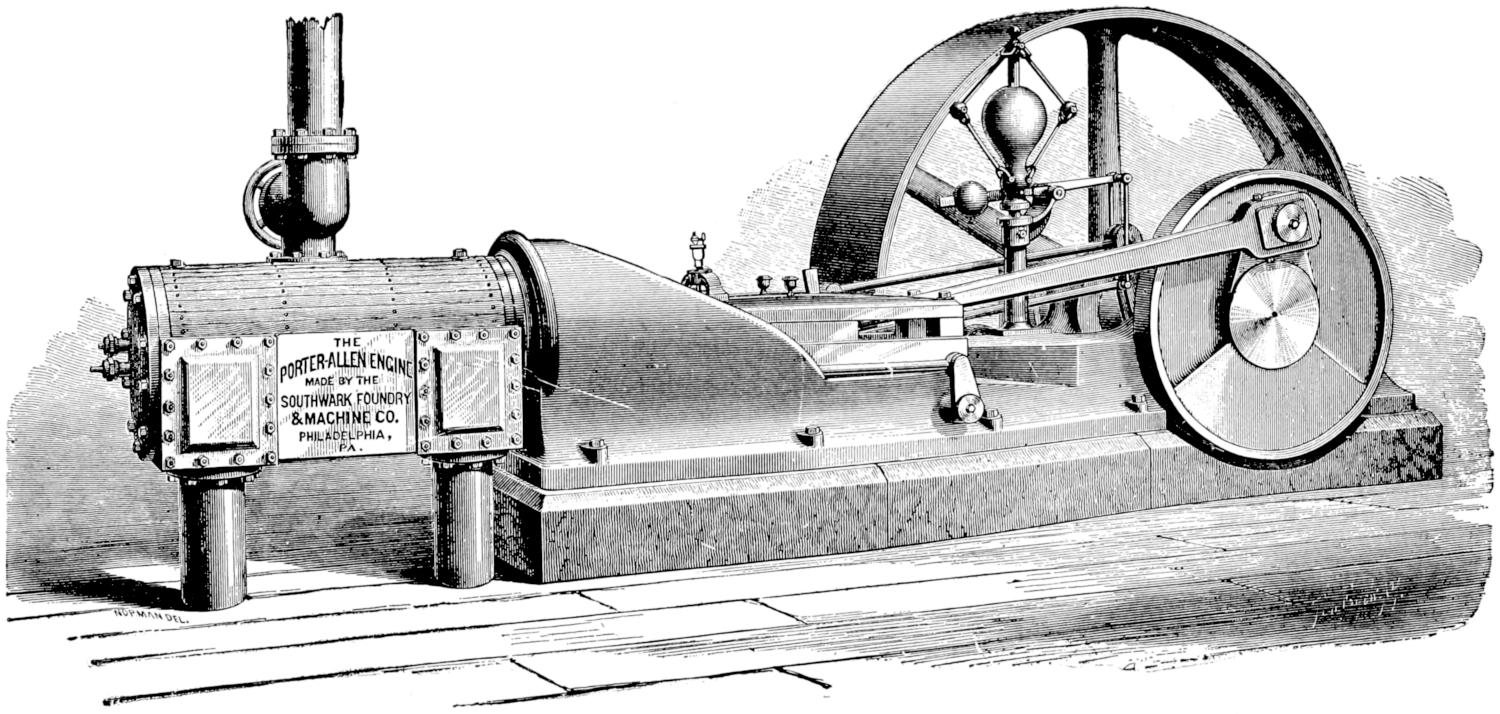

| 46. | Porter-Allen Engine Equal in Power to the Exhibited Corliss Engine | 250 |

| 47. | Mr. Porter’s Fly-wheel | 269 |

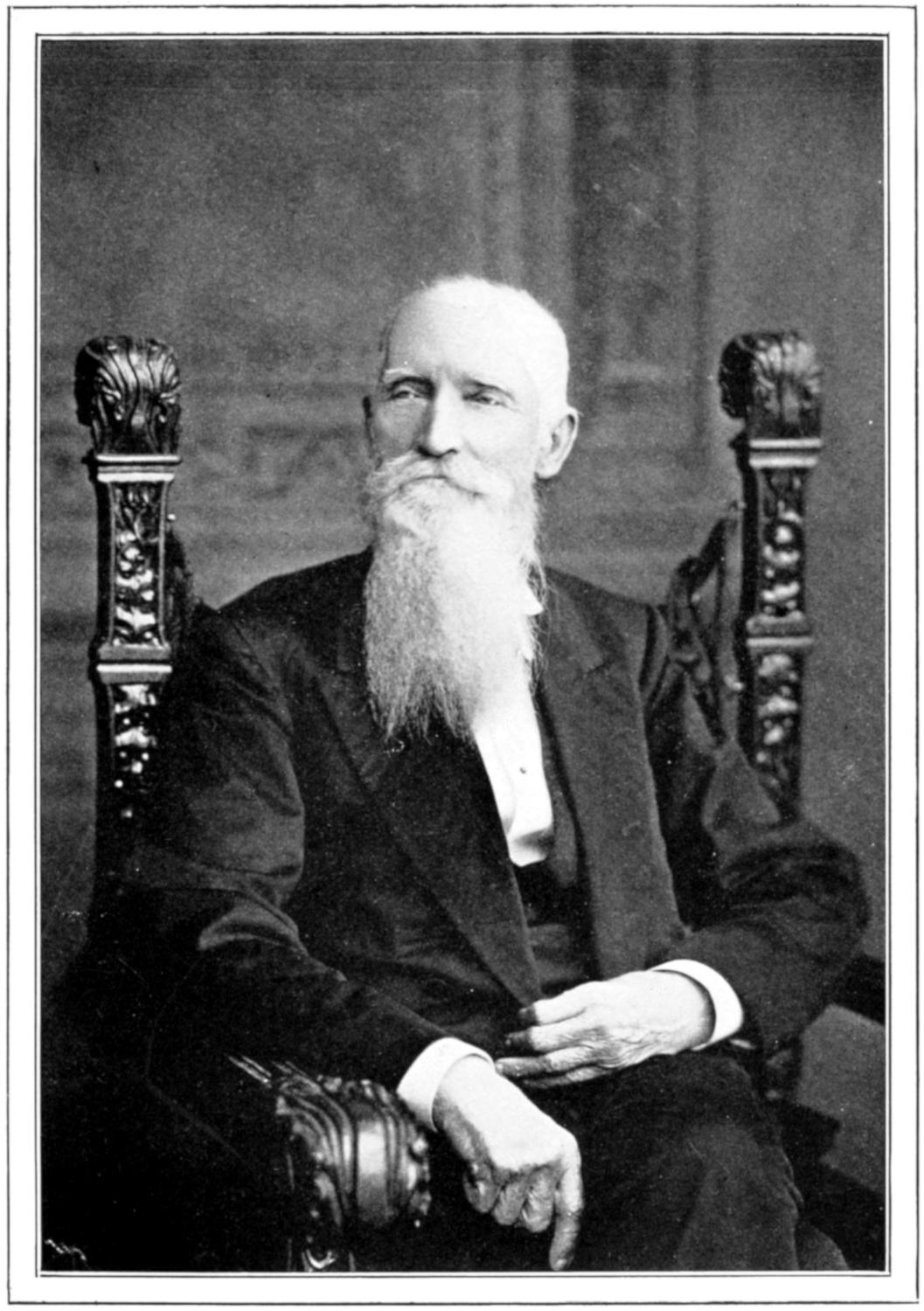

| 48. | Connection of Arms and Rim in Mr. Fritz’ Fly-wheel | 273 |

| 49. | Mr. Allen’s Patent Pressure Plate | 293 |

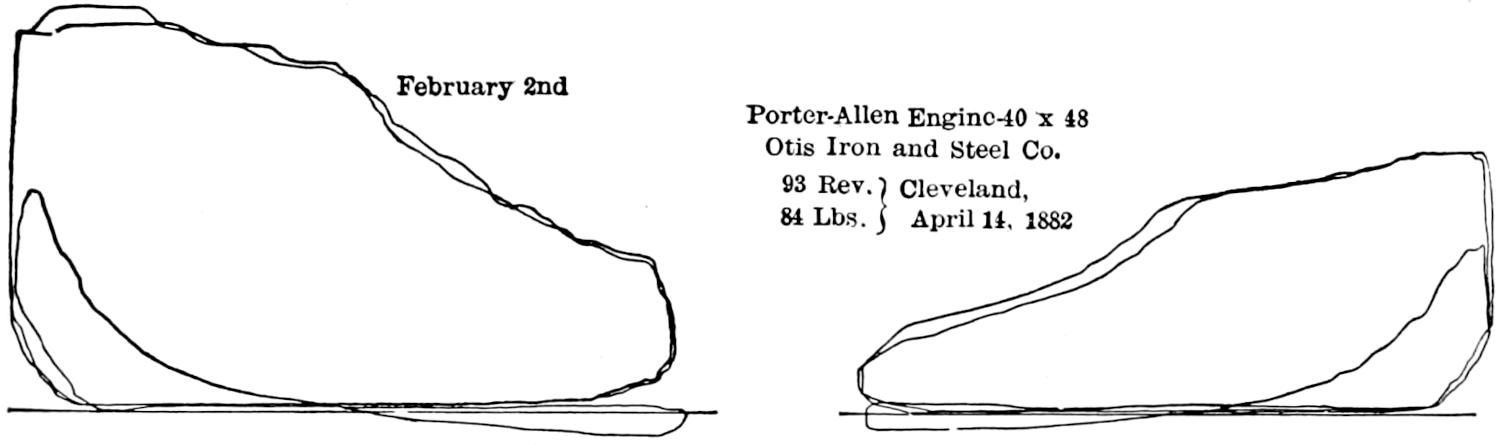

| 50. | Diagrams from the Otis Engine | 311 |

| 51. | Otis Engine. Dash Pot for Governor | 313 |

| 52. | Diagrams from my First and Only Compound Engine | 318 |

[xiii]

LIST OF FULL-PAGE HALF-TONE PORTRAITS

| PAGE | ||

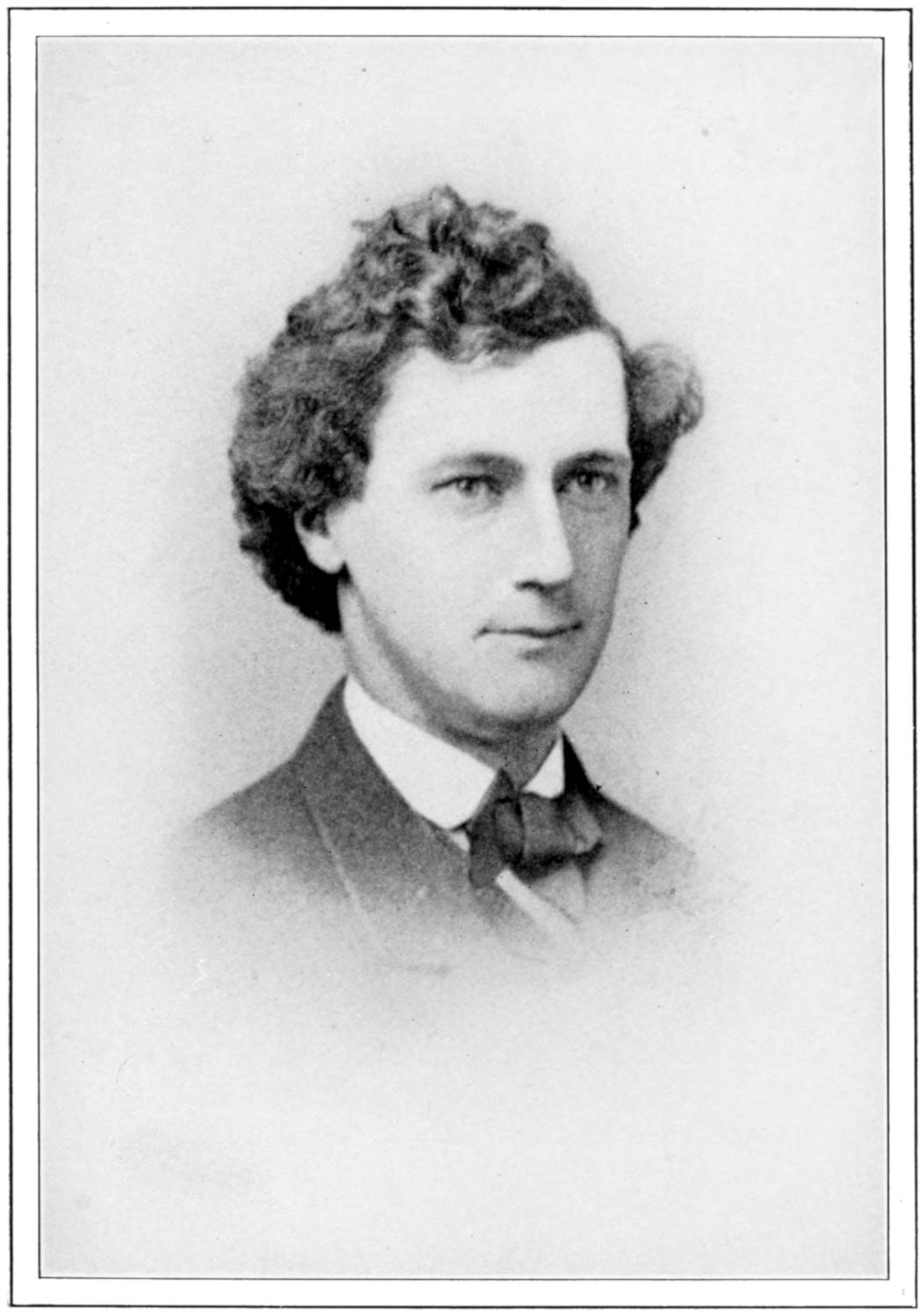

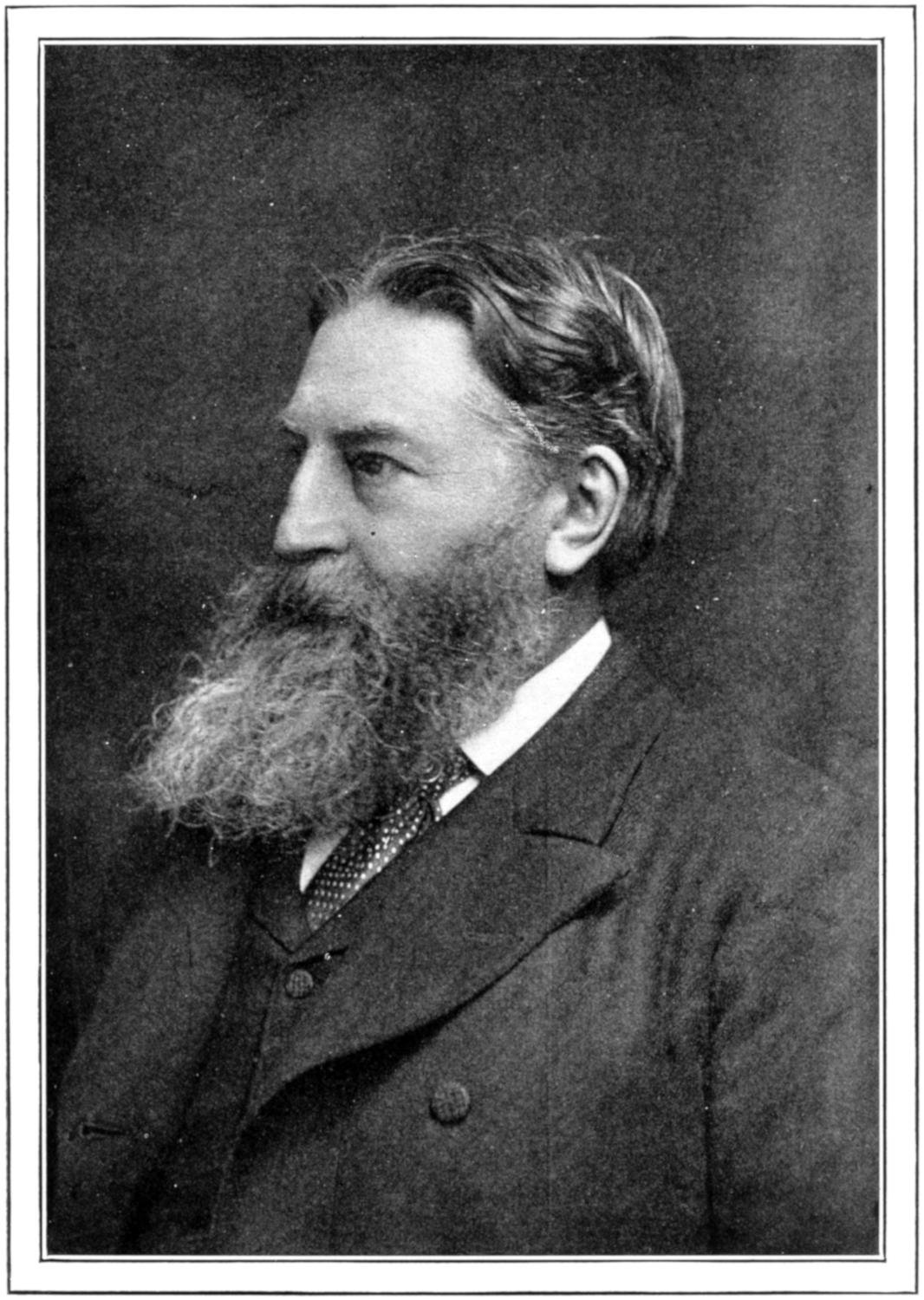

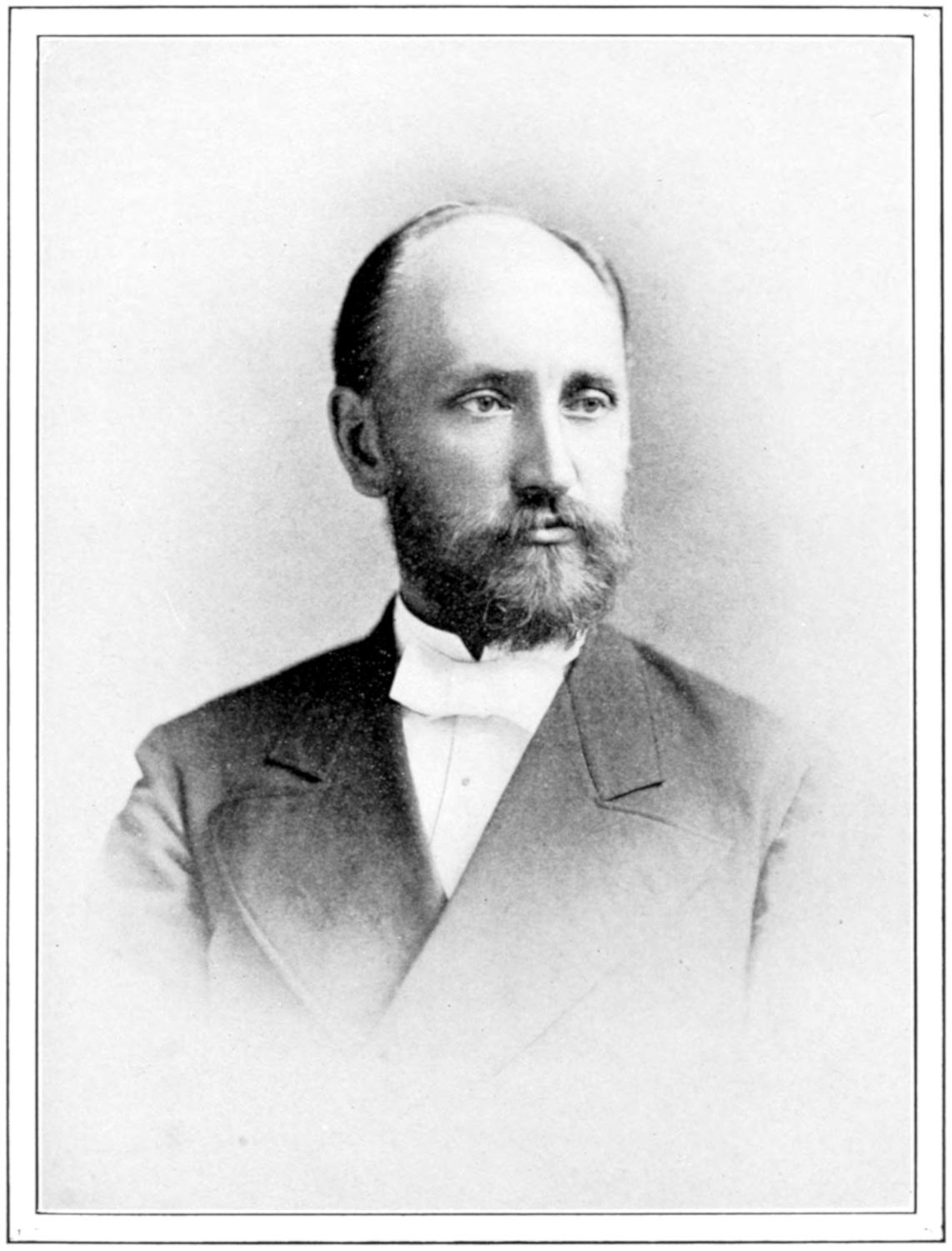

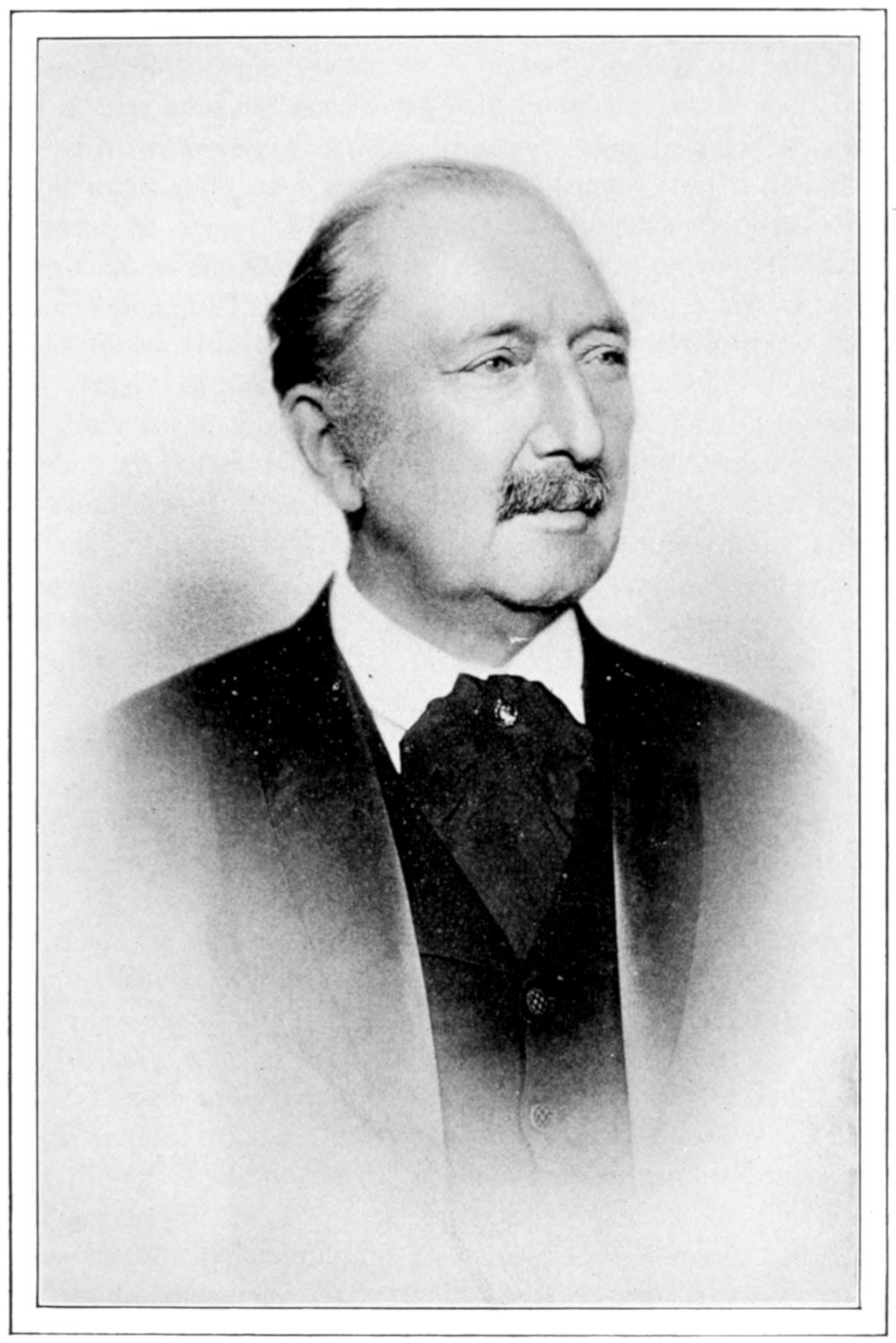

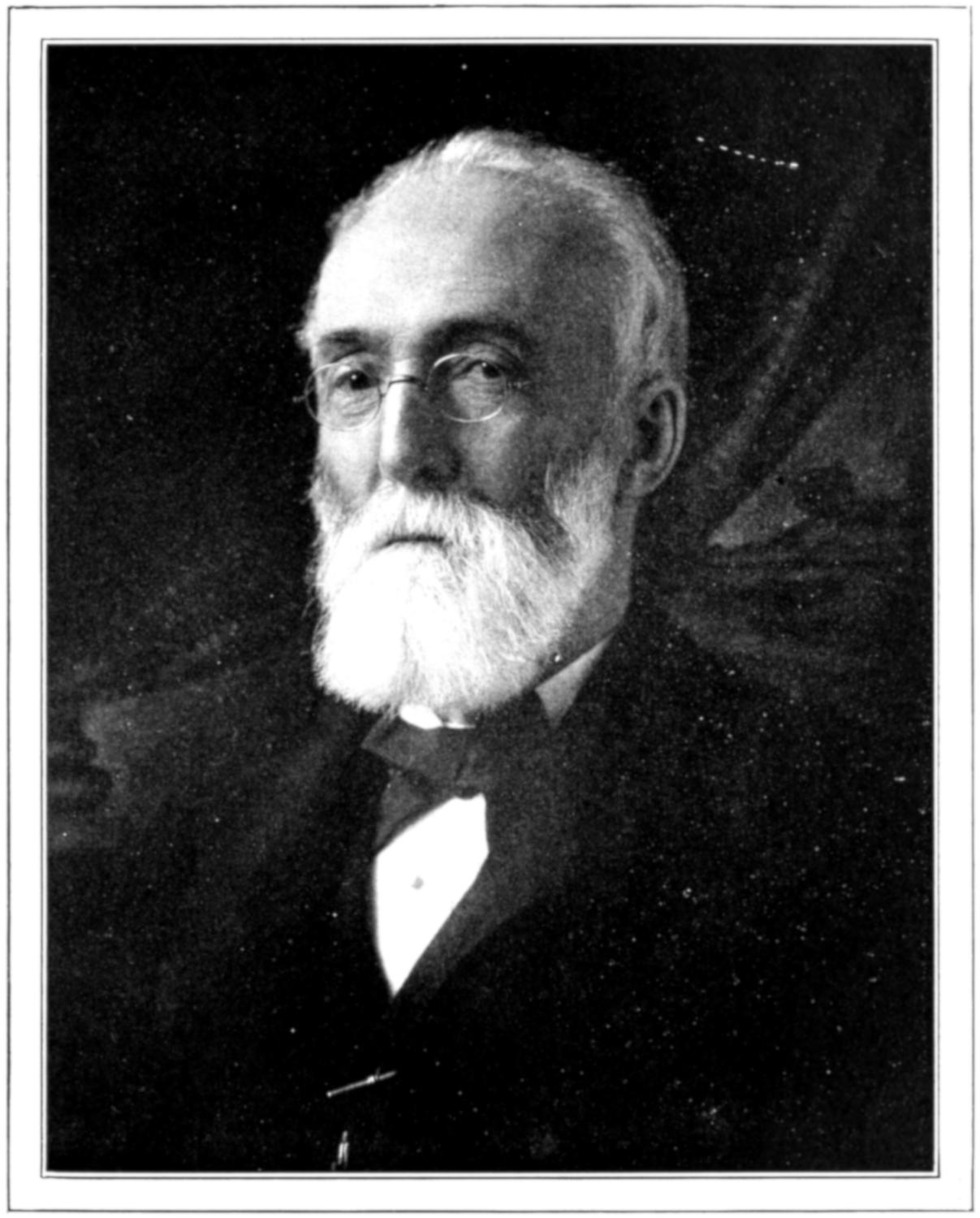

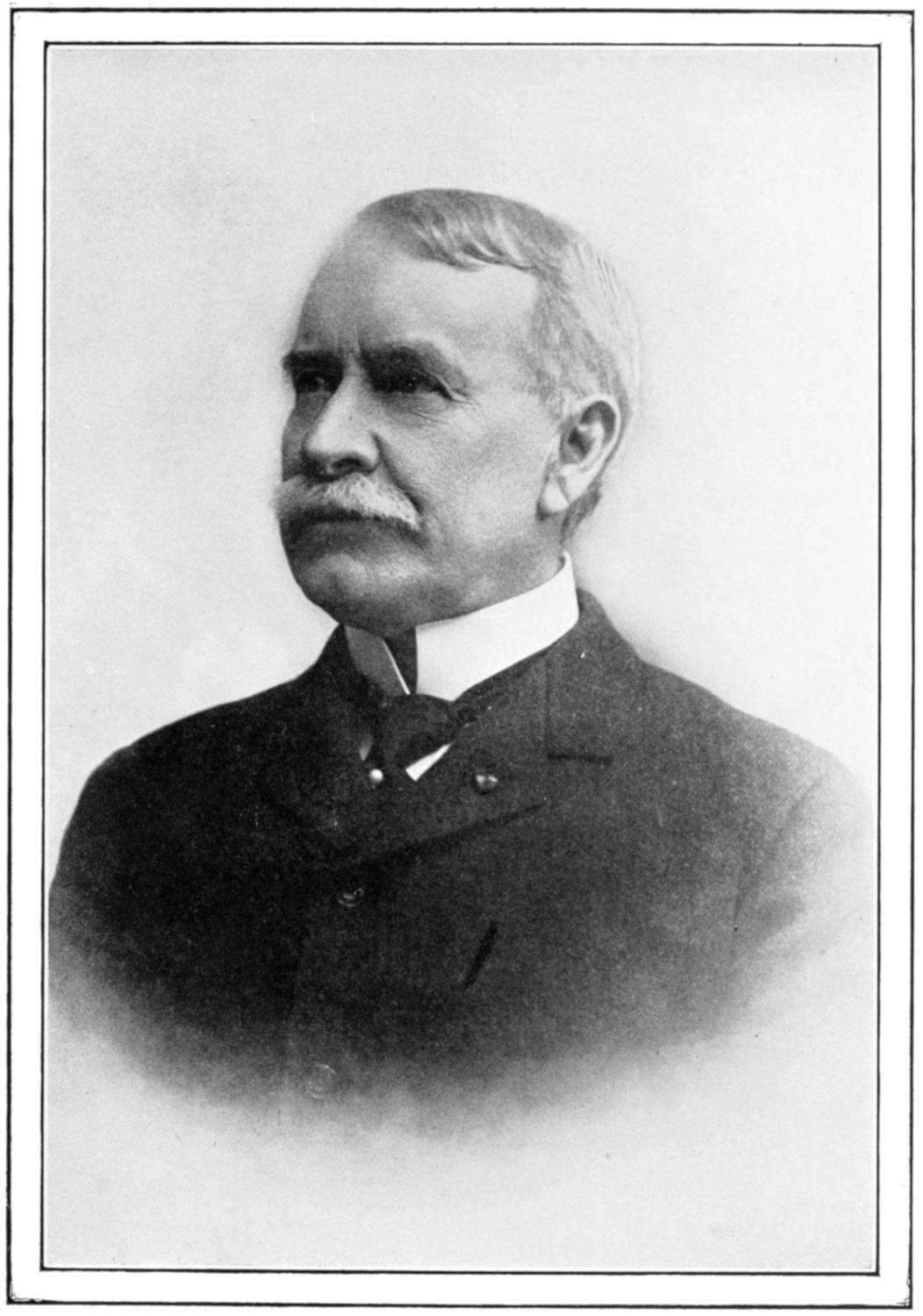

| 1. | Charles T. Porter | Facing title page |

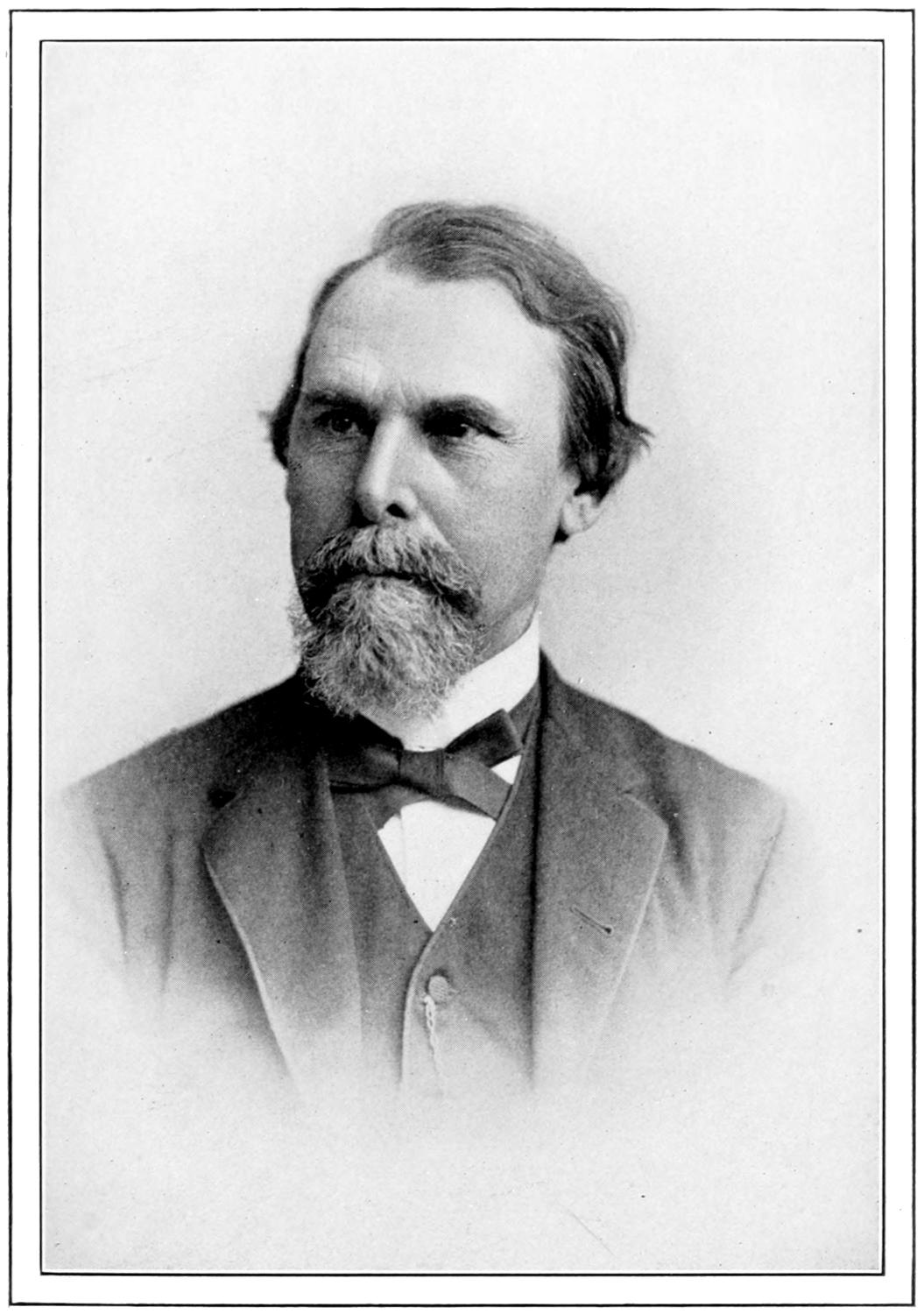

| 2. | My Father | After dedication |

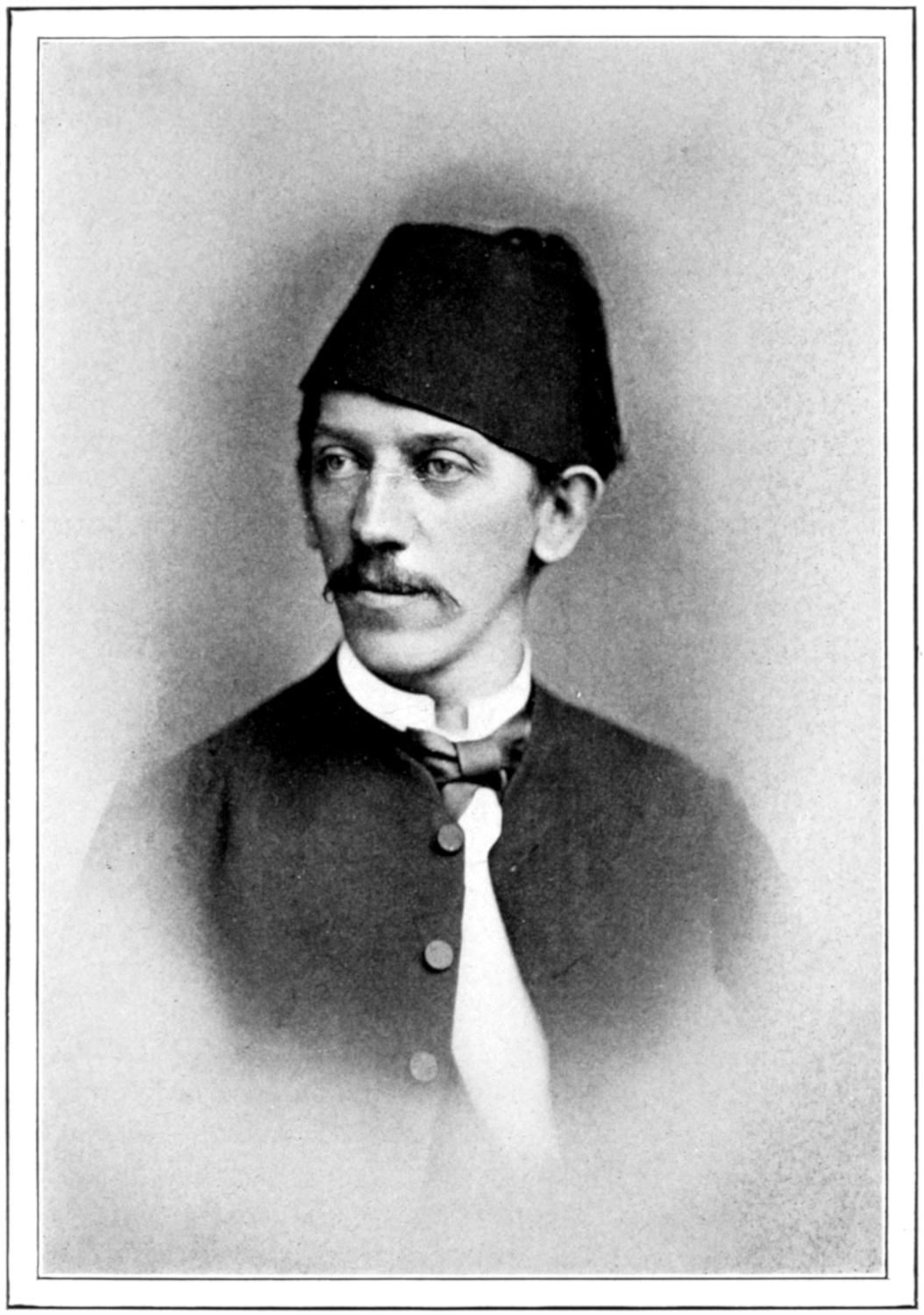

| 3. | My Mother | After dedication |

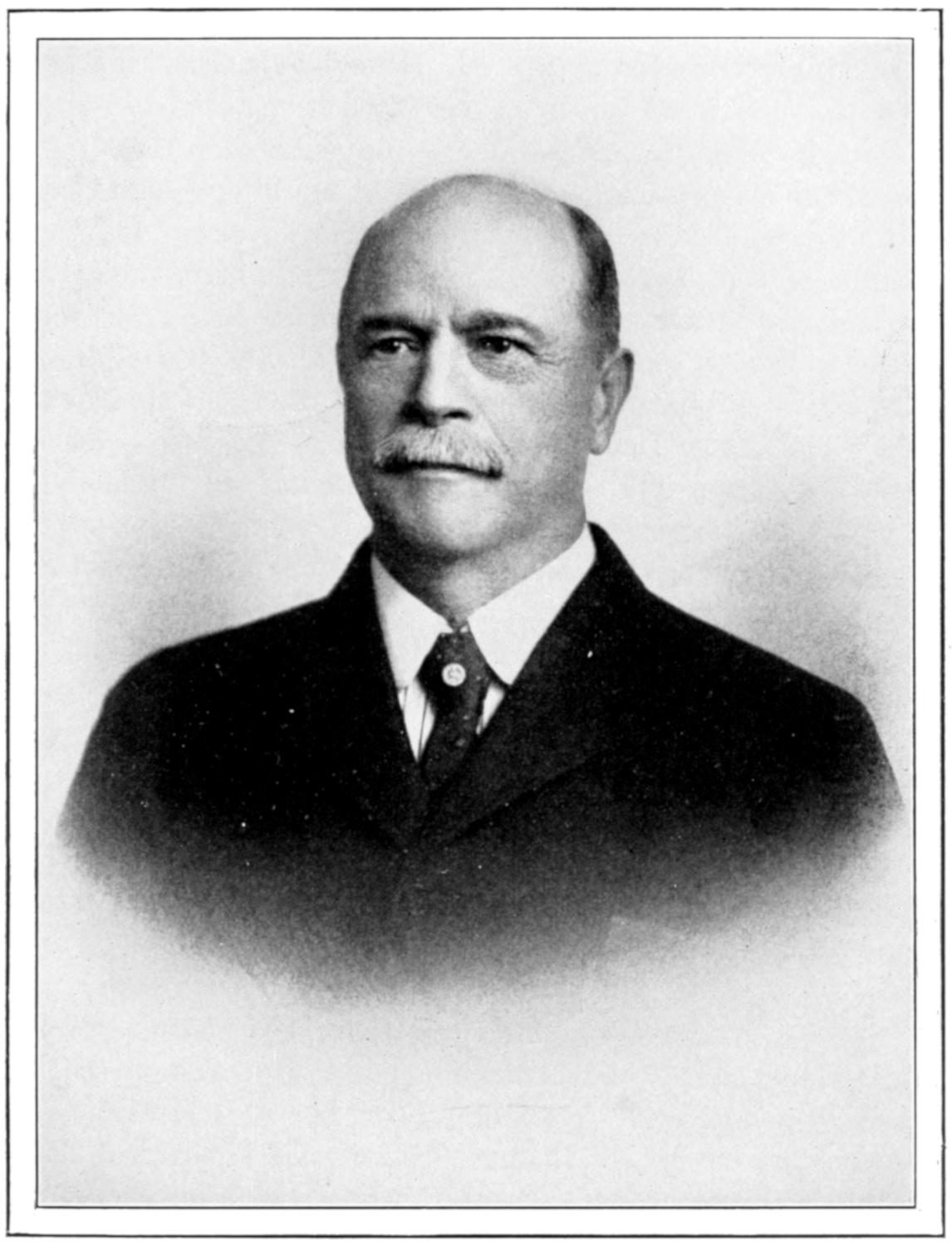

| 4. | George T. Hope | 6 |

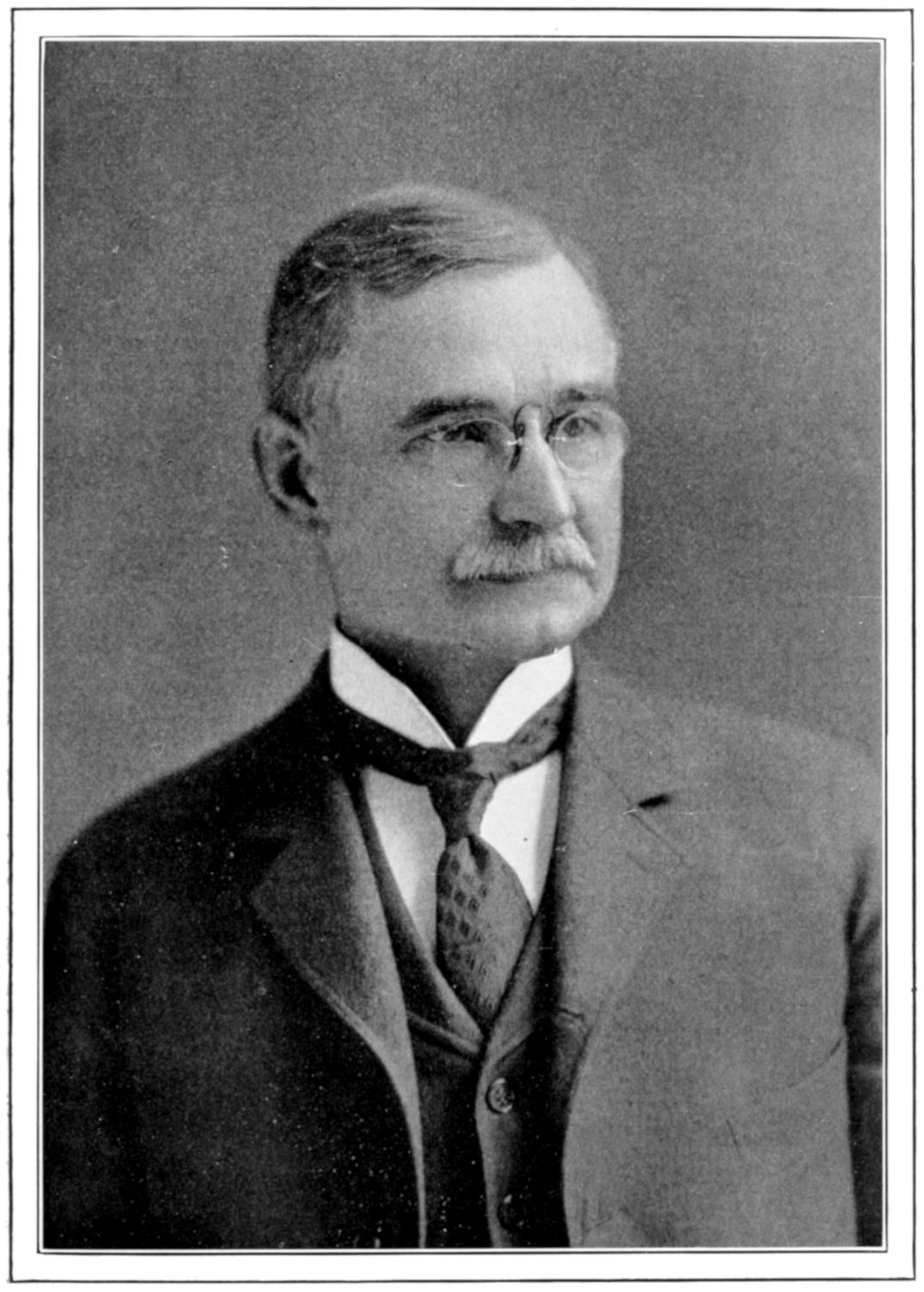

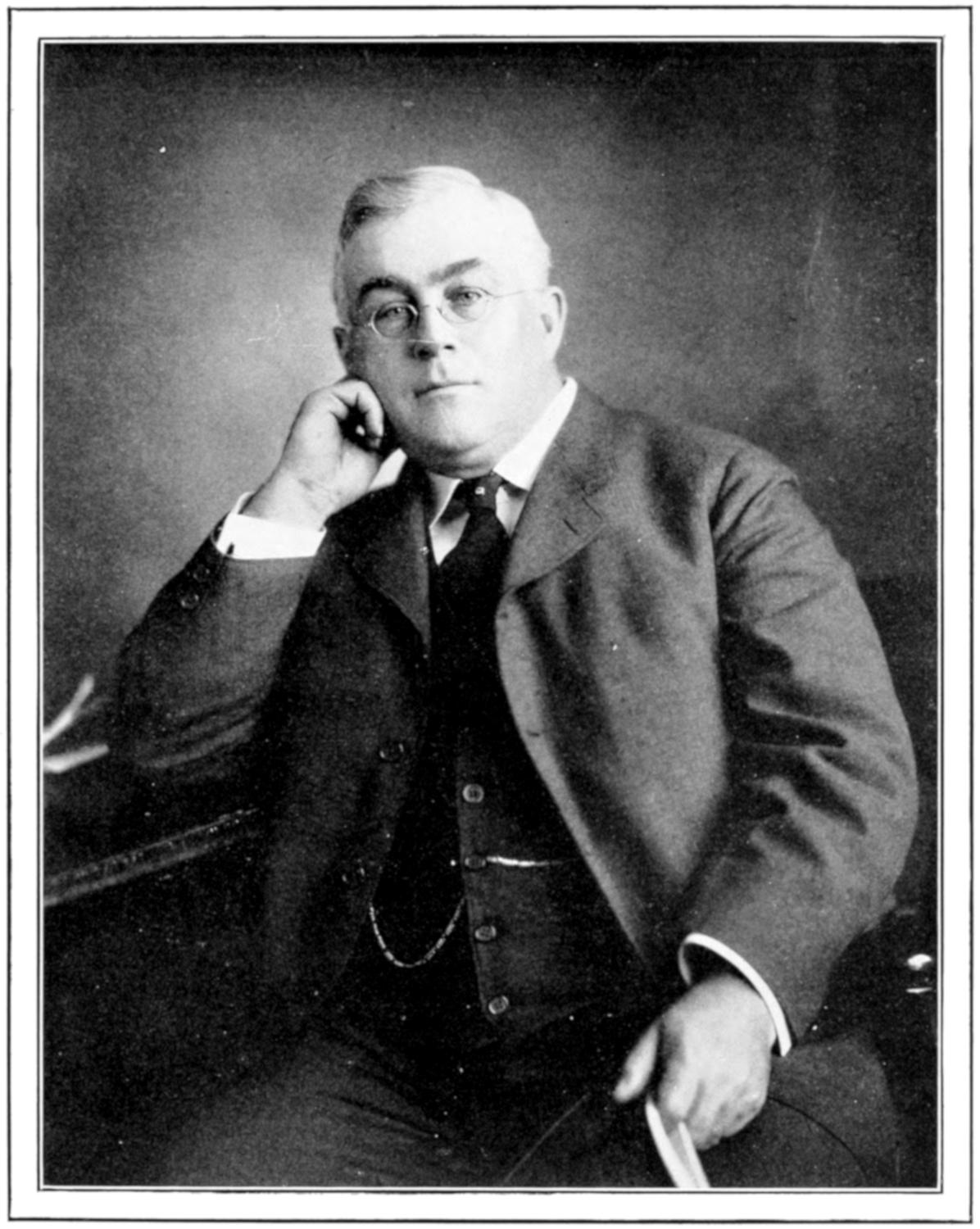

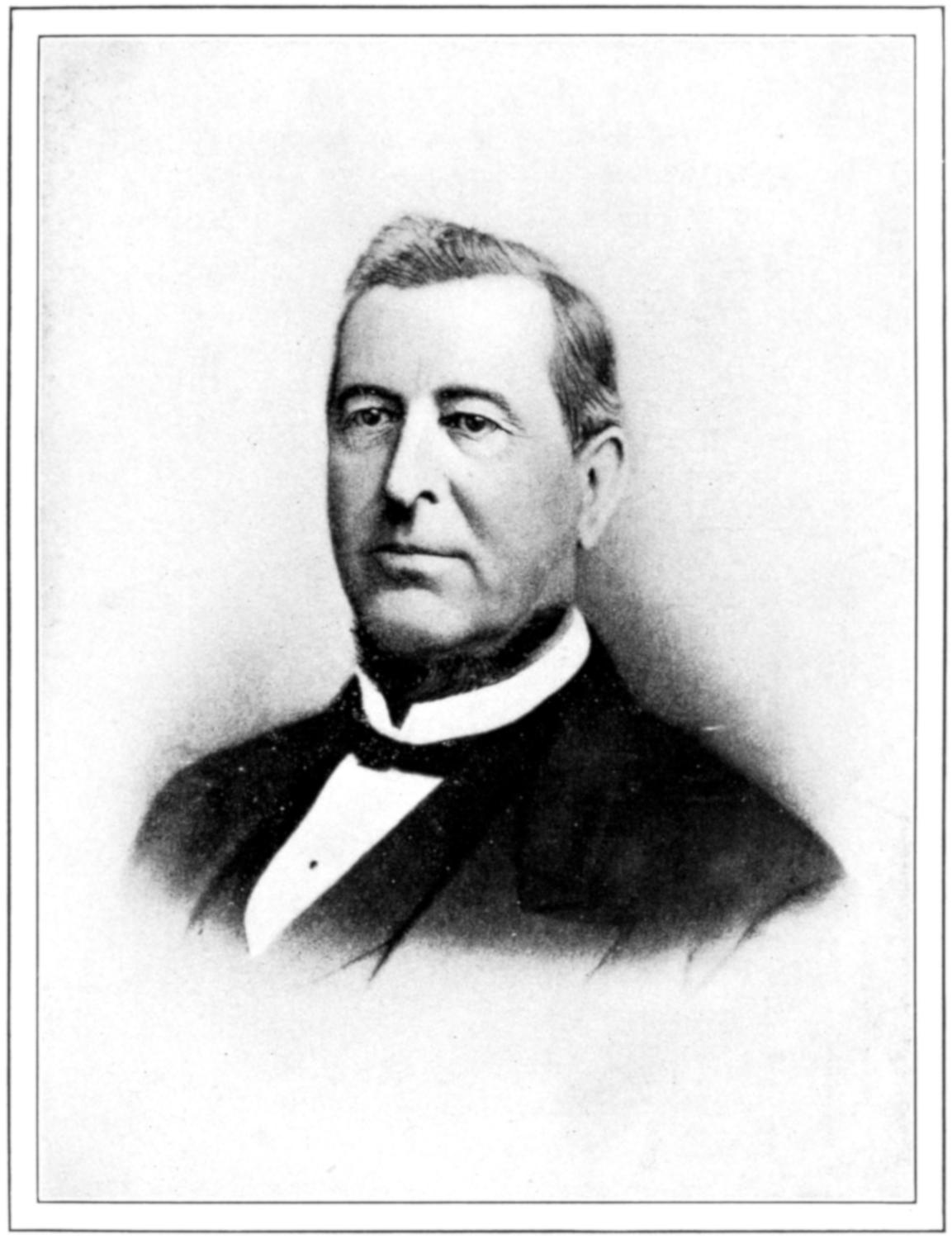

| 5. | Charles B. Richards, a.d. 1858 | 26 |

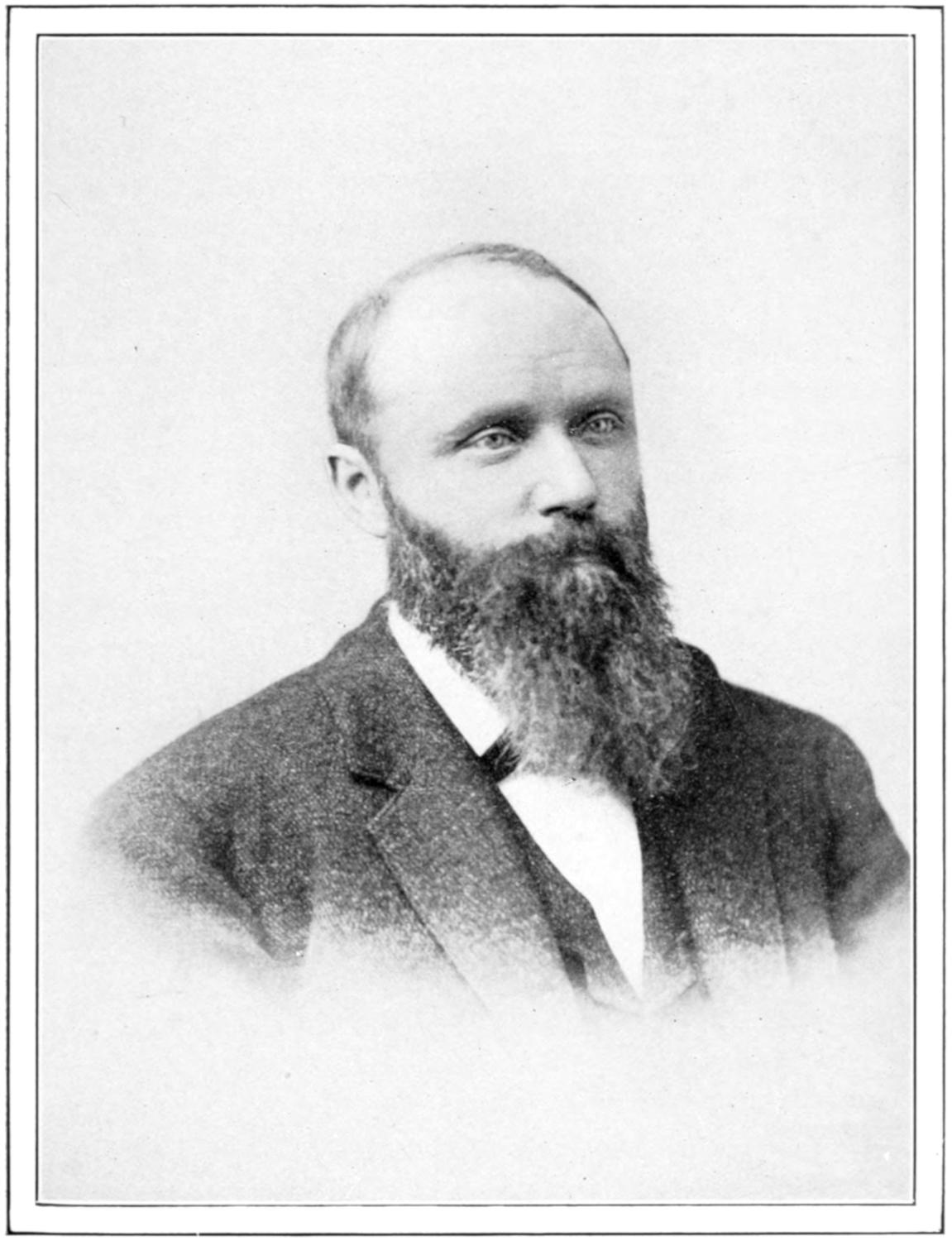

| 6. | John F. Allen | 48 |

| 7. | Joseph E. Holmes | 60 |

| 8. | Alexander Gordon | 62 |

| 9. | Wellington Lee | 66 |

| 10. | Charles T. Porter, a.d. 1862 | 68 |

| 11. | Frederick E. Sickels | 78 |

| 12. | W. H. Maw | 92 |

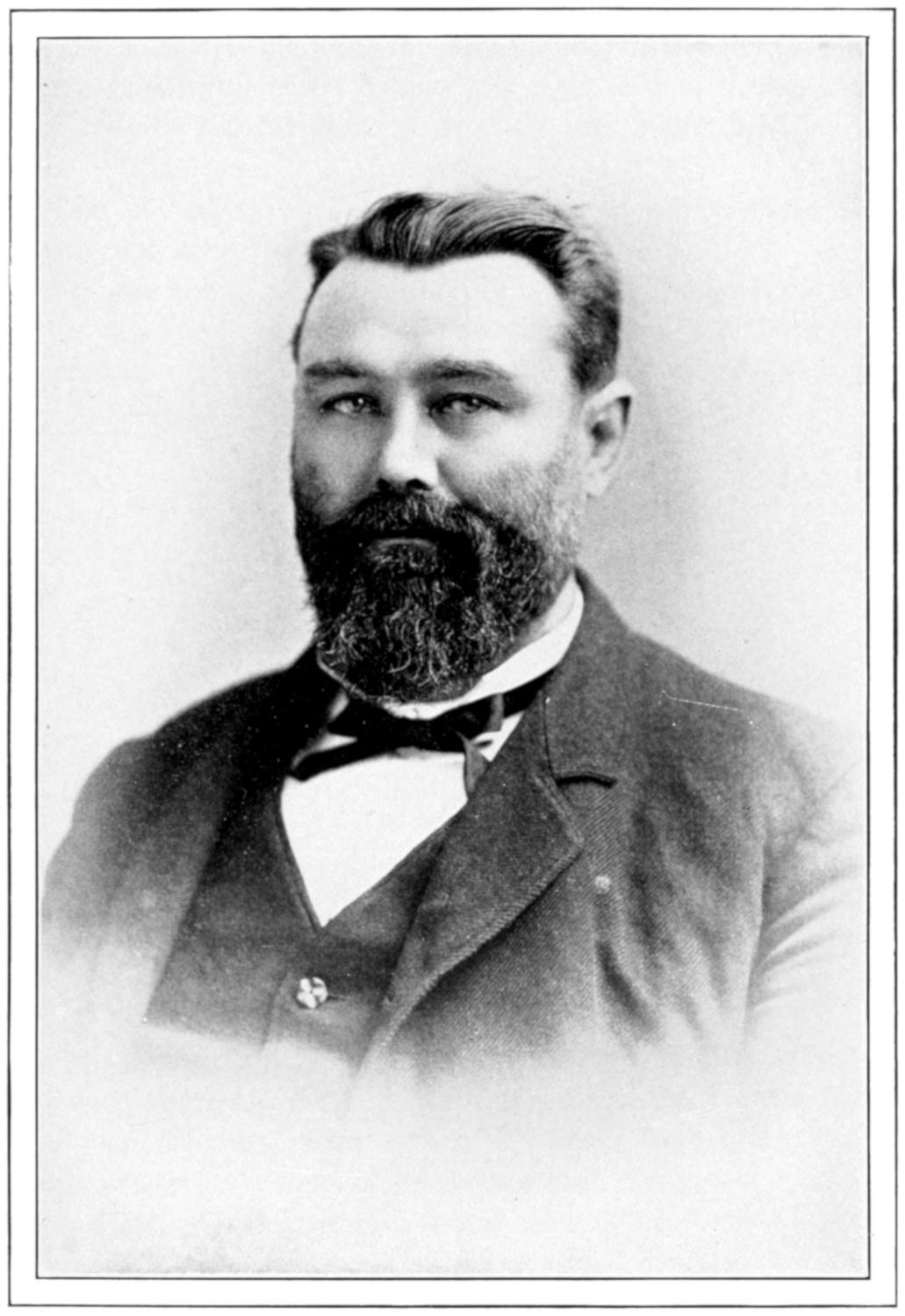

| 13. | William J. Hoyle | 122 |

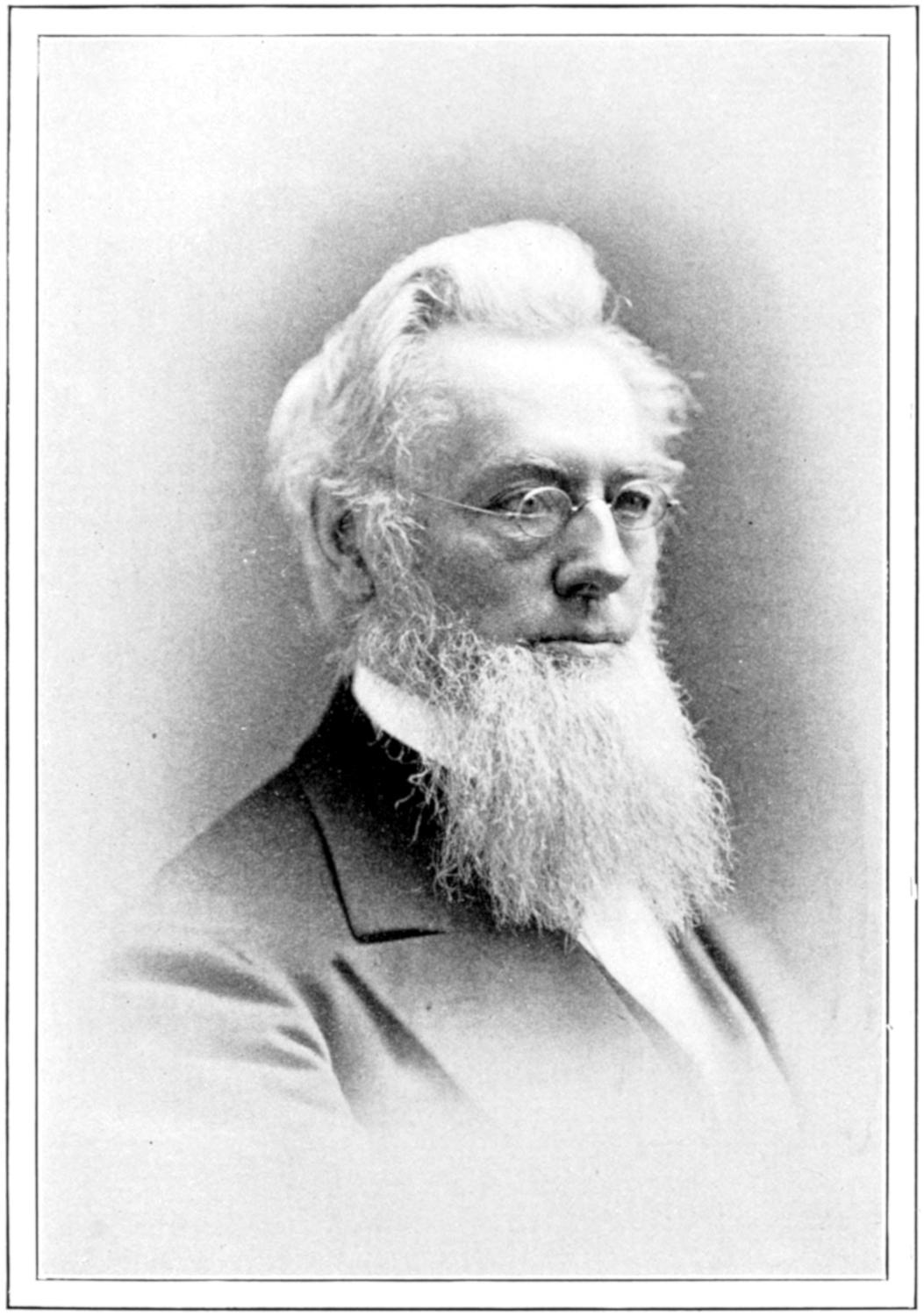

| 14. | Sir Joseph Whitworth | 124 |

| 15. | Frederick J. Slade | 154 |

| 16. | Professor Charles B. Richards | 178 |

| 17. | President F. A. P. Barnard | 198 |

| 18. | Joseph Nason | 204 |

| 19. | Edwin F. Williams | 206 |

| 20. | Professor Robert H. Thurston | 208 |

| 21. | J. C. Hoadley | 220 |

| 22. | Alexander Lyman Holley | 238 |

| 23. | William R. Jones | 244 |

| 24. | Professor Francis Reuleaux | 246 |

| 25. | Colonel Alexis Petroff | 252 |

| 26. | James Moore | 254 |

| 27. | Emil Brugsch | 256 |

| 28. | Robert W. Hunt | 262 |

| 29. | Stephen W. Baldwin | 264 |

| 30. | Harris Tabor | 266 |

| 31. | Daniel N. Jones | 272 |

| 32. | John Fritz | 274 |

| 33. | E. D. Leavitt | 308 |

| 34. | Samuel T. Wellman | 310 |

| 35. | Charles A. Otis | 312 |

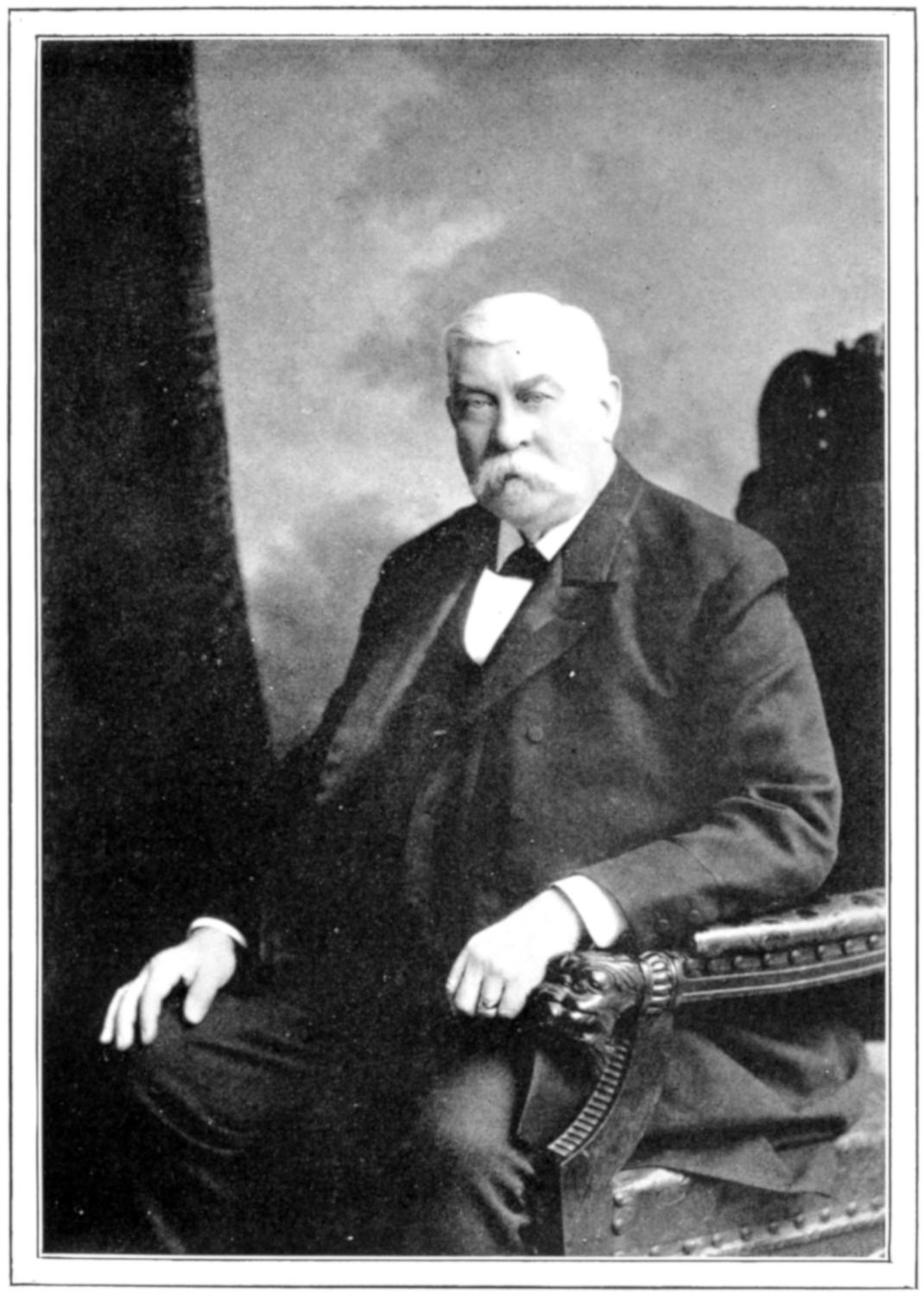

| 36. | Daniel J. Morrell | 314 |

| 37. | Benjamin F. Avery | 324 |

| 38. | James C. Brooks | 332 |

[1]

ENGINEERING REMINISCENCES

CHAPTER I

Birth, Parentage and Education. Experience in the Practice of Law. Introduction to Centrifugal Force. Invention and Operation of a Stone-dressing Machine.

I was born in Auburn in the State of New York, January 18th, 1826. My parents were both of New England descent. My father, John Porter, was born in Hadley, Mass. His father, William Porter, was the son of Eleazer Porter and his wife Susannah, one of the daughters of Jonathan Edwards. My father’s mother was Lois Eastman. My mother was born in Middletown, Conn. Her maiden name was Abigail Phillips. Her ancestry in the maternal line is traced back to Governors Saltonstall, Dudley and the two Winthrops.

I graduated at Hamilton College, New York, in 1845, read law in my father’s office, and in the fall of 1847 was admitted to the bar. Practiced my profession for six or seven years, first in Rochester, N.Y., afterwards in New York City.

My knowledge of mechanics may be illustrated by a story I once heard in England of a man who had been prosecuted for selling adulterated tobacco. He got off by proving that there was no tobacco at all in the article that he sold. But this illustration hardly does the case justice.

I had some mechanical ideas, but they were exactly wrong. For example, I could not see any difficulty in perpetual motion. All one had to do was to pump up water, which by its fall would furnish power to run the pump. This, however, was no more absurd[2] than were two inventions which were brought out in England while I was there. One of these was corrugating the faces of the piston, so as to present more extended surfaces for the steam pressure to be exerted upon. The other was a device for utilizing that half of the force of the steam which had been wasted against the cylinder heads. Both of these were published with commendatory remarks in the Mechanics’ Magazine. The last, if I recollect rightly, was the original bottom feature of the Wells balance-engine. My error was that I made no account of friction, which must be overcome before motion can take place. We shall see before long the same disregard of friction by men who ought to have known better.

My utter ignorance of everything mechanical at that time is capable of proof. I stepped right into one of those “springes to catch woodcocks” which were being set in those days, and proved myself to be about as green a gosling mechanically as ever was plucked.

I had a client by the name of Searle, who was a “dead-beat.” He owed me about $100, which I could not collect. He finally called upon me and told me frankly that he could not pay me one red cent, because he had no money; but he could put me in the way of making a fortune, and he was anxious in that way to discharge the great obligation which he felt himself under to me.

A new invention had appeared, called the Gwynne & Sawyer static-pressure engine, that was bound to revolutionize all applications of power. It was, he told me, attracting great attention in engineering circles, and there had been a hot discussion over its theoretical principles, but its advocates had successfully vanquished all their antagonists and now the invention was established on a perfectly sound scientific basis. If I would give him a receipt in full for the money that he owed me and put another $100 into this enterprise, he was in a position to secure for me a number of rights to use the machine. He kindly offered to introduce me to Mr. Sawyer. Mr. Gwynne was unfortunately absent from home at the time. (I learned afterwards that he was in jail.) Mr. Sawyer received me most graciously. I think he had been told by Mr. Searle about how much taffy I might be expected to swallow, but he must have ventured far beyond his instructions.[3] He told me that he was delighted to make my acquaintance; he had frequently heard of me through our mutual friend, Mr. Searle, and of my triumphs at the bar, and had come to feel a great admiration for me, and was proud to show this great invention to a man so eminently capable of appreciating it. He told me that the invention was a practical method of utilizing that wonderful power known as centrifugal force. This force could be obtained in any amount. In fact, it was the force that kept the universe in motion. It had lain unutilized for so long a time because engineers had never been able to apply it practically. This difficulty had been completely overcome in this great invention, and this wonderful power was now to be made available for the world. He gave me quite an oration on the subject, saying, “We do not antagonize the forces of nature, we utilize them and apply them to beneficial purposes; consequently all nature co-operates with us,” and more to the same effect. He was able to show me a working model of this great invention; was very sorry that he could not put it in motion for me that day, as it happened to be a little out of order; but I would be able to see the principle of its operation very distinctly. I was flattered into believing that I saw the principle, with the result that Mr. Sawyer saw the principal, and with the further result that after that I never saw or heard of either principal or interest. Our mutual friend, Mr. Searle, also disappeared.

This was my first lesson in mechanics, given to me by a master of his art. I am not sure, on the whole, but that in one way and another it has been worth the trifle it cost me.

Had any one at that time told me that the expression “centrifugal force” is entirely misleading, that in reality there is no such force, that what goes by this name is not a force at all, nothing but a resistance, the resistance which a body revolving around an exterior point opposes to being continually deflected from a straight line of motion, and which ceases the instant the deflecting force ceases, when the body merely moves on in a straight line tangent to the circle, and in bodies revolving around their own axes or centers of gravity is the same resistance of their atoms, he would probably have had about the same success in making me see it that I long afterwards had with some engineering friends.

[4]

It is difficult at the present day to conceive the confusion of thought which then prevailed on this subject. The language of text-books was vague in the extreme.

The coincidence is not without interest, that my first mechanical experience, though in this ridiculous fashion, should have been with what was to become so prominent a feature of the high speed governors and engine.

I had for some time felt a growing disgust with the profession of the law. The contrast between the glorious science of human rights and the art of its practical application was very forcibly presented to my mind. I realized the fitness of the protest of Bryant, who described himself as being “forced to drudge for the dregs of men.” I was a regular reader of the Evening Post, in which an article appeared one day, written by John Bigelow, then the editor of the Post, laudatory of a certain judge whose term on the bench had lately closed, and who then retired from the profession. On this act Mr. Bigelow warmly congratulated him. Among a number of pungent expressions in the article I was particularly struck by this one: “The association of lawyers is mostly with knaves and fools.” My own experience bore witness to the truth of this statement. A few legal successes, which cost me incredible labor, interspersed of course with disappointments, weighed nothing compared with the daily association which I seemed compelled to endure. I formed a scheme for establishing a conciliation office for the amicable settlement of disputes, but found every man prepared to compromise on the extreme verge of his own position. So I gave that up.

I had another client, a Mr. Hastings, who had invented a stone-dressing machine, which he had patented, and the patent for which he wanted to dispose of. He had a working model of his invention, which was operated for visitors in the shop where it was built. He invited me to go and see it, which I did, and it certainly worked very well indeed. I recalled afterwards that the stone was carefully bedded on the table of the machine. I was quite fascinated with it and took some friends to see it, who were equally captivated, and the result was that we bought the patent. To make sure of its value, however, I first called with Mr. Hastings on Mr. Munn,[5] his patent solicitor, and received Mr. Munn’s assurance that he had a very high opinion of it.

I gradually abandoned my law business, and devoted myself to the exploitation of this invention. I put into it all the money I had and all that I could borrow. After a while a large working machine was completed for us, the drawings for which I had made by a German draftsman, and which was built under my direction at the works of Mott & Ayers, near the foot of West Twenty-sixth Street. When this machine was finished the parties in interest assembled at these works to see it tried.

One experiment was enough. I had put into the machine a stone that was quite a foot thick and which was supported at two points. At the first cut made across this stone it broke in two in the middle. I found myself, in the words of President Cleveland, “confronted not by a theory but by a condition.” The machine was absurd. The patent was worthless. The enterprise was a failure. Our money had all been thrown into the sea. Nothing could be done unless I did it; and I knew nothing of mechanics, of machine design or construction, or of mechanical drawing, except the little that I had picked up in the works of Mott & Ayers while this machine was in process of construction. I should say, however, that the head draftsman in that establishment had given me some instruction in mechanical drawing, so that I knew the use of the instruments and what kind of ink to use.

I cannot recollect that I was in the least cast down or discouraged. I cannot now account for my confidence. I believed that the fundamental features of this machine were correct. These were: cutting stone by a blow given by a hammer moving in an inclined direction, and which was thrown up by a cam and thrown down by springs. The more I reflected upon it the more I became convinced that a successful stone-dressing machine could be made on those general lines, and in no other way; and I also became impressed with what seems the almost absurd conviction that I could make it.

The machine that broke the stone had a broad hammer—a cast-iron plate with tongues on the sides running in grooves in a frame,[6] and to the end of which a long steel blade was bolted. My first idea was to divide the single broad hammer into several hammers working side by side and striking their blows successively; the second was to separate the hammers from the tool-holders, the third, to employ the same tools that were used by stone-cutters, namely, the point, tooth-chisel and drove, and to give them as nearly as possible the same blow that was given to them by the workman, and the fourth, to give to the tools only the blow necessary to do their work.

I infused my own enthusiasm into my associates to such a degree that they agreed to put up the money and let me try the experiment. That also is something that I now wonder at.

The most influential member of this devoted band was George T. Hope, President of the Continental Fire Insurance Co., a gentleman whom I shall have frequent occasion to mention, and who remained my steadfast friend till his death, which occurred soon after the close of my engineering career.

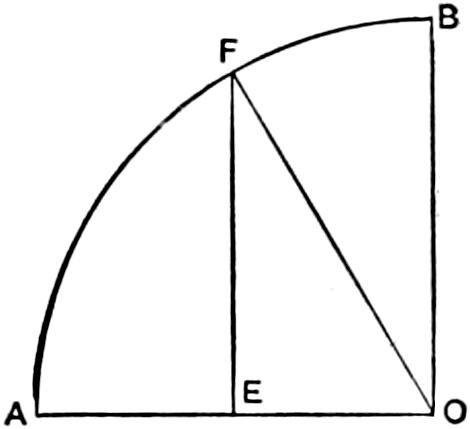

I set about my work in this manner. My house, on the south side of Twenty-second Street west of Seventh Avenue, had been arranged in its construction to use the extension room back of the parlor as a dining-room. That left the front basement available for me. This I equipped for a drawing-office, and set myself at work to learn mechanical drawing, and at the same time to design this machine. I bought a Scotch instruction book, and a sheet of “antiquarian” drawing-paper. In those days all drawings were made on white linen paper, and this was nearly the largest size that was made, and cost 75 cents a sheet. My principal drawing-implement was india-rubber. As my plans grew in my mind I had to rub out my preceding sketches. I spent a great deal of my time in visiting the large engineering works on the East River—the Allaire Works, the Morgan Works and the Novelty Works—and studying tools and machines and principles and methods of construction. I tried to get my mind saturated with mechanics. I finally succeeded in producing the design, this vertical section of which I have sketched from memory after fifty years.

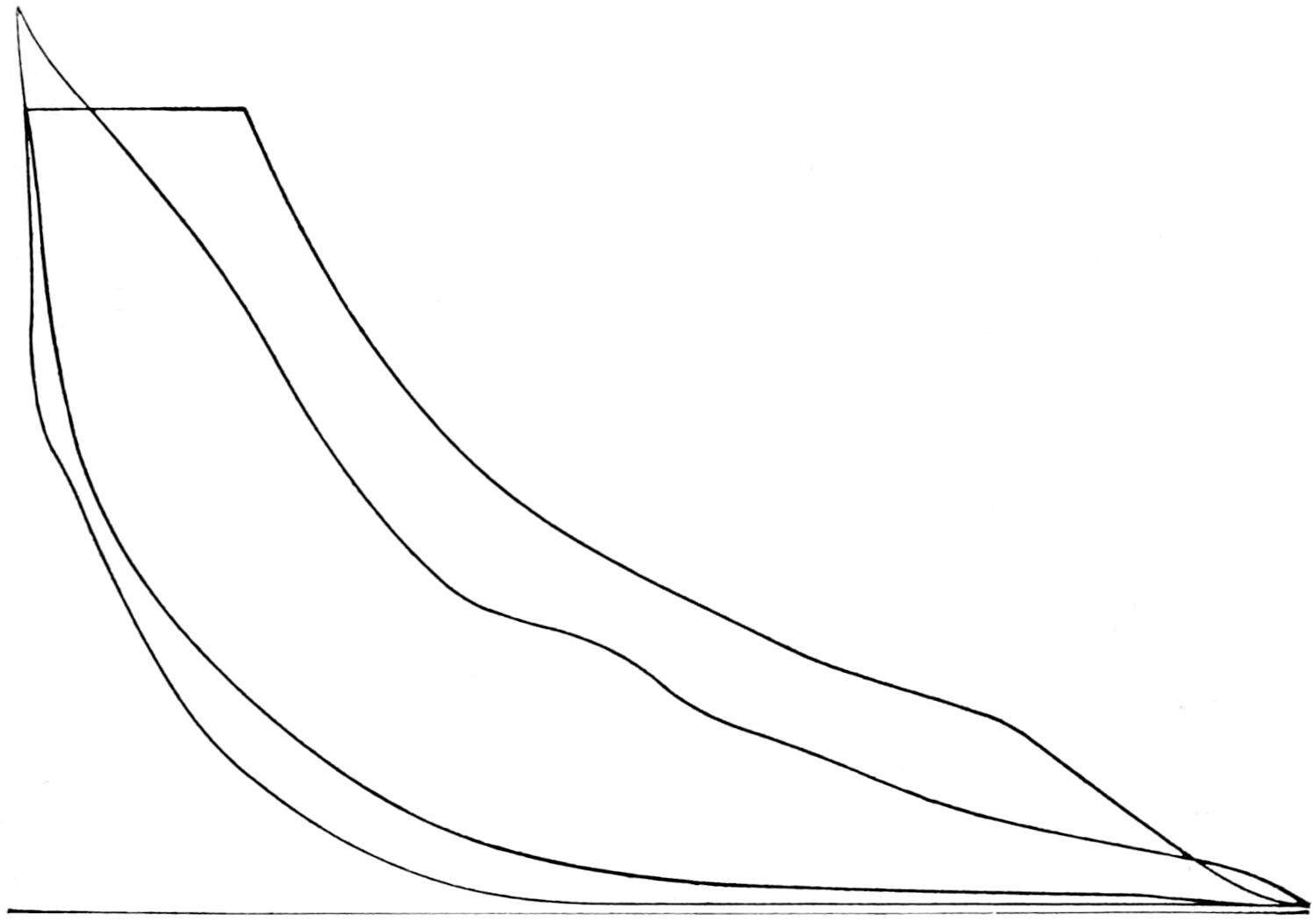

It will be seen that this machine was massive in its construction. This was required on account of the speed—300 rotations of the shaft per minute—at which I had determined to run it. This was my first employment of high speed.

[7]

George T. Hope

The original model of the machine made 60 strokes per minute. In the machine that broke the stone I had increased the speed to 100 strokes per minute. In designing the successful machine I made the great jump to 300 revolutions of the cam-shaft per minute. This was done after much study of practical requirements. I observed carefully the speed of planing-machines. I had also the opportunity of witnessing the operation of the first wood-moulding machine, and was much impressed by the speed of the rotary cutters and the rapidity with which the work was turned out. I wanted a motion of 40 inches a minute for the stone table, which would make the output of the machine satisfactory; 300 revolutions would give this motion, the table advancing .133 of an inch at each blow.

Side frame not shown, except Channels

for Elevating Screws

My First Mechanical Drawing.

Longitudinal Section of my Stone-dressing Machine.

[8]

The machine contained six hammers, each 6 inches wide and weighing about 200 pounds, which ran in a suspended frame. The front member of this frame was a wrought-iron bar 6 inches square, with a projection on the lower side, as shown. At the ends this bar was first reduced to 5 inches square, the corners rounded to 1 inch radius, and mortised into cast-iron side-bars 4 inches thick, one of which is shown in the sectional view. Beyond these side-bars the wrought-iron bar was turned down to journals 3¹⁄₂ inches in diameter, which turned in the heads of large screws, one of which is represented. Beyond those journals it was further reduced to 2 inches diameter, and the ends threaded. These projections extended through slots in the main framing, and nuts on the outside provided with long handles enabled the whole to be bound fast in its position, when that had been determined.

The hammers had two faces; the upper faces struck on this 6-inch square bar, the lower faces struck the backs of the heavy tool-holders. These tool-holders were held in position in the manner shown. At the extreme back end they rocked downward upon a heavy cross-bar. At the front they rose against the 6-inch cross-bar. They were made with a heavy hook at the back, which prevented them from coming forward further than the projection at the bottom of this cross-bar permitted. A curved spring held them up to the cross-bar when the weight of the hammer was removed. Between the 6-inch cross-bar and the tool-holders and the hammer faces I introduced a sheet of heavy leather belting, which deadened the force of the blow. A stone-cutter uses a wooden mallet to drive the tooth-chisels and droves, because the impact of iron on iron has a disintegrating effect upon the stone, which the stone-cutters call “stunning the stone.” It produces a vibration in the body of the stone to a depth of perhaps ¹⁄₈ inch, and, however well the surface of the stone may appear when it is finished, after a while the outside will flake off to the depth to which these vibrations have extended. This leather buffer served the purpose of the wooden mallet, completely avoiding this difficulty. Incidentally also it made the building habitable, by transforming the blow into a dull thud, which at the rate of 1800 blows per minute from the six hammers was itself quite important to be done.

[9]

The large screws on each side of the machine at the front were provided at the top with long nuts resting on a cross-bar and combined with worm-wheels. A shaft carrying two worms engaging with these wheels extended across the top of the machine, so that the nuts were rotated identically, and the front of the suspended frame was raised or lowered as the thickness of the stone or depth of the cut required. The machine could cut stone from the thinnest ashlar up to a thickness of about 3 feet. The hammers ran on rollers as shown. At the back the frame and hammers were carried on similar rollers on the same shaft. The ends of this shaft also turned in square heads of screws, and by a mechanism similar to that already described the back of the frame could be elevated or depressed to the height required and be set at any desired angle.

The six tool-holders were made in the following manner: I got from England a bar of steel long enough to make them all. This was planed into the form shown in the section, and the sockets for the shanks of the tools were finished to an equal depth and perfectly in line. It was then parted, and the ends of each finished in a slotting-machine.

The blows struck by the hammers were very effective. The cams had a throw of 1¹⁄₄ inches, but they threw the hammers back against the springs 1¹⁄₄ inches further, making their fall 2¹⁄₂ inches. This I ascertained by holding a piece of thin board edgeways between the upper end of a hammer and the cross-bar at the back, when the hammer crushed it up to this height.

We never ran over the stone with the points but once. They made everything before them fly. On the other hand, the droves merely dusted the surface, to take out the marks of the tooth-chisels. All surplus force in the blow was received on the 6-inch cross-bar. The tools stood motionless unless pushed back by the stone, when they received a sufficient portion of the blow to drive them forward to their position.

The feed motion was powerful, being imparted by a worm engaging in a worm-wheel 24 inches in diameter, while the run back was swift, quite 100 feet in a minute.

The sides of the steel tool-holders, rubbing against each other, became after a while badly abraded. I was obliged to plane[10] them off and dovetail thin strips of hardened steel into them. These prevented any further trouble. The sides of the end tool-holders, however, which rubbed against the cast-iron side-bars, I observed, were polished without sensible wear.

This was a very important observation. These surfaces all rubbed together dry. The pressure was only the side thrust, which was very trifling. Under these conditions the molecules of the same material interlocked, while those of the different materials did not. These two materials were, however, extremely different in their constituent features. Perhaps this point of freedom of some different materials from interlocking was still better illustrated by the set-screws, where this difference of molecular structure did not exist in the same degree. These were made of Ulster iron, a superior quality of American iron then largely used in New York City for bolts. They were ⁵⁄₈-inch screws, and were also used dry, no oil being allowed anywhere over the stones. Each tool-holder contained three of these set-screws. The outside ones were tightened and loosened sixty times every day. The middle ones, where only the points were used, were tightened and loosened twenty times every day and at other times stood loose in their threads. The tool-holders being massive, and the blows of the hammers also coming on the leather cushion, there was no vibration. At the end of the two years’ running the outer bolts were all perfect fits. The middle ones were loose, but still held the tools perfectly.

The rollers on which the hammers ran were hardened and turned on hardened shafts. The hammers themselves had chilled faces, and their surfaces running on the rollers were also chilled. The surfaces of the tool-holders and of the bar on which these rocked were provided with hardened strips to the extent that they came in contact with each other. The cams and rollers and their pins were also hardened.

When built this machine was found to require only a single alteration. I had welded the cams onto the shaft, the welds being guaranteed by the smith to be perfectly sound. No appearance of unsoundness could be detected when the shaft was finished, but after running a week or two the cams became loose. This also gave me a useful lesson. I was obliged to send to England for[11] blocks of steel, which were bored, finished and keyed on the shaft in the manner shown, and the working surfaces of the cams were hardened. This required the substitution of new hammers, because the cams could not be threaded through the old ones. The hubs of these cams were 6 inches long, covering the shaft.

Our company, being satisfied from its design that the machine when finished would prove a success, rented from Mr. Astor a large lot on the south side of Fourteenth Street, west of Ninth Avenue, extending through to Thirteenth Street, and erected and equipped a building and established a stone-yard, where the machine ran successfully for two seasons, principally employed in facing ashlar, as the flat-faced stones of buildings are termed. It turned out with ease 600 square feet of finished surface per day, which was the work of thirty men, and it never broke a stone, however thin.

For facing in the machine the stones were set on bars 2 inches thick and 4 inches high, cast on the surface of sliding tables. These were both longitudinal and cross bars, and were provided with holes ³⁄₄ inch in diameter and about 3 inches apart. There were two tables, each 16 feet in length.

Several pieces of ashlar were set upon each table and held by dogs and wedges on these bars. They were wedged up very easily by skilled workmen, so that they would finish at the same level. At one side of the ways on which the tables moved, near each end, was placed a swing-crane, which was double- and triple-geared, so that by means of it any stone that the machine was adapted to cut could be lifted by two men. The operations of cutting the stones on one table and removing the stones and setting others on the other table went on simultaneously, so that the cutting was never interrupted, except to change the tools and the tables. This last was done as follows: Each table, when the work on it was completed, was run rapidly backward or forward to attach it to the other table. It was then connected with this by a couple of hooks, and, the motion being reversed, pulled it into place under the tools, and in doing this took its own place under a crane, so that the work of removing the finished stones and setting rough ones went on continuously at one end or the other of the ways.

In addition to the machine I designed the building and the[12] whole plant and the plan of its operation, which moved like clockwork. I made every drawing myself. The cranes I obtained in Rochester, N. Y., of a pattern which the builders made for railroads for handling heavy freight.

I bought from a stone-dressing company that had failed a rubbing machine called the Jenny Lind rubber, from the fact that it was started the same year in which that songstress was brought to the United States by Mr. Barnum. This rubbing-machine was quite a success. From a central vertical spindle a jointed arm extended in three lengths, each about 12 feet long. The sections of this arm were very deep, so that there was no sag at the end, where the rubbing-plate was driven by belting and could be moved from stone to stone around a circle of 36 feet radius. Half of this circle was sufficient for our use. I made only one change in this machine. The pulleys, two pairs on each joint, one at the top and one at the bottom, about two feet in diameter by three inches face, were of course horizontal. The makers were afraid the belts would fall off; so they made these pulleys with two square grooves, ¹⁄₂ inch wide by ¹⁄₄ inch deep, in their faces, and had corresponding strips of leather sewn on the belts to run in these grooves. I threw all these away and substituted ordinary pulleys with their faces slightly crowning. Never had the least trouble. Indeed, these pulleys did better than I expected. I supposed the belts would need to be taken up occasionally, on account of becoming stretched, but they did not. Perhaps they would have done so if the strain on them had been greater. This rubbing machine resembled the stone-dressing machine in one respect: everything about it was arranged for continuous operation and the largest output.

The business was carried on the first season under the management of Mr. John McClave, a master stone-cutter, and the second season under the management of the firm of Brown & Young, stone-cutters. Mr. Hugh Young, of this firm, has since been prominent in the stone-cutting business in New York.

The machine was found to possess a remarkable advantage over hand work. The sun was called by stone-cutters “the great revealer.” When its rays fell at a small angle on a surface finished[13] by hand they showed very considerable irregularities. The same test showed work in the machine to be true planes. It won a high reputation; stone-cutters were anxious to get their surfaces done in the machine, and we had more work offered us than we could do.

The following incident illustrates the favorable impression made by the machine upon everyone who witnessed its operation:

At a meeting of the Directors of the Company at which I was present Mr. Daniel S. Miller, a gentleman somewhat prominent in financial New York, was late. He made the following explanation. “I thought that before the meeting I would visit the stone yard and see how the work was going on. I stayed longer than I had intended, and I want five thousand dollars more of the stock of this company.”

We were much elated over our success, and plans were made for enlarging the business. I completed the drawings for an additional machine, wide enough to take in platforms, for which provision had been made by me in the plan of the building. The only change suggested by our two years’ experience was the use of air-cushions behind the hammers in place of steel springs.

But the best-laid schemes o’ mice an’ men, the poet tells us,

Our plans were suddenly ruined. A change in the method of facing ashlar was introduced and soon became universally adopted. Instead of being faced by hand, it began to be sawn out of large blocks. I have since wondered why this had not been done long before. Blocks of marble had been sawn into slabs by gang-saws no one knows how long, and all that had to be done was to apply the same system to blocks of building-stone. It was found to cost no more to saw ashlar than it had done to split it out at the quarry. All the cost of facing and much stone were saved. Our stone-cutting machine became useless, and I learned that disappointments were not confined to the legal profession.

[14]

The speed of 300 revolutions per minute had proved to be admirably suited for the machine. Familiarity with this speed in the running of the stone-dressing machine made me alive to the value of high rotative speeds in all cases to which they are adapted.

In looking back over this period I see that the success of the stone-dressing machine was due to the following causes:

First, I went about the work of facing stone by machinery in the natural way.

Second, the machine was superabundantly strong and substantial in every part.

Third, it was made with absolute mechanical truth.

Fourth, the speed was splendid.

Fifth, the blow was peculiar. In the Hastings machine the cutting-tool was driven into the stone. In mine it rested on the stone and was moved back horizontally by the feed. This changed slightly the angular position of the tool-holder, so that the blow was received by it at the lower edge of its back. This gave to the tool a motion forward and upward, so that the vertical effect on the stone was trifling.

This was the vital feature of my improvement, and that in a double sense; for it was only by convincing my associates beforehand that a machine operating in this manner could not break the stone that I was able to obtain their financial support.

Sixth, the two-faced hammer saved the stone from all unnecessary force of the blow.

The final cause of its success was the two-table system. The two operations of setting and cutting occupied each about the same time, and twenty tables each averaging thirty square feet of surface, measured after being squared up, were easily finished in a day of ten hours.

A description of some of the constructive methods employed by me may be interesting:

The bar of steel which was to be made into six separate tool-holders had to have eighteen sockets mortised in it. These were 1 inch square. I had made the tools with square shanks so as to insure their proper position. These mortises must be absolutely in line and of equal depth. These objects were accomplished as follows: A cast-iron angle-bar with planed surfaces was first bolted[15] on the table of the drilling-machine, and for drilling the holes the bar of steel was kept in contact with this angle-bar. A uniform depth was insured by employing a bottoming-drill with a collar formed on the shank. The drilling was finished when this collar rubbed on the steel bar.

I had this work done by Mr. Joseph Banks, whose shop was in a large building at the corner of Second Avenue and Twenty-second Street. Mr. A. S. Cameron, the inventor and manufacturer of the celebrated Cameron steam-pumps, was then an apprentice in that shop. Mr. Banks was an excellent mechanic, and I was greatly indebted to him for the accuracy of the work that I procured. He devised an expanding-drill to cut a groove at the bottom of these sockets, in which the chips from the slotting-tool made in squaring the holes would come off. The finishing slotting-tool I designed myself. I had noticed in all slotting-machines that came under my observation at that time that the tool would spring off a little at the commencement of the cut, so that a full square angle was never obtained. To avoid this defect and to size the slots equally I made a slotting-tool to cut on opposite sides. The cutting edges were each about ¹⁄₈ inch long and the corners rounded. The bar for the tool-holders had to be set three times on account of its length. It was set in contact with the same angle-bar, which was bolted on this table parallel with its transverse feed. This finishing-tool being once set, the upper and lower faces of all the sockets were thus readily finished in perfect line and with square edges. The tool being then turned at right angles to its first position, for which purpose its shank had been planed square, finished the sides of the sockets. These were identical in every respect, and any tool could go anywhere.

The springs behind the hammers were prepared with great care. I had large bars of spring steel reduced under a tilt-hammer to a section ³⁄₈ inch square. These were coiled with only ¹⁄₄ inch space between the coils, so that in case a spring broke within the hammer it could not get out of place. These springs were exceptionally durable. We took off the back cross-bar occasionally—perhaps once a month—to examine for broken springs, and sometimes we found one, which was replaced with a new one because we assumed that it was fatigued, but the hammers[16] worked just as well with broken springs as they did with whole ones. The springs, having considerable initial compression, did not become loose.

It seems proper to add that, except the help from Mr. Banks, I did not in designing the machine or organizing the work receive assistance or suggestion from anyone.

With these details I bid a final good-by to you, my old schoolmaster. I have a warm place in my heart for you. You set me my first lessons in mechanics. Your life was short. You were not ordained to cut much of a figure in the world. But you were faithful. You always did your work and did it well.

[17]

CHAPTER II

The Evolution and Manufacture of the Central Counterpoise Governor. Introduction of Mr. Richards.

When the stone-dressing machine was started a difficulty presented itself. The governor was in constant motion a short distance up and down, causing the engine to oscillate, running alternately too fast and too slow. There was nothing that should have caused this action, so far as I could observe. The load on the engine was constant. However the work done on the stone may have varied, the work of the engine was to lift the hammers, and these, being lifted successively, presented a uniform resistance. The oscillation was not very great, as nearly as I can remember about 12 per cent. of the speed; which would give to each hammer a variation of thirty-six blows per minute. This, however, produced a waving surface on the stone. The more rapid the blow, the stronger it was and the deeper the cut. These waves were slight, only about ¹⁄₅₀ of an inch variation in depth, but yet it was not possible for our rubbing-machine to grind them off without great loss of time. So we had to employ three or four stone-cutters to chisel off these ridges, which were about 4 inches apart.

It was evident that this oscillation must be stopped. I tried to remedy it by changing the pressure of the steam, and then by changing the pulleys so as to run the engine faster, the speed of the governor, however, necessarily remaining the same. But these had no effect. Having exhausted my own stock of ignorance on the subject, I applied to professional experts for more, and I got it. Three persons, who I supposed ought to know, and who probably did know, all that was then known on the subject, gave me the same advice. It was that I should get a larger engine and a[18] great deal larger fly-wheel. This advice did not seem to me reasonable. I knew that the engine was large enough, because while the governor was in the lowest position, in which it did not open the throttle entirely by any means, the machine ran too fast. They then told me I must have a heavier fly-wheel at any rate, and they explained to me that the fly-wheel performed two offices—one to carry the crank over its dead centers with an approximately uniform motion, and the other to give the governor time to act. I replied that the engine passed its dead centers with absolute uniformity then, as nearly as I could see, and as was shown by the surface of the stone, and consequently for that purpose the fly-wheel I had must be sufficient. The oscillations were regular, occupying about 30 revolutions of the machine, or 6 seconds of time, and had no connection with the dead centers, and I did not see why the governor should require any time to act. They told me that all governors required time to act, of course.

I then examined the governor more critically, and made up my mind that its action was hindered by friction in the driving-joints at the top of the spindle. These joints were about 4 inches apart, on opposite sides of the spindle, and were of a character in which the force transmitted through them to drive the balls produced a pinch between the broad faces of the joints. The governor could not act until by change of its speed it had accumulated force enough to overcome this pinch, and then it moved too far. Again I applied to my authorities for some way of getting rid of this friction. They told me that was easy enough. All I had to do was to put a yoke on the governor spindle, through which the governor arms were threaded and by which the driving pressure was applied close to the balls. So for the first time I took their advice and had a yoke put on the governor. I could not discover that this helped the matter at all. The improvement was too trifling to be noticed. I also saw clearly enough why this was so. The pressure applied was lighter than that applied through the joints, but it was also applied at a correspondingly increased distance from the axis, so that the effect in retarding the action of the governor was substantially the same.

I saw that if I got any relief I must find a way to it myself. So I began studying the subject of governors. My engineering[19] library at that time consisted of Haswell’s Engineers’ Pocket Book. What little book-knowledge I had respecting mechanics I had learned from Haswell. I turned to Haswell and read what he had to say about governors. I learned that they were conical pendulums and made half as many revolutions in a minute as the vibrations of a pendulum whose length was equal to the height of the cone, the base of which was the plane in which the center of oscillation of the balls and arms revolved, and its apex the point of intersection of the axes of the arms, if produced upward, and that their revolutions varied inversely as the square root of the height of this cone. I did not see that this got me out of my difficulty at all. I then referred to the subject of centrifugal force, with which I had made some acquaintance before, and I read this champion mind-muddler: “All bodies moving around a center or fixed point have a tendency to fly off in a straight line. This is termed centrifugal force.” This did not help me any more, nor interest me much at that time.

But I read further that the centrifugal force of a body revolving in any given circle varies as the square of the speed. “Thus a body making 10 revolutions per minute will exert four times as much centrifugal force as will be exerted by the same body making 5 revolutions per minute.” The governor on my engine was making 50 revolutions per minute, and in thinking the matter over it occurred to me that if the governor could be run as fast as my machine, namely, at 300 revolutions per minute, the centrifugal force of one pound would be as great as that exerted by 36 pounds at 50 revolutions per minute. I cried, “Eureka! I have found it.” One-pound balls in place of 36-pound balls would be easily driven. I told my experts of the great find that I had made, and they laughed at me. They told me I ought to know that the momentum of the balls increased in the same ratio with their centrifugal force, MV² being the expression common to both, so, in the same circle, while the centrifugal force of the balls at 300 revolutions per minute would be 36 times greater than at 50 revolutions, it would require also 36 times the force to drive them, and that I would gain nothing by my proposed change, but instead I would have to rotate also the weight that I would need to use to hold the small balls down, and the last case[20] would be worse than the first. This staggered me, and I pondered awhile what I should do.

I had a friend living near by on Fourteenth Street, west of Seventh Avenue—a Mr. Thompson, a mathematician and the author of a series of mathematical books then largely used. So I called upon him and stated my trouble and asked his advice. He illuminated the subject to me as follows: “You seem to be a persevering young man; keep hard at it and you will solve the difficulty by and by.”

In my despair I just had before me this one thought: The friction must be cured at any rate. After a time I thought that if I made a long joint at the top embracing the center of gyration of the counterpoise, so that the pressure required to drive the balls and counterpoise would be applied at some distance from the axis of the spindle and for that reason would be much lighter, and also would be normal to the surface of the joint-pin instead of being a pinch between opposite faces, the difficulty would be cured, as the force to overcome the friction would be exerted at the ends of levers 50 or 100 times the radius of the pin. I felt so sure of this that I risked making a governor with a single joint at the apex of the cone, as originally employed by Watt, thus making the governor more sensitive, as the height of the cone would not be changed at both ends, still fortunately holding to my little balls and high speed, though I cannot tell why. The joint at the top I made 6 inches in length.

When this governor was started, the trouble absolutely vanished. The engine ran with perfect uniformity while the load was constant. I use the adjective “perfect” advisedly, for the governor slide was as motionless on the spindle as if it were screwed tight, and the governor proved to be the most sensitive possible index of the variations of speed. When the belt was thrown off to the loose pulley the engine ran idle. The counterpoise then rose promptly but gently to its fixed highest position, and stood there motionless until the belt was thrown on and the hammers were started, when it moved as gently but promptly down to its lower position and stood there again motionless so long as the hammers were running. We could not detect by the eye the variation in speed that caused this action of the governor. The heaviest load[21] on the engine, however, was dragging rapidly the two tables loaded with stone. This caused the governor to settle still further, but always the motion of the engine seemed to be the same so far as I could detect. The surface produced on the stone left nothing to be desired. The machine cut true planes, free from any windage, and the surfaces were left so smooth that the rubbing-machine had but little to do, and kept up with the cutting-machine very easily. The governor fascinated everybody who witnessed its operation.

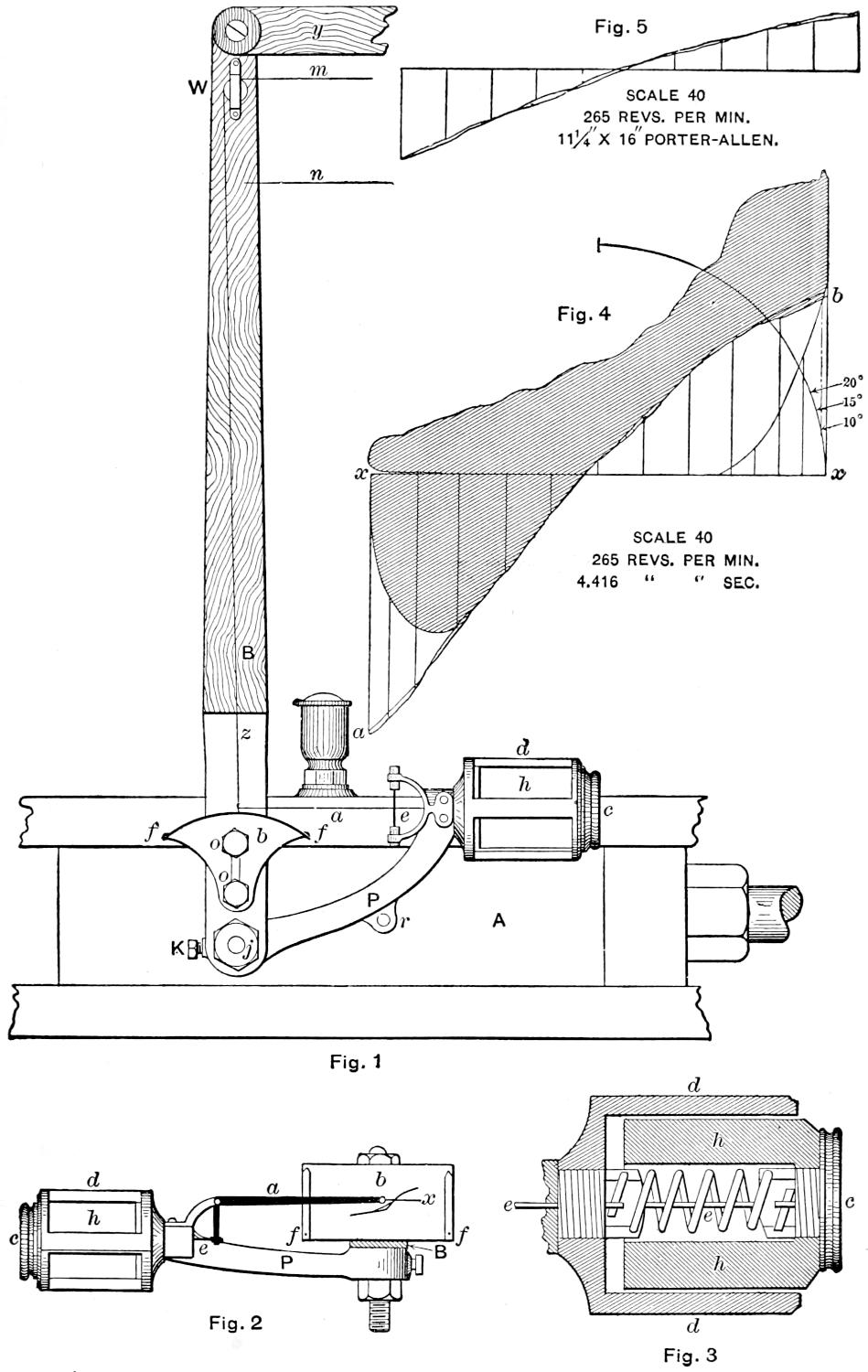

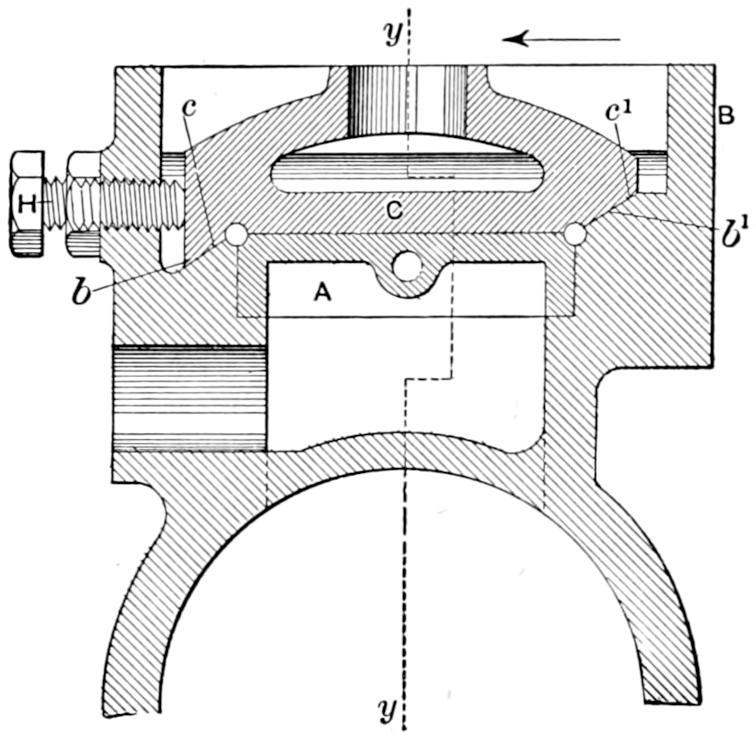

The First Porter Governor.

I first made the drawing for the governor with the weight hanging to the slide. Mr. John McLaren, a machinist who had done[22] good work for me, when I showed it to him said, “Why don’t you turn your weight upside down and put it between the arms?” I was not long in acting upon this suggestion, and that made the Porter governor complete. I had it described and illustrated in the Scientific American. They took a photograph of it as photographs were taken in those days—that is, they sent their artist up to make a sketch of it, and this sketch (shown here) and description will be found in the Scientific American of October 9, 1858. This governor has never been changed by me except in the shape of the counterpoise.

I believed the mathematics of my advisers to be sound, and that the perfect action of the governor was obtained entirely by the long driving-joint, which I supposed would have enabled the 36-lb. balls at 50 revolutions per minute to do just as well as 1-lb. balls at 300 revolutions, but I never tried the experiment.

In that belief I remained for 50 years. Now, at the age of over 80 years, after long rest from business activities, in revising these reminiscences for publication, the idea has first occurred to me, and has grown into a conviction, that my advisers were wrong here as they had been in every other respect. They overlooked the fact that the angular velocity of the driving-joint increased equally with that of the balls, so that the ratio between them would remain constant. The law that the driving force required increases as the square of the speed imparted applies only to the original source of power, as, to the force of the steam exerted in the cylinder of an engine, the motion of the piston remaining the same, and to the transmitting belts or gears whose speed also remains the same. At all these points the force exerted must increase as the square of the speed imparted; but this does not apply to the pressure exerted in the governor joint. Its speed does not remain the same, but increases with that of the balls. So, while the centrifugal force of the balls, changes in which produce the vertical movements of the counterpoise, varies as the square of the speed, the force required to be exerted in this joint to drive the balls, and which produces the friction to retard these movements, does not increase at all, whatever the speed of revolution may be. This fact, unobserved by me or any one else so far as I ever heard, has all the time been the secret, a pretty open[23] secret when once seen, of the surprising combination of sensitiveness and stability in the action of this governor which has led to its general use, and at which I myself have never ceased to wonder because I was ignorant of its cause. This, however, was not the only time that I builded better than I knew.

I can imagine some persons, after having read the above explanation, to say, some of them perhaps flippantly, and some possibly sneeringly, “To a properly educated engineer this is obvious at a glance.” I think it will be so hereafter, but has it been so hitherto? If any one will produce the record of its observation I will cheerfully yield to him the priority and will congratulate him upon it.

Some things, however, make me doubt if this observation has ever been made. At the London Exhibition of 1862 this governor attracted much attention from its novel appearance, rapid rotation and remarkable action. Many engineers spoke to me about it. In their conversation I observed two things: first, no one ever asked me a question, but every one explained its action to me; and second, while each had an explanation of his own to make, they all agreed in a fundamental respect. Their minds ran in the same groove. They considered the governor only in its theoretical action. No one ever took notice of the incident of friction, which was the controlling factor. An improved governor was in their view one contrived in some way to free the governor from the limitation to its action, which is imposed by the law of the conical pendulum, and every one explained to me how my governor was adapted to do this.

The following illustrates this universal view among English engineers:

In the Appendix to the 10th edition of Rankine’s “Manual of the Steam-engine and other Prime Movers,” published in 1882, one reads as follows: “Isochronous governors. The ordinary governor is not isochronous; for when, in order to adapt the opening of the regulating-valve to different loads, it rotates with its revolving pendulums at different angles to the vertical axis, the altitude of the cone assumes different values, corresponding to different speeds. The following are expedients for diminishing or removing this defect.

[24]

1. Loaded Governor (Porter’s).—From the balls of the common governor, whose collective weight is (say) A, let there be hung by a pair of links of lengths equal to the pendulum arms, a load, B, capable of sliding up and down the spindle, and having its center of gravity on the axis of rotation. Then the centrifugal force is that due to A alone, and the effect of gravity that due to A + 2B; consequently the altitude for a given speed is increased in the ratio A + 2B : A, as compared with that of a simple revolving pendulum; and a given absolute variation of altitude in moving the regulating-valve produces a smaller proportionate variation of speed than in the common governor.”

That is the whole of it. Respecting this I have to say:

1st. The vertical motion of the counterpoise (variation of altitude), if the links had also a single joint at the bottom, could not be either more or less than twice that of the balls, which equal lengths of the arms and links give also in the common governor, so in this respect the governor is no improvement.

2d. No notice is taken of the small size of the balls or of the speed of rotation.

3d. Professor Rankine is not responsible for this absurd piece of reasoning.

4th. It only shows how far the English engineering mind has been from considering the subject of hindrance to the governor action from friction.

My governor works within the law of the conical pendulum. I never dreamed of attempting in this form of governor to avoid it. In fact it is this law which gives to the governor its action. A change of speed is necessary to produce a motion of the counterpoise. But as the governor was designed by me, this change of speed is very small, probably no more than is required for stability, and is not sensible in any way except in the motion of the counterpoise itself, which is simultaneous with the most minute changes of speed.

Quite a variety of modifications of this governor are being made in this country, but I think not elsewhere. The makers have been kind enough to invent the name “the central counterpoise governor.” For this I feel greatly obliged, as I should be mortified to find my name attached to any of them. Their action[25] is always more or less unsatisfactory, sometimes very much so. But I do not think it likely that the secret of the remarkable action of the Porter governor has been detected by any of these people.

I am glad that this was not explained to me at first; if it had been I might not have thought of the single long driving-joint, which is a valuable feature.

When the stone-dressing machine proved to be valueless, as already described, I found myself out of business; but the governor had attracted so much attention and had been so favorably received that I thought I could establish a business of manufacturing these governors, and I am proud to say that the gentlemen already associated with me and who had lost their money in the abandonment of the stone-dressing machine were so decidedly of the same opinion, and I had won their confidence to such an extent, that they furnished the money to enable me to establish this manufacture.

I rented a shop on the second floor of a triangular building on Thirteenth Street, at the junction of Hudson Street and Ninth Avenue, owned by Mr. Herring, the safe-manufacturer, the lower part of which was occupied by him for his own business. This was a large room and had light on three sides.

I proceeded to equip this shop with the necessary tools, some of which I purchased of Mr. Freeland, then considered the best toolmaker in the United States, and who had gone to England and worked for some years as a journeyman in the celebrated Whitworth Works, in Manchester, for the purpose of learning everything that was known there. Those which Mr. Freeland could not supply I obtained from Geo. S. Lincoln & Co., of Hartford, Conn.

During the time these tools were building I was waited upon by Mr. Chas. B. Richards, who was then removing from Hartford to New York to establish himself as a designer of machinery, and who brought me a letter from Geo. S. Lincoln & Co. I was at that time engaged in scheming as well as I could a machine for drilling the arms and balls and counterweight and spindle of my governor, and immediately employed Mr. Richards to assist me in getting out the drawings for this machine. This he did quite to my satisfaction,[26] and the machine was made by Geo. S. Lincoln & Co., Mr. Pratt, for so many years head of the firm of Pratt & Whitney, afterwards the Pratt & Whitney Company, being then their foreman; so that all my tools from that concern were made by Mr. Pratt. He also cut for me superb iron patterns for the governor gears.

This machine always interested me very much. It solved every problem which was involved in the perfect and rapid performance of these operations. It had two parallel spindles running horizontally in the same plane, one fixed and the other adjustable. Distance pieces laid between the spindle heads insured the equal length of the arms of all governors of the same size. The table was made with a back to it, so that, a parallel block being laid on the table behind the arms, these were always brought in position parallel with its back. The arms were supported on blocks of proper height. These provisions insured that the joint-holes, which were drilled simultaneously, should intersect the axes of the arms and of the balls and spindle at right angles. This machine fitted up all the governors that I ever made. I gradually built up an excellent business in their manufacture, on account of the extreme pains taken to produce perfect work, so that the governors always gave the highest satisfaction.

I think of only one instance to the contrary. I sold a governor to Mr. Winslow, of Troy, afterwards of the firm of Corning & Winslow, the first manufacturers of Bessemer steel rails in this country under the inspiration of Mr. Alexander L. Holley. Soon after this governor had been shipped I received a letter from Mr. Winslow telling me that the governor would not answer at all, and I should come and see about it. I found the governor had been placed on a second-hand Burden engine, which was a well-known type of horizontal engine at that time, made in Brooklyn. The engine had been built to make 50 revolutions per minute, but being a great deal too large for their use they had reduced the speed to 25 revolutions per minute, and the complaint was that every time the crank passed its centers the governor dropped to its seat. I told them what I thought the difficulty was; that any one could see that the engine very nearly stopped as the crank passed its centers, and the governor had to drop. To show them this action, I disconnected the governor from the valve and throttled the engine by hand, and showed them that the governor, when not connected with the throttle-valve, rose and dropped on every stroke, in the same way as when connected. They asked me what I was going to do about it. I told them I should do nothing about it; that I presumed they might possibly get a governor somewhere that would stand that alternation of speed without winking, but they had better send mine back, because it was not made for any such service.

Charles B. Richards

A.D. 1858

[27]

The following is an amusing illustration, doubtless an extreme one, of the degree in which the lay mind may be incapable of mechanical perception. My governors were usually set on the engine bed of horizontal engines near the shaft, and were connected with the throttle-valve over the cylinder by means of a bell-crank lever and a long rod. One day a gentleman called to make a personal examination of the governor and its manufacture, with a view to investing in the business. I showed him a governor in action on the testing platform, and a woodcut on my circular which represented the governor in its position, as above described, with a short piece of the connecting-rod attached to the lever. He looked at this cut intently for some time, and then, putting his finger on the broken-off end of the little rod, said, “Ah, I see; the steam enters there.” I made no reply, and he was so much pleased with his own penetration that he invested at once.

I know of only one case in which this governor needed the help of a dash-pot or controlling vessel. In the great plate-mill of the Otis Works, in Cleveland, when the enormous mass of steel struck the rolls, the governor dropped sharply to its seat, and jumped as sharply to the upper limit of its action when this mass was shot out. Mr. Wellman, their general manager, suggested to me an elegant arrangement of air-chambers at the top and bottom of a cylinder, which permitted free motion to the governor through its whole range of action, but cushioned it on confined air at the ends.

For several years I made the counterpoise of the governor in the form of a vase. The present form with hemispherical top was suggested by Mr. Whitworth in 1866, and shown by me in the Paris Exposition of 1867. It has three advantages. It is[28] more readily turned with a circular tool-rest, and it contains more metal and looks more mechanical.

I exhibited the governor in operation at a fair of the American Institute held on Fourteenth Street between Sixth and Seventh avenues, New York City (where the armory of the Twelfth Regiment now stands), making an arrangement with an exhibitor of an engine for that purpose. I remember that Mr. George H. Reynolds, then an engineer in the works of Mr. Delamater at the foot of West Thirteenth Street, as he passed it with a friend a day or two after it was started, remarked in my hearing, “It will take a horse-power to drive that governor.” It would not do to let any such nonsense get around as the opinion of an engineer, so the next morning the governor was driven by a belt ⁵⁄₈ of an inch wide, and continued to be so through the fair. I was sorry afterwards that I did not use a half-inch belt, which would have driven it just as well, and indeed I think even a narrower belt would have done, as the foot of the spindle was of hardened steel, a segment of a sphere, running in a puddle of oil in a hardened step cupped to a larger radius.

The funniest application of the governor I ever made was the following: The Civil War had just broken out, and every Yankee was making some warlike invention. The most ridiculous of all was a centrifugal gun. A company was formed for its manufacture. The shot, about an inch in diameter, was fed in at the center of a swiftly revolving wheel and thrown out through a barrel at the periphery, with a velocity that, it was estimated by the inventor, would carry it about two miles. This velocity was to be got up in about one second. The governor would not act quickly enough, and the engine was stopped. The parties heard of my governor, and ordered one, offering to pay for it in a tempting amount of their stock. I preferred the cash and got it. The governor filled the bill, the shot was delivered, the velocity of revolution not falling sensibly, but we judged by the sharp fall of the counterpoise that it required not less than twenty horse-powers to do it.

The gun was tried on the bank of the Hudson, the Palisades opposite being the target. The inventor declared that every shot hit the mark, but some evil-minded persons insisted that they[29] fell into the water within a quarter of a mile of the shore from which they were fired.

About the same time the absurdity of sending into the field a tank of water, a boiler, an engine and the gun, on separate wheels, connected by pipes or belting, which would be ruined by the least damage to anything, began to dawn on the enthusiasts, and the thing was abandoned.

I furnished one of my first governors to Mr. James Horner to regulate a rolling-mill near Boonton, N. J., a sale which is worth recording. This mill was employed in rolling steel pretty high in carbon into rods for making gimlets, and the three-high train had not yet issued from the brain of Mr. Fritz. The rolling was slow work. The resistance brought down the speed of the engine before the governor could act, and they could have only one pass in the rolls at a time. The workmen had to carry the end of the rod around and insert it in the next groove after it had run out of the former one. The rod would be black before it was finished, and often it was difficult to get it finished at all. I do not know of any change that so much impressed me at the time as did that which followed the putting of my governor on this engine. The full speed was kept up, the billets seemed to rush through the rolls, two and even three passes could be in them at the same time, and the rods were still at a dull red heat when finished.

This success induced me to make a raid on Pittsburg. I found there very different conditions. They then rolled nothing but iron, so far as I saw or heard. In the first mill I visited, after I had discussed the subject with one of the proprietors, an old man came up to me and said, “Do you see that chair? I have sat in that chair twenty-four years.” The chair corroborated his story. “I watch the rolls; when a bar enters them, I turn on more steam; when it goes out I shut it off. If you put in a governor that will do as well, I shall be discharged. I don’t know how to do anything else; I have a family dependent on me, and I don’t know what I should do.” I did not hesitate long about what I should do. I could not improve on the old man’s action. He regulated the speed perfectly. The only result of my success would be to beggar him. Superseding hand labor by machinery I did not in this particular case care to be responsible for. I concluded that[30] the Pittsburg way was good enough for them, and took the next train for home.

The first governor I sold was to Mr. William Moller for his sugar-refinery on Vandam Street. The engine to be regulated was an old-fashioned beam-engine. The governor was to be set on a bracket that we had to bolt to the wall, and a pulley some 3 feet or more in diameter had to be made in halves and put on the shaft. To make sure that no mistake would be made, I went down myself to make a gauge of that shaft. I took a ³⁄₈-inch steel rod bent to span the shaft, and made of this an outside gauge with great care. Now this was not what I wanted, but I did not know it. I wanted an inside gauge, representing the diameter of the shaft, and what I did make was useful only to compare the two.

I returned highly satisfied with my work, leaving the real gauge to be made in the shop, where it could not be compared with the shaft. What might reasonably have been expected to happen did happen. In some unaccountable way something happened to my gauge, and when we went to install the governor we found the pulley had been bored ¹⁄₄ inch too small. We had to work hard all night, and got through only just in time for the engine to start at its usual hour in the morning. If I had sent a man who knew his business to make this gauge I should have avoided a lot of trouble, but I should not have learned anything.

In preparing for the establishment of the governor manufacture I visited the works of Geo. S. Lincoln & Co., in Hartford, and saw twist-drills in use, cutting chips instead of scraping. They attracted my attention and I inquired about them, and was told that they made them themselves. They kindly took me into the smith-shop and had one made for me to witness the operation. The smith heated a round bar of steel and swaged channels in it on opposite sides. They had quite a set of top and bottom swages for different-sized channels. He then took another heat on the bar and twisted it by hand, giving a gradually increasing twist, which at the end was quite rapid. An increasing twist was obtained in this way. The drill was held in a vise, so that only the projecting end of it could receive the amount of twist then being imparted. The drill had to be moved in the vise of course a number[31] of times. The channels were smoothed out with files, and when the drill was turned in the lathe sharp cutting edges were developed, which needed only to be backed off by grinding. I took one of these drills home with me to serve as a pattern and equipped my shop with them. They were of the highest use to me. The small ones drilled the holes for the governor joints, and the large ones drilled the counterpoise and the column for the governor spindle. I suppose the twist-drill had its origin in these Hartford works.

I never saw any twist-drills in England except at Mr. Whitworth’s, and these I thought were the funniest things I ever did see. They were twisted by the blacksmith out of square bars and with a uniform quick twist, were left rough, and did not fill the hole, and the ends were flattened out in the form of the common drill to scrape, and not to cut.

When I returned from England in 1868 twist-drills were coming into general use in this country. After 1876 the firm of Smith & Coventry introduced them in England.

At that time almost everything in machine-shops was done in the old-fashioned way, and accuracy depended entirely on the skill of the workman. The tool work left much to be done by the fitter. Interchangeability was unknown, even in screw-threads. For example, when nuts were removed from a cylinder head, pains had always to be taken that each nut was replaced on its own bolt, as no two were exactly of a size. This condition developed a class of very skillful all-round workmen; but my earliest observation showed me that in manufacturing it was important that so far as possible the personal factor should be eliminated. I adopted the rule that in mechanical work there was only one way to insure that anything should always be done right, and that was to make it impossible that it should be done wrong. For example, in my governor gears their true running required that the bore should be absolutely correct, both in position and in direction. I had seen many gears bored. They were held in the jaws of a chuck and trued by marking their projecting side when running with a piece of chalk. It was evident that absolute truth could hardly ever be reached in this way, and the approximation to it depended wholly on the skill and pains of the workman.[32] Besides, much time was lost in setting each wheel. These objections were much aggravated in the case of bevel-gears.

I met these difficulties in this way. In standardizing my governors I found it necessary to make eight sizes, but managed to use only three different pairs of gears. I made a separate chuck for each of these six wheels, the faces of which were turned to fit the top and inner ends of the teeth, the same surfaces to which I had seen the chalk applied. When the castings were received from the foundry the first operation on them was to bed them to their chucks, which were covered with a thin coating of red lead for this purpose. The workman was careful to remove only projecting imperfections without touching the true surfaces of the teeth. After this the gears, being held firmly to their chucks by means of a yoke, were bored rapidly and always with absolute truth. Result: their running was practically noiseless.

Mr. Freeland taught me the secret of producing true cylindrical surfaces by grinding with a wheel. It was to let the swiftly revolving wheel traverse the surface as it rotated, touching only the highest points, and these very lightly. This avoided the danger of errors from the springing of either the piece or the wheel, which under strong pressure is sure to take place to some extent, even in the best grinding-machines. I have found this delicacy of touch to be a most difficult thing to teach the ordinary workmen. They often manage to produce by grinding a surface more imperfect than it was before.

I took extreme pains to insure that the axes of the joint pins should intersect the axis of the governor spindle and those of the governor balls, and should be equidistant from the center of the counterpoise, these parts of the joints having been turned to true spherical forms by means of a circular tool-rest. For this purpose I employed a feeling-gauge, consisting of a cylindrical stem fitting the hole as drilled, with a curved arm projecting from this stem and terminating in a point that would rub on the external surface of the balls. By this means we almost always detected some slight inaccuracy, which was remedied by the use of a round file. The joint holes were afterwards finished with long reamers, the cutting portion of which was in the middle of their length. The front end of the reamer fitted the drilled hole and extended[33] quite through the joint, so guiding the cutting edges as they entered, and the back end of the reamer filled the hole that had been reamed.

I finally tested their alignment by bringing the last of the five joints together after the others had been united, when the forked link should swing freely to the ball without the least tendency in either direction from its exact place. This it always did.